Turning Tools Mastery: Pro Tips to Boost Efficiency & Precision

In the world of CNC turning and manual lathe work, the performance of your turning tools directly impacts productivity, surface quality, and tool life. Whether you’re machining steel, stainless steel, or aluminum, mastering a few key techniques can transform average results into exceptional ones. This blog shares actionable 干货 (dry goods—practical tips) to optimize your turning operations, from tool selection to parameter tuning.

1. Choose the Right Tool Material & Coating: Match the Material

The first rule of efficient turning is selecting tools engineered for your workpiece material. Using the wrong tool leads to rapid wear, poor finishes, and frequent replacements—wasting time and money.

- Carbide Inserts: The workhorse for most metals. Opt for uncoated carbide for non-ferrous metals (aluminum, brass) to avoid built-up edge (BUE). For ferrous metals (steel, cast iron), coated carbide (TiAlN, TiCN, or AlCrN) is a game-changer:

- TiAlN coating: Handles high speeds (up to 300 m/min for steel) and resists heat—ideal for general steel turning.

- AlCrN coating: Excels with stainless steel (tough and heat-resistant) by reducing crater wear.

- Cermet Inserts: Perfect for finishing hardened steel (HRC 45–55) at moderate speeds, delivering mirror-like surfaces.

- Ceramic Inserts: Use for ultra-hard materials (HRC 55+) or high-speed roughing of cast iron—they withstand extreme temperatures but are brittle, so avoid shock.

Pro Tip: For tricky materials like Inconel (aerospace alloys), choose cubic boron nitride (CBN) inserts—they maintain hardness at 1,000°C+ and resist chemical wear.

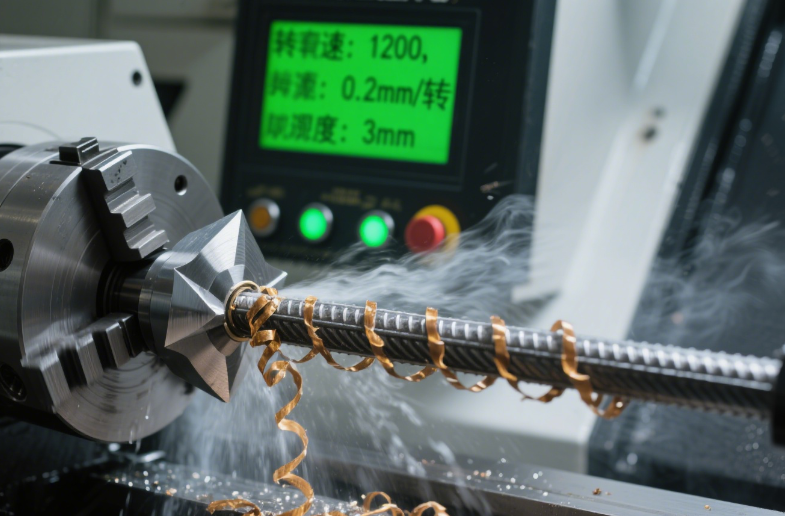

2. Optimize Cutting Parameters: Speed, Feed, & Depth of Cut

Even the best tools underperform with mismatched parameters. The “golden triangle” of RPM, feed rate, and depth of cut (DOC) must balance material removal rate (MRR) with tool longevity.

- RPM (Spindle Speed): Calculate based on workpiece diameter and material:

- Formula: RPM = (Cutting Speed × 1000) / (π × Diameter).

- Examples:

- Aluminum: 1,500–3,000 RPM (use high speed to avoid BUE).

- Mild steel: 800–1,500 RPM (carbide inserts).

- Hardened steel: 300–800 RPM (ceramic or CBN inserts).

- Feed Rate: Too slow causes rubbing (tool wear); too fast risks chipping. Aim for:

- 0.1–0.3 mm/rev for roughing (maximize MRR).

- 0.05–0.1 mm/rev for finishing (smooth surfaces).

- Depth of Cut (DOC):

- Roughing: 2–5 mm (remove bulk material quickly; avoid shallow cuts that “skate” on work-hardened layers).

- Finishing: 0.1–0.5 mm (light pass to eliminate tool marks).

Pro Tip: Use high-feed turning for roughing—shallow DOC (0.5–1 mm) with ultra-high feed rates (0.3–0.8 mm/rev) reduces cycle time by 30%+ on tough materials.

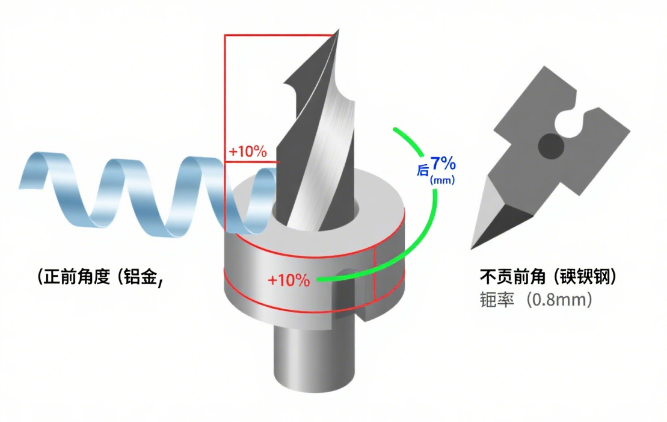

3. Tool Geometry: Sharpen the Edge (Literally)

The shape of your turning tool’s cutting edge (rake angle, relief angle) determines how cleanly it slices through material.

- Rake Angle:

- Positive rake (+5° to +15°): Sharp, low cutting force—great for aluminum and soft metals (reduces BUE).

- Negative rake (-5° to -10°): Stronger edge, better for hard steel or interrupted cuts (avoids chipping).

- Relief Angle: Ensures the tool’s flank doesn’t rub against the workpiece. Use 5°–10° for general work; increase to 12° for soft metals.

- Nose Radius: A larger radius (0.8–1.2 mm) improves surface finish but increases cutting forces. Use 0.4 mm for tight corners.

Pro Tip: For stainless steel (which work-hardens rapidly), use a high-positive rake tool with a polished flute to reduce friction and heat.

4. Rigidity is King: Minimize Vibration

Vibration (chatter) ruins surface finishes, accelerates tool wear, and even damages machine spindles. Fight it with these steps:

- Shorten Tool Overhang: Keep the tool 伸出 (伸出 —overhang) from the holder to 2–3× its diameter. Use a rigid tool holder (e.g., square shank) instead of round for extra stability.

- Clamp Workpieces Securely: Use a 3-jaw chuck for round stock; add a steady rest for long, thin shafts to prevent deflection.

- Reduce Spindle Speed: If chatter starts, drop RPM by 10–20%—resonance often occurs at specific frequencies.

Pro Tip: For long workpieces, use a follow rest to support the cutting zone—this eliminates “whip” and allows heavier cuts.

5. Coolant: More Than Just Cooling

Coolant does three critical jobs: cools the tool/workpiece, lubricates the cutting edge, and flushes away chips. Use it wrong, and you’ll waste its benefits.

- Flood Cooling: Best for general turning—direct the nozzle to the cutting zone (where the insert meets the workpiece), not just the tool body.

- Mist Cooling: Ideal for high-speed aluminum turning—combines air and minimal coolant to reduce friction without causing thermal shock.

- Dry Turning: Only for cast iron (it’s self-lubricating with graphite). Avoid for steel/stainless—heat will destroy inserts.

Pro Tip: For deep-hole turning, use high-pressure coolant (HPC) (30–100 bar) to blast chips out of the hole and cool hard-to-reach areas.

6. Monitor Wear & Extend Tool Life

A dull tool forces you to slow down, ruins finishes, and risks workpiece damage. Learn to spot early wear:

- Flank Wear: A smooth, even wear band on the tool’s flank is normal—replace when it reaches 0.3–0.5 mm (varies by material).

- Crater Wear: A concave depression on the rake face (common in high-speed steel turning) signals excessive heat—reduce RPM or switch to a coated insert.

- Chipping: Cracks or missing bits on the cutting edge mean too much feed, poor rigidity, or wrong insert material.

Pro Tip: “Index” inserts (rotate to a new edge) at the first sign of wear, not when they’re completely dull. This prevents overheating and extends insert life by 20%+.

Final Results: Efficiency Boost in Action

By applying these tips, a mid-sized workshop machining 100 steel shafts daily reduced tool changes by 40%, cut cycle time per part by 15%, and improved surface finish from Ra 3.2 to Ra 1.6—eliminating the need for post-machining polishing.

Turning tools are more than just cutting edges—they’re investments. Treat them with precision, match them to the job, and tune your process, and you’ll unlock consistent, efficient results.