U Drills: Material Machinability, Insert Selection, and Cutting Efficiency

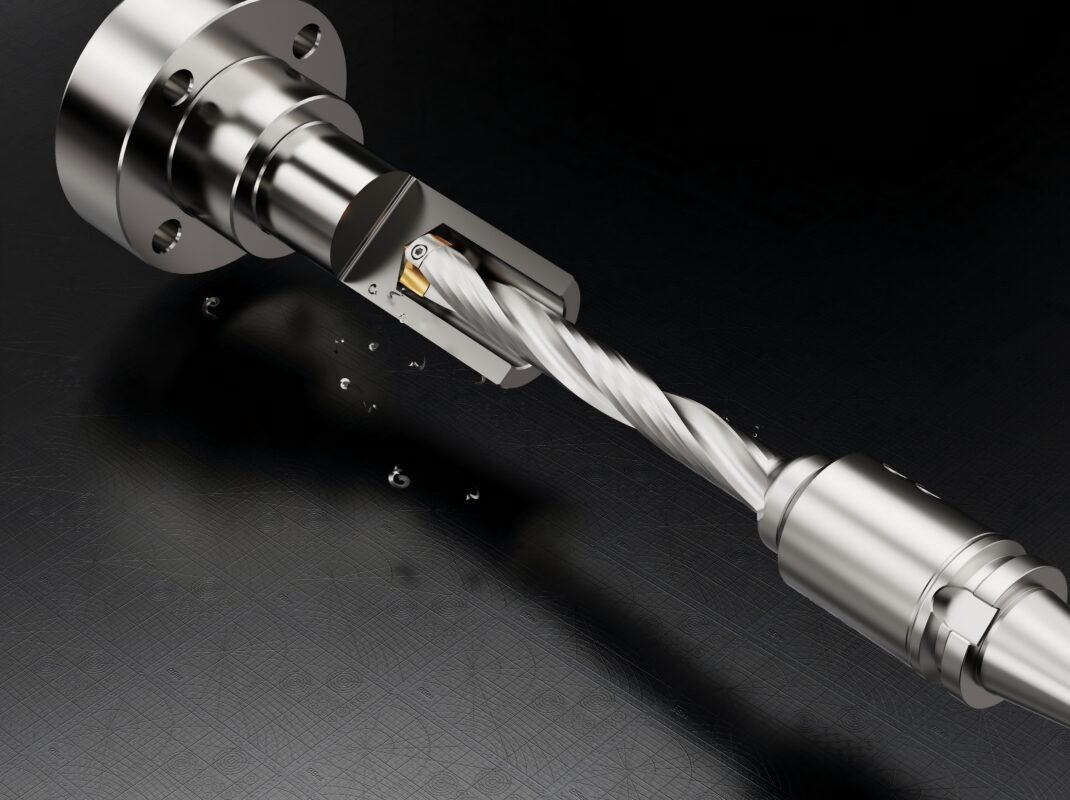

U drills, also known as indexable insert drills or spray drills, have revolutionized hole-making operations in the manufacturing industry. Their ability to drill deep holes with high efficiency and precision makes them a preferred choice for many machinists. Let’s explore their performance in machining different materials, the suitable inserts to pair with them, and how cutting speed impacts efficiency.

Machining Different Materials with U Drills

Steel

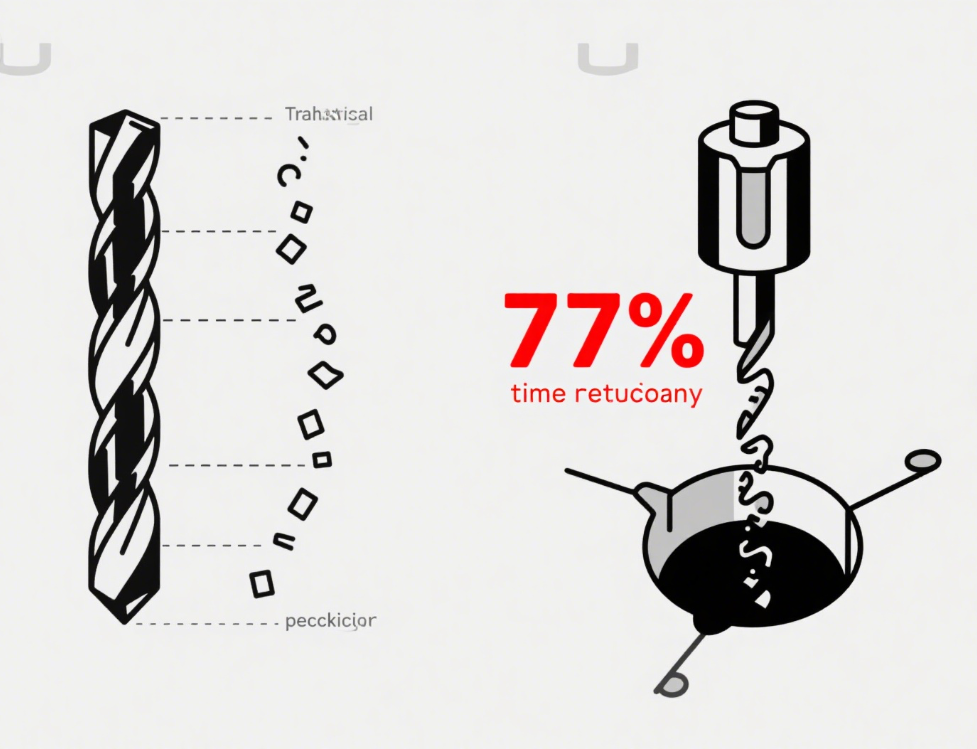

U drills excel in machining various types of steel, including carbon steel, alloy steel, and tool steel. The robust design of U drills, combined with the right inserts, allows for efficient chip evacuation and heat dissipation. When drilling carbon steel, U drills can achieve high feed rates and cutting speeds, reducing cycle times significantly. For example, when drilling a 20mm diameter hole in A3 carbon steel, a U drill can complete the task much faster than traditional twist drills.

Stainless Steel

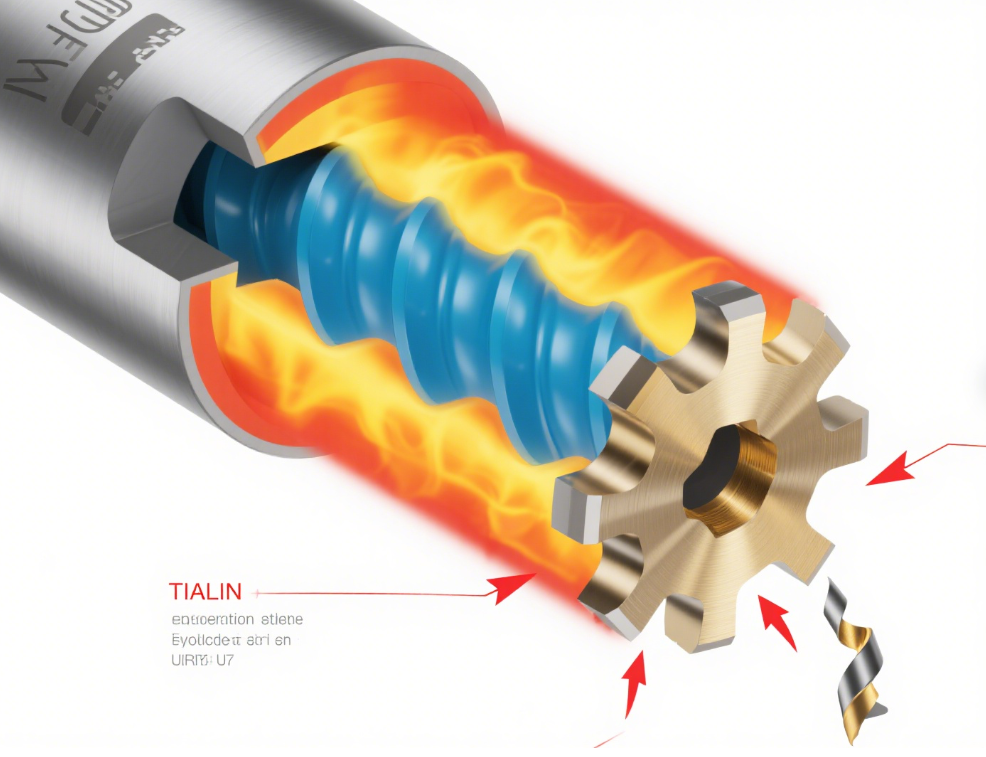

Stainless steel presents challenges in drilling due to its work-hardening nature and poor thermal conductivity. However, U drills, when paired with inserts specifically designed for stainless steel, can overcome these issues. Inserts with high wear resistance and thermal stability help in maintaining cutting performance. The internal coolant supply of U drills is crucial here, as it directs coolant precisely to the cutting edge, reducing heat and preventing built-up edge.

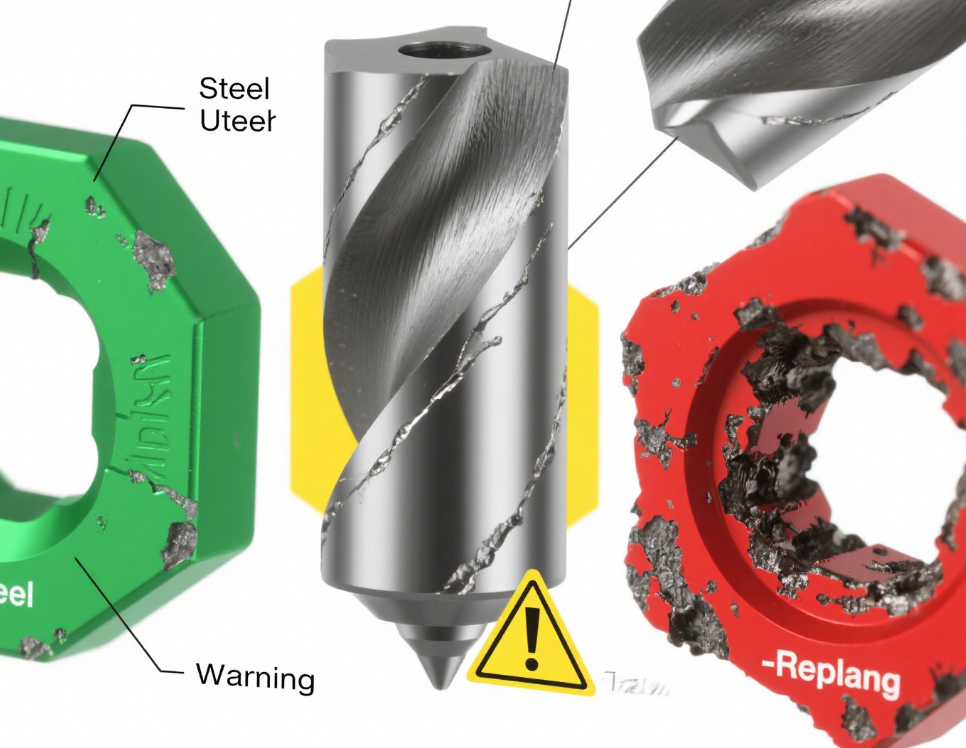

Cast Iron

Cast iron is relatively easier to drill compared to stainless steel, but it is abrasive and can cause rapid tool wear. U drills with inserts featuring wear-resistant coatings, such as diamond-like carbon (DLC) or titanium nitride (TiN), are ideal for cast iron. The strong cutting edges of these inserts can withstand the abrasive nature of cast iron, ensuring longer tool life and consistent hole quality.

Insert Selection for U Drills

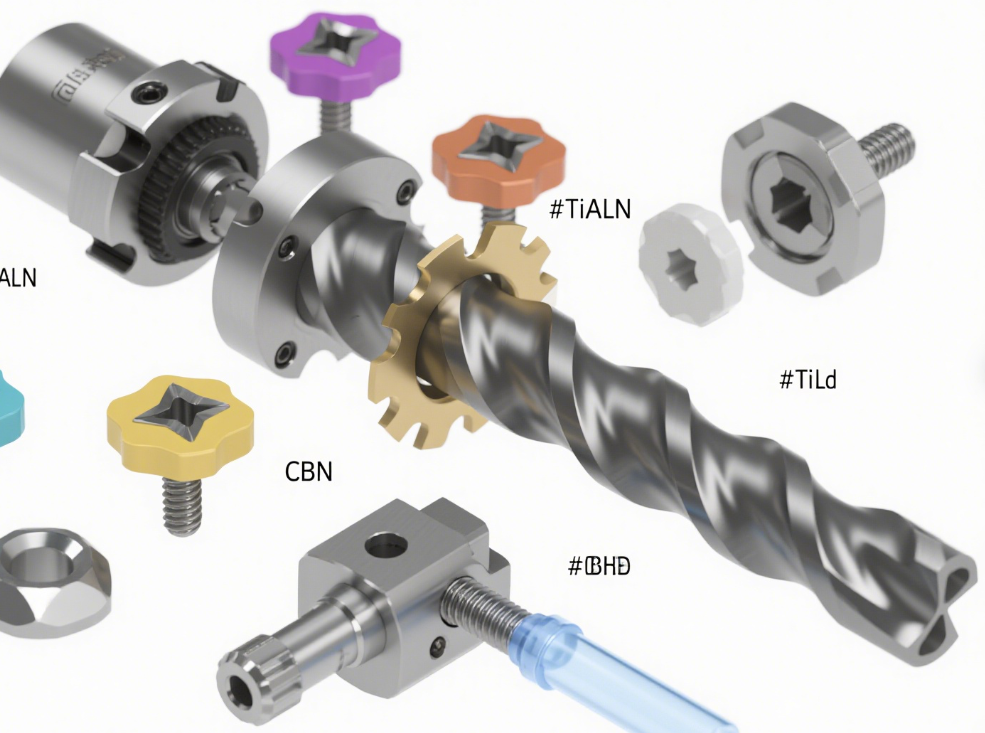

Carbide Inserts

Carbide inserts are the most common choice for U drills due to their high hardness and wear resistance. They come in various grades, each suitable for different materials. For general-purpose drilling in steel, a medium-grade carbide insert works well. When machining harder materials like hardened steel or stainless steel, a higher-grade carbide with enhanced toughness is preferred.

Ceramic Inserts

Ceramic inserts are used for high-speed drilling of materials like cast iron and some non-ferrous metals. They can withstand extremely high temperatures, allowing for much higher cutting speeds than carbide inserts. However, they are more brittle and require stable machining conditions.

CBN Inserts

Cubic Boron Nitride (CBN) inserts are reserved for drilling very hard materials, such as hardened steel (above 50 HRC). They offer exceptional wear resistance at high temperatures, making them suitable for precision drilling in hard materials where other inserts would quickly wear out.

Cutting Speed and Efficiency

Optimal Cutting Speeds

The optimal cutting speed for U drills depends on the material being drilled and the type of insert used. For steel with carbide inserts, cutting speeds typically range from 80 – 150 m/min. When using ceramic inserts on cast iron, speeds can go up to 200 – 300 m/min. For stainless steel, due to its challenging machining properties, cutting speeds are lower, usually between 50 – 100 m/min.

Efficiency Enhancements

U drills offer several efficiency advantages over traditional drills. Their indexable inserts allow for quick replacement when worn, reducing downtime. The internal coolant system ensures efficient heat removal, which not only prolongs tool life but also allows for higher cutting speeds and feed rates. Additionally, U drills can drill deeper holes in fewer passes, further increasing productivity. For example, a U drill can drill a 100mm deep hole in one pass, whereas a twist drill might require multiple pecking cycles.

U drills have transformed hole-making by offering superior performance in terms of material machinability, insert versatility, and cutting efficiency. By selecting the right insert for the material and optimizing cutting speeds, manufacturers can achieve significant improvements in productivity and cost-effectiveness.