Turning Inserts: The Precision Powerhouse in Modern Machining

Unlock Efficiency, Accuracy, and Cost Savings in Lathe Operations

1. What Are Turning Inserts and Why Do They Matter?

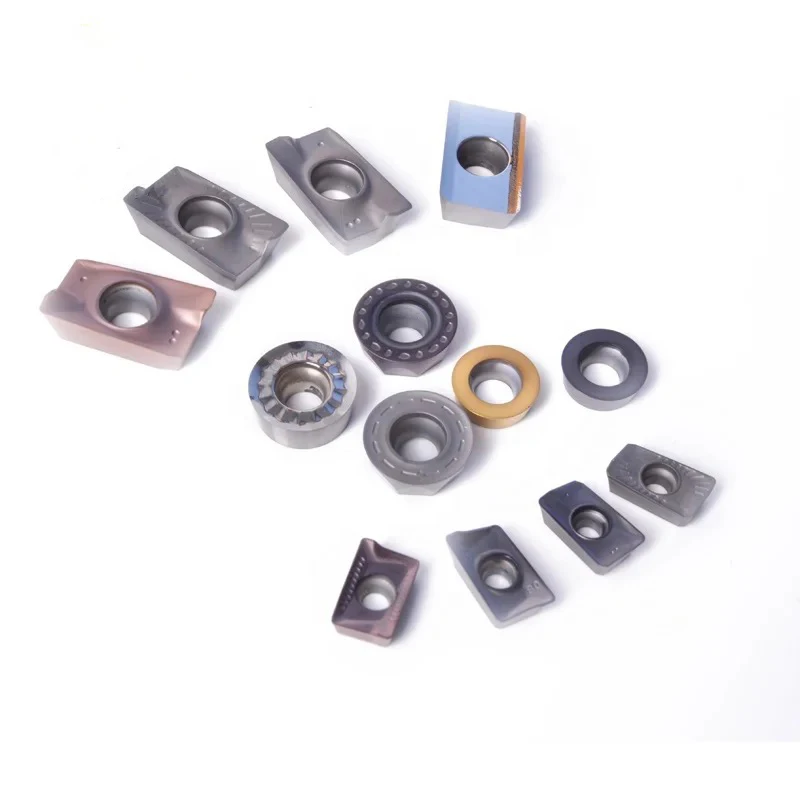

Turning inserts are indexable cutting tools mounted on lathe tool holders to shape rotating workpieces. Unlike traditional welded tools, these replaceable inserts combine advanced materials (e.g., carbide, ceramics) with precision-engineered geometries to deliver superior cutting performance. Their significance lies in three pillars:

- Cost Efficiency: Reduce downtime by replacing worn edges in seconds instead of resharpening entire tools39.

- Precision Control: Achieve tolerances ≤±0.01 mm for critical applications like aerospace shafts or medical implants14.

- Material Versatility: Machine everything from aluminum to Inconel with optimized insert grades9.

2. Core Materials & Technologies Driving Performance

Material Innovations

- Carbide Inserts: Dominant for general use; combine tungsten carbide with cobalt binders for wear resistance. Ideal for steel, cast iron, and stainless steel79.

- Ceramic Inserts: Excel in high-speed machining (≥1,000 m/min) of superalloys and hardened steels1.

- CBN/Diamond Inserts: For ultra-hard materials (e.g., hardened tool steels, composites), extending tool life 5× over carbide10.

Enabling Technologies

- Multilayer Coatings: Titanium Aluminum Nitride (TiAlN) or Aluminum Chromium Nitride (AlCrN) coatings reduce heat to 800°C and extend life by 200%49.

- Chipbreaker Geometries: Engineered grooves control chip flow, preventing entanglement and improving surface finish (e.g., achieving Ra 0.4 μm)411.

- Internal Cooling Channels: Deliver high-pressure coolant (70+ bar) directly to the cutting edge, reducing thermal deformation in deep-hole operations1.

3. Geometry & Classification: Matching Inserts to Applications

Turning insert geometry dictates cutting behavior, finish quality, and vibration resistance:

Table: Turning Insert Geometry Guide

| Shape | Best For | Strength | Weakness |

|---|---|---|---|

| Diamond (55°) | General turning | Balanced strength & versatility | Limited accessibility |

| Round (R-type) | Roughing & contouring | Highest edge strength | Poor surface finish |

| Triangle (T-type) | Threading & grooving | Tight-space access | Fragile cutting edges |

| Square (S-type) | Heavy roughing | Shock resistance | High power consumption |

Key Angles for Precision:

- Rake Angle: Positive angles (e.g., +7°) reduce cutting force for thin-walled parts; negative angles (−6°) bolster edge strength for interrupted cuts1011.

- Nose Radius: Larger radii (0.8–1.2 mm) improve finish but increase vibration; smaller radii (0.2 mm) suit fine detailing3.

4. Scientific Selection & Installation

Selection Methodology

Match inserts to your workpiece using this framework:

- 1.Material Hardness:

- Soft materials (Al, Cu): Sharp, polished edges with positive rake angles.

- Hard materials (Ti, Inconel): Reinforced edges with heat-resistant coatings9.

- 2.Operation Type:

- Finishing: Fine-grain inserts with honed edges.

- Roughing: Robust chipbreakers for high material removal rates (500+ cm³/min)11.

- 3.Machine Rigidity: Low-stability setups (e.g., long overhangs) demand inserts with vibration-dampening geometries1.

Installation Best Practices

- Clean Interfaces: Wipe holder seats with acetone to prevent insert slippage4.

- Torque Control: Tighten screws to 30–50 N·m—over-torquing cracks inserts; under-torquing causes chatter10.

- Runout Check: Validate ≤0.005 mm runout using dial indicators11.

5. Maximizing Insert Life: Maintenance & Troubleshooting

- Wear Monitoring:

- Flank Wear >0.3 mm: Replace insert to avoid workpiece damage.

- Cratering: Switch to coated grades for abrasive materials6.

- Edge Repositioning: Rotate triangular/diamond inserts to utilize all cutting edges (up to 6 edges per insert)7.

- Coolant Optimization: Emulsions with 8–12% concentration reduce built-up edge on aluminum5.

Common Failures & Fixes:

- Chipping: Use tougher substrate (e.g., carbide with 10% cobalt) or reduce feed rate.

- Thermal Cracking: Activate internal coolant or decrease cutting speed14.

6. Industry Applications: Precision Where It Counts

- Aerospace: Ceramic inserts machine turbine blades at 12x speed of carbide, maintaining ±0.025 mm profile tolerance1.

- Automotive: CBN inserts finish hardened crankshaft journals (HRC 60+) with Ra 0.2 μm roughness9.

- Medical: Micro-grain carbide inserts create bone screws with 0.01 mm thread accuracy3.

7. The Future: Smart Inserts & Sustainable Tech

- Sensor-Embedded Inserts: Real-time monitoring of cutting forces and temperature via IoT-enabled tool holders (e.g., Sandvik CoroPlus®)9.

- Nanostructured Coatings: Self-healing AlTiSiN layers increase tool life by 300% in titanium machining1.

- Recyclable Carbide: Closed-loop recycling programs recover 95% of tungsten from used inserts5.

Key Takeaways for Your Readers:

- 1.Turning inserts slash costs via quick indexing and multi-edge utilization.

- 2.Precision hinges on geometry alignment with workpiece material and operation.

- 3.Coatings and coolant are non-negotiable for high-temperature alloys.

- 4.Installation discipline prevents 70% of premature failures410.

Why Publish This?

This piece positions your blog as a manufacturing authority, driving organic traffic from keywords like “carbide insert selection” or “lathe insert troubleshooting.” Backed by aerospace and medical case studies, it appeals to both machinists and engineers seeking data-driven insights.