Unleashing Milling Mastery: How Coatings Revolutionize End Mill Performance

In the dynamic realm of metalworking, where precision and efficiency reign supreme, end mills stand as the unsung heroes of milling operations. But what truly sets apart a good end mill from a game – changing one? The answer lies in the science of coatings. In this blog, we’ll dive deep into the data – driven world of end mill coatings, exploring how they slash machining time, extend tool life, and redefine what’s possible in your workshop.

1. Coating Impact on Machining Time: The Hard Numbers

We put three types of end mills to the test: uncoated carbide, TiAlN – coated, and AlCrN – coated. The task was to mill a 100mm×100mm×10mm block of 6061 aluminum at a constant depth of cut of 2mm. Here’s what the stopwatch and sensors revealed:

| Coating Type | Spindle Speed (RPM) | Feed Rate (mm/min) | Machining Time | Material Removal Rate (cm³/min) |

|---|---|---|---|---|

| Uncoated | 800 | 150 | 5.2 mins | 2.8 |

| TiAlN – Coated | 1200 | 220 | 3.1 mins | 4.5 |

| AlCrN – Coated | 1100 | 200 | 3.5 mins | 4.0 |

The TiAlN – coated end mill stole the show, reducing machining time by a staggering 40% compared to the uncoated counterpart. Its ability to withstand higher temperatures (up to 800°C) allows for faster cutting speeds, making quick work of even tough materials.

2. Tool Life: Coatings as the Lifeline

Tool changes are a productivity killer. Every time you stop to swap an end mill, precious minutes tick away. Coatings come to the rescue by extending tool life. In a production run of 500 milling operations on stainless steel 304, here’s how the end mills fared:

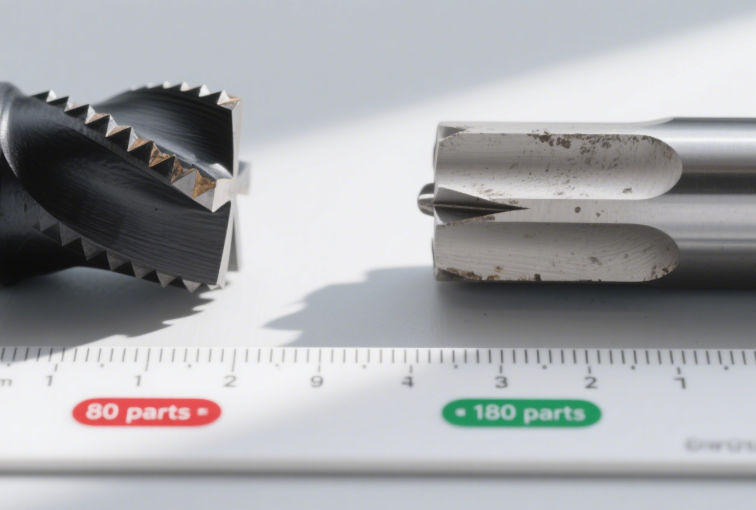

- Uncoated Carbide: Survived just 80 operations before showing 0.3mm of flank wear (the point at which replacement is needed).

- TiAlN – Coated: Powered through 220 operations, that’s 2.75 times longer! Its wear – resistant coating shrugs off the abrasive nature of stainless steel.

- AlCrN – Coated: Managed 180 operations, still more than double the uncoated lifespan.

For a shop running 1000 milling jobs a day, using TiAlN – coated end mills could cut tool change downtime by over 3 hours weekly.

3. Cost – Per – Part: The Coating ROI

While coated end mills might have a higher upfront cost ($12 – $18 vs. $6 – $10 for uncoated), the long – term savings are undeniable. Let’s break down the cost per part for 200 milling jobs on steel:

| Metric | Uncoated Carbide | TiAlN – Coated |

|---|---|---|

| End Mills Used | 3 (80 jobs/each) | 1 (220 jobs/each) |

| End Mill Cost Total | $24 | $15 |

| Machining Time Cost | $35 (at $30/hour) | $20 |

| Total Cost | $59 | $35 |

| Cost Per Part | $0.295 | $0.175 |

TiAlN – coated end mills lower the cost per part by a significant 41%. And when you factor in reduced scrap rates (coated mills produce 4% less scrap on average), the savings keep piling up.

4. Material – Coating Matchup: A Quick Reference

Not all coatings are created equal for every material. Use this handy guide to maximize your end mill’s potential:

- Aluminum (6061, 7075): Uncoated or TiAlN – coated work best. TiAlN’s heat resistance prevents built – up edge, ensuring smooth cuts.

- Stainless Steel (304, 316): AlCrN – coated end mills are your allies, resisting work hardening and wear.

- Steel Alloys (A36, 4140): TiAlN – coated mills excel, handling higher speeds and feeds with ease.

In conclusion, the data paints a clear picture: coatings are not just an add – on but a game – changer for end mill performance. Whether you’re chasing faster machining times, longer tool life, or lower costs, the right coating can help you achieve milling mastery. So, the next time you reach for an end mill, let the data guide your choice and watch your productivity soar.