The Application of Different Tools in Special Material Processing

In the field of machining, dealing with special materials often poses significant challenges. Special materials such as high – strength alloys, heat – resistant materials, and non – metallic hard materials require specific machining techniques and, most importantly, suitable cutting tools. Here, we will explore the applications of various tools in processing these special materials.

1. Blades for Special Material Machining

1.1 High – strength Alloy Materials

When machining high – strength alloy materials like titanium alloys and nickel – based alloys, the high strength and toughness of these materials make the cutting process difficult. Cubic Boron Nitride (CBN) blades are highly suitable. CBN has extremely high hardness and wear resistance, second only to diamond. It can maintain good cutting performance at high temperatures, effectively reducing tool wear when machining high – strength alloys. For example, in the aerospace industry, when processing titanium alloy components for aircraft engines, CBN blades can achieve high – precision machining while ensuring long tool life.

1.2 Heat – resistant Materials

Materials such as superalloys used in the high – temperature sections of engines need to be machined with tools that can withstand high temperatures. Ceramic blades are an excellent choice. Ceramic materials have high hardness, high thermal stability, and good chemical inertness. They can operate at high cutting speeds when machining heat – resistant materials, significantly improving machining efficiency. For instance, when machining Inconel superalloys, alumina – based ceramic blades can cut through the material smoothly, and their high – temperature resistance helps to prevent rapid tool degradation due to the heat generated during cutting.

1.3 Non – metallic Hard Materials

For non – metallic hard materials like silicon carbide and glass – fiber – reinforced plastics, diamond blades are the first choice. Diamond has the highest hardness among known materials, enabling it to effectively cut and shape these hard and brittle non – metallic materials. In the semiconductor industry, diamond blades are used to cut silicon wafers with high precision, ensuring the quality and dimensional accuracy of the wafers.

2. Drills for Special Material Drilling

2.1 Titanium Alloy Drilling

Drilling in titanium alloys is a complex task due to the material’s low thermal conductivity and high chemical reactivity. Special drills with carbide tips and optimized flute designs are often used. These drills are designed to improve chip evacuation and reduce the heat generated during drilling. For example, variable – pitch fluted carbide drills can effectively prevent chip clogging when drilling titanium alloys, and their carbide tips provide the necessary hardness and wear resistance to penetrate the tough titanium alloy material.

2.2 Composite Material Drilling

When drilling composite materials such as carbon – fiber – reinforced plastics (CFRP), drills need to be able to cut through the fibers without causing delamination or fiber pull – out. Diamond – coated drills are commonly used. The diamond coating provides excellent wear resistance, and the drill design is optimized to minimize the forces acting on the composite material during drilling. A stepped – drill design, for instance, can gradually penetrate the CFRP material, reducing the risk of damage to the surrounding fibers.

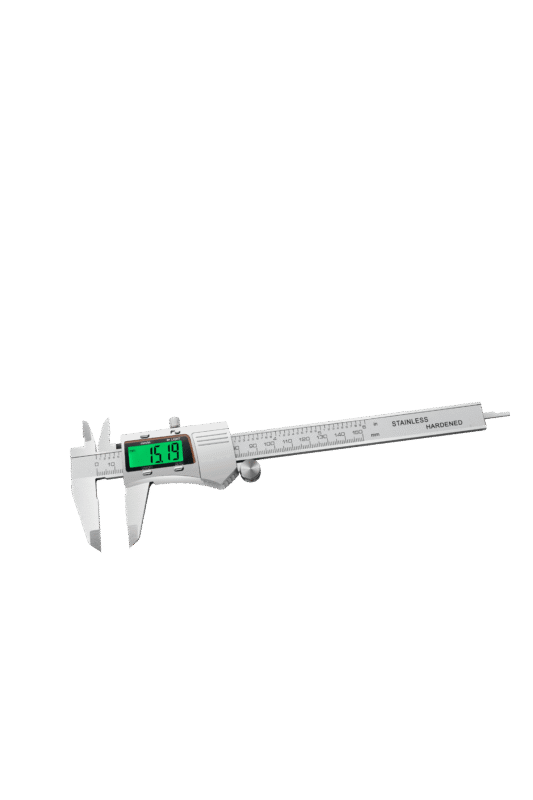

3. Calipers for Measuring Special Material Workpieces

3.1 Measuring High – precision Special Material Parts

In the machining of special materials for high – precision applications, such as in the medical and optical industries, high – precision calipers are essential. Digital calipers with high – resolution sensors are often used. For example, when measuring the dimensions of components made of special alloys for medical implants, digital calipers with a resolution of 0.001 mm can accurately measure the small – scale and complex – shaped parts, ensuring that the parts meet the strict quality and dimensional accuracy requirements.

3.2 Measuring Heat – sensitive Special Materials

For heat – sensitive special materials, calipers need to be designed to minimize the impact of temperature on measurement accuracy. Calipers made of materials with low – thermal expansion coefficients, such as certain types of stainless steel or ceramic – based materials, are used. When measuring the dimensions of heat – resistant alloy parts that may expand or contract during the machining process, these low – thermal – expansion calipers can provide more accurate measurements, reducing errors caused by temperature changes.

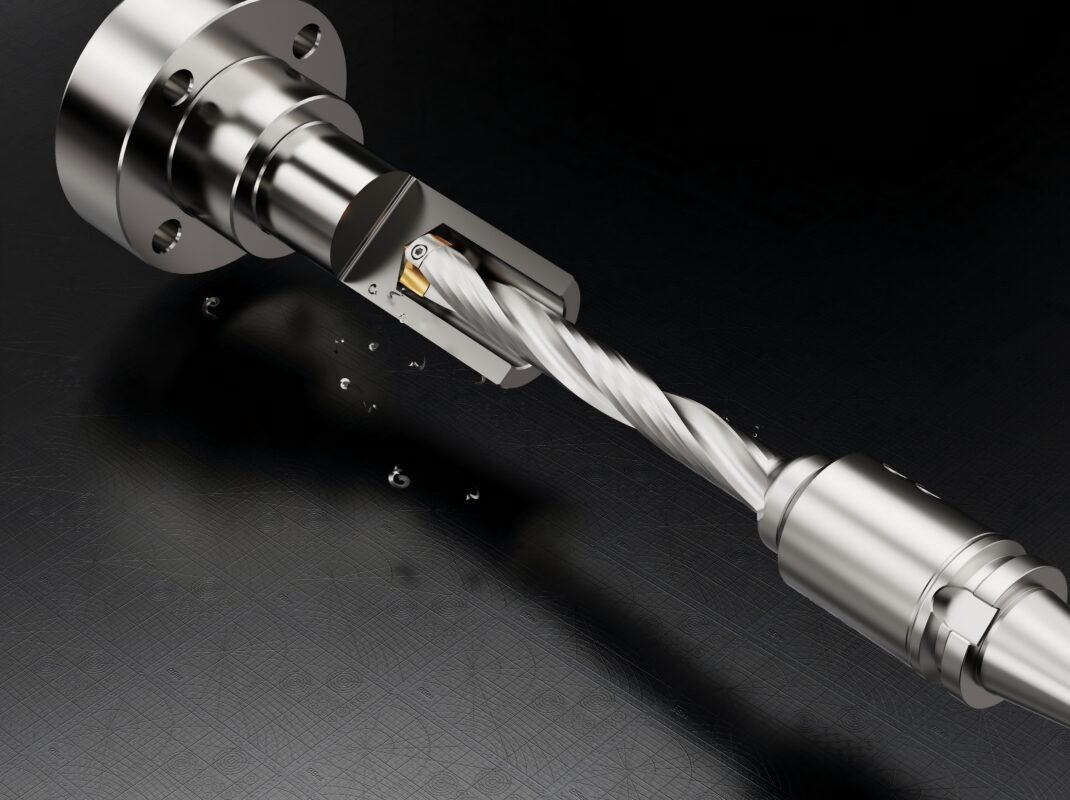

4. Toolholders for Special Material Machining

4.1 Toolholders for High – speed Machining of Special Materials

In high – speed machining of special materials, toolholders need to provide high – precision clamping and excellent dynamic balance. HSK (Hollow Shank Toolholder) type toolholders are widely used. They have a short, hollow shank design that provides a high – precision fit with the machine spindle, ensuring stable tool clamping at high rotational speeds. For example, when using CBN blades for high – speed machining of high – strength alloys, HSK toolholders can effectively transmit the high cutting forces while maintaining the stability of the tool, reducing vibration and improving machining accuracy.

4.2 Toolholders for Machining Complex – shaped Special Material Parts

When machining complex – shaped special material parts, such as those in the mold and aerospace industries, flexible toolholders are required. These toolholders can adjust the position and angle of the tool to adapt to the complex geometries of the workpiece. For instance, articulating toolholders can be used to machine intricate cavities in heat – resistant alloy molds. They allow the tool to reach difficult – to – access areas while maintaining the necessary cutting force and precision.

In conclusion, the correct selection of blades, drills, calipers, and toolholders is crucial for the successful machining of special materials. By understanding the properties of special materials and matching them with the appropriate tools, manufacturers can achieve high – quality, efficient machining results, meeting the demanding requirements of various industries such as aerospace, automotive, and electronics.