Step Drill Bits (Tapered Drill Bits): The Ultimate Guide to Drilling Multiple Hole Sizes with One Tool

In the world of hardware and DIY, few tools blend convenience and precision like step drill bits—often called “tapered drill bits” or “宝塔钻” (pagoda drill bits) for their stacked, tiered design. Unlike standard drill bits (which only create one hole size per bit), step drills feature a series of graduated “steps” that let you drill multiple hole diameters (e.g., 4mm, 6mm, 8mm) with a single tool. Whether you’re cutting holes in sheet metal for electrical boxes, enlarging existing holes in plastic, or working on thin aluminum projects, step drills eliminate the hassle of switching between bits—and reduce the risk of broken tools or uneven holes.

This guide breaks down everything you need to know about step drill bits: how they work, what materials they’re best for, pro tips for safe use, and how to choose the right one for your project. By the end, you’ll understand why step drills are a must-have for anyone working with thin materials.

What Are Step Drill Bits, and Why Are They Useful?

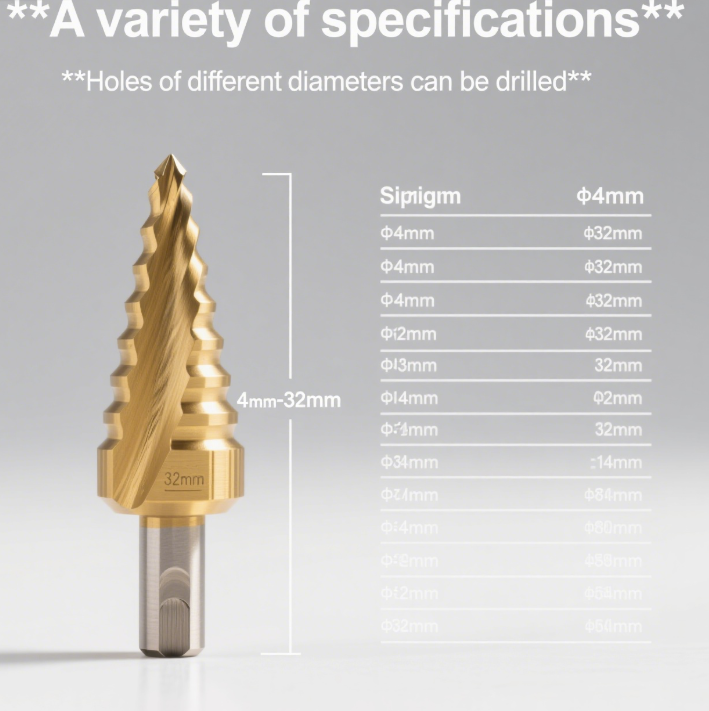

A step drill bit is a specialized drill bit with a conical or cylindrical shape, featuring 2–10+ concentric steps (each step represents a specific hole diameter). Each step has a sharp cutting edge, and the bit tapers slightly between steps to ensure smooth transitions when enlarging holes.

Key Benefits of Step Drill Bits

- One Bit, Multiple Sizes: No more fumbling with a set of 5+ standard bits—one step drill can handle 4–8 hole sizes (e.g., a 4–12mm step drill covers 4mm, 6mm, 8mm, 10mm, 12mm).

- Clean, Burr-Free Holes: Step drills cut with a shearing action (instead of the chipping action of standard bits), which leaves smooth edges—critical for sheet metal, plastic, or acrylic (where burrs are hard to sand off).

- No Pilot Hole Needed: Their pointed tip and gradual steps let you start drilling directly into the material (unlike large standard bits, which often require a small pilot hole to avoid “walking”).

- Ideal for Thin Materials: Designed for sheet metal (0.5–3mm thick), thin aluminum, plastic, or acrylic—standard bits can warp or crack these materials, but step drills distribute pressure evenly.

How They Compare to Standard Drill Bits

| Feature | Step Drill Bits | Standard Drill Bits |

|---|---|---|

| Hole Sizes per Bit | 4–8 sizes (graduated steps) | 1 size per bit |

| Pilot Hole Required | No | Often yes (for sizes >8mm) |

| Burrs After Drilling | Minimal (clean edges) | Common (needs deburring) |

| Best for Materials | Thin metal, plastic, acrylic | Thick wood, metal, concrete |

| Risk of Walking | Low (pointed tip + wide base) | High (especially for large bits) |

Types of Step Drill Bits (By Material & Design)

Not all step drill bits are the same—they’re categorized by the materials they’re made from (which dictates durability) and their design (which affects use case). Here’s how to choose:

1. By Material: HSS vs. HSS-Co vs. Carbide

The material of the step drill determines its ability to cut hard materials and resist wear:

| Material | Hardness (HRC) | Best For | Lifespan (vs. HSS) | Price (Relative) |

|---|---|---|---|---|

| High-Speed Steel (HSS) | 62–64 | Thin mild steel (<1mm), plastic, wood | 1x (base level) | $ (Budget) |

| HSS-Cobalt (HSS-Co) | 65–67 | Thin stainless steel (1–2mm), aluminum | 3x | $$ (Mid-Range) |

| Carbide-Tipped | 85–90 | Thick stainless steel (2–3mm), titanium | 10x | $$$ (Premium) |

Real-World Example: If you’re drilling 100 holes in 1mm thick 304 stainless steel:

- An HSS step drill will dull after 15–20 holes.

- An HSS-Co step drill will finish 40–50 holes.

- A carbide-tipped step drill will handle 150+ holes.

2. By Design: Straight-Flute vs. Spiral-Flute

The flute design affects chip removal and cutting smoothness:

- Straight-Flute Step Drills: Simple design with straight grooves for chip evacuation. Best for plastic, acrylic, or thin mild steel—chips fall out easily, and they’re affordable.

- Spiral-Flute Step Drills: Flutes twist upward (like a standard drill bit), which pulls chips out of the hole more efficiently. Ideal for stainless steel or aluminum—prevents chip clogging (which causes overheating).

3. Specialized Step Drills

- Hex-Shank Step Drills: Have a hexagonal shank (instead of round) that fits securely in drill chucks—no slipping, even at high speeds. Great for cordless drills.

- Double-Ended Step Drills: Feature steps on both ends (e.g., 4–12mm on one end, 14–20mm on the other)—saves space in your toolbox.

- Unibit® (Branded Step Drills): A popular brand of spiral-flute step drills known for durability—often used by electricians and HVAC technicians.

What Materials Can You Drill with Step Drill Bits?

Step drills excel at cutting thin, soft-to-medium-hard materials—they’re not designed for thick wood, concrete, or stone (use standard bits or masonry bits for those). Here’s a breakdown of their best uses:

1. Sheet Metal (0.5–3mm Thick)

- Use Case: Drilling holes for electrical outlets, HVAC ducts, or metal brackets.

- Pro Tip: Use an HSS-Co or carbide step drill (stainless steel sheet metal is abrasive). Keep the drill speed slow (500–1,000 RPM) to avoid overheating.

2. Aluminum (Thin Sheets or Extrusions)

- Use Case: Building custom aluminum frames, bike parts, or electronics enclosures.

- Pro Tip: Spiral-flute step drills work best—they pull aluminum chips out of the hole (aluminum chips are sticky and can clog straight flutes).

3. Plastic & Acrylic

- Use Case: Cutting holes in plastic storage bins, acrylic signs, or 3D printed parts.

- Pro Tip: Use a straight-flute HSS step drill at medium speed (1,000–1,500 RPM). Too fast, and plastic melts; too slow, and it cracks.

4. Thin Copper & Brass

- Use Case: Plumbing projects (drilling holes in copper pipes) or jewelry making (brass sheets).

- Pro Tip: Apply light cutting oil to reduce friction—copper and brass are soft but can gum up the drill’s cutting edges.

Materials to Avoid

- Thick Metal (>3mm): Step drills will overheat and dull—use a standard twist drill bit instead.

- Hardwood: Step drills can splinter wood (they’re designed for shearing, not chipping).

- Concrete/Stone: Step drills have no abrasive cutting edges—use a masonry bit with a hammer drill.

How to Use Step Drill Bits Correctly (Avoid Common Mistakes)

Using a step drill bit is simple—but a few missteps can ruin the bit or the material. Follow these steps for perfect holes every time:

1. Prepare Your Drill & Material

- Choose the Right Drill: Use a corded or cordless drill with variable speed (step drills need slow-to-medium speeds). Avoid hammer drills—hammering will chip the bit’s cutting edges.

- Secure the Material: Clamp thin metal, plastic, or acrylic to a workbench—never hold it by hand (it can spin or flex, causing uneven holes). For sheet metal, place a piece of wood under it (prevents the material from warping).

- Select the Correct Step Drill: Match the bit to your material (e.g., HSS-Co for stainless steel) and the largest hole size you need (e.g., a 4–12mm bit for holes up to 12mm).

2. Set the Speed

Speed is critical—too fast, and the bit overheats; too slow, and it takes too long. Use this guide:

| Material | Thickness | Drill Speed (RPM) |

|---|---|---|

| Mild Steel | 0.5–1mm | 800–1,000 |

| Stainless Steel | 1–2mm | 500–800 |

| Aluminum | 1–3mm | 1,000–1,500 |

| Plastic/Acrylic | 2–5mm | 1,200–1,800 |

3. Drill the Hole

- Start Slowly: Position the bit’s tip on your mark, then start the drill at low speed. Let the tip bite into the material (this prevents walking).

- Progress Through Steps: Once the first step (smallest size) cuts through, continue applying light pressure— the bit will naturally move to the next step. Don’t force it—let the cutting edges do the work.

- Clear Chips: For metal or aluminum, pause every 1–2 steps to blow out chips (use compressed air or a brush). Clogged chips cause overheating.

4. Finish Cleanly

- Exit Slowly: When the final step cuts through, reduce speed slightly to avoid burring the back of the material.

- Deburr (If Needed): For metal, use a deburring tool or sandpaper to smooth any small burrs (step drills minimize burrs, but thin steel may still have minor edges).

Common Mistakes to Avoid

- Forcing the Bit: Pushing too hard bends the bit or warps the material—light pressure is all you need.

- Using the Wrong Speed: Drilling stainless steel at 2,000 RPM will dull the bit in seconds.

- Skipping Clamping: Unsecured material spins, leading to uneven holes or injury.

- Drilling Thick Material: Step drills are for thin materials—drilling 5mm steel will overheat the bit.

Maintenance: Extend Your Step Drill Bit’s Life

A quality step drill bit can last for years with proper care. Follow these tips to keep it sharp and functional:

1. Clean After Every Use

- Wipe the bit with a lint-free cloth to remove chips and cutting oil. For sticky aluminum chips, use a wire brush (soft brass brush—steel brushes scratch the cutting edges).

- For plastic residue (common with acrylic), wipe the bit with rubbing alcohol—this dissolves the plastic without damaging the metal.

2. Sharpen Dull Bits

- HSS/HSS-Co Bits: Use a diamond file to sharpen the cutting edges of each step. Hold the file at a 30° angle (matching the original edge) and make 2–3 light strokes per edge. Avoid over-sharpening—this reduces the bit’s lifespan.

- Carbide-Tipped Bits: Don’t sharpen them at home—carbide is too hard, and improper sharpening will ruin the tip. Take them to a professional sharpener or replace them when dull.

3. Store Properly

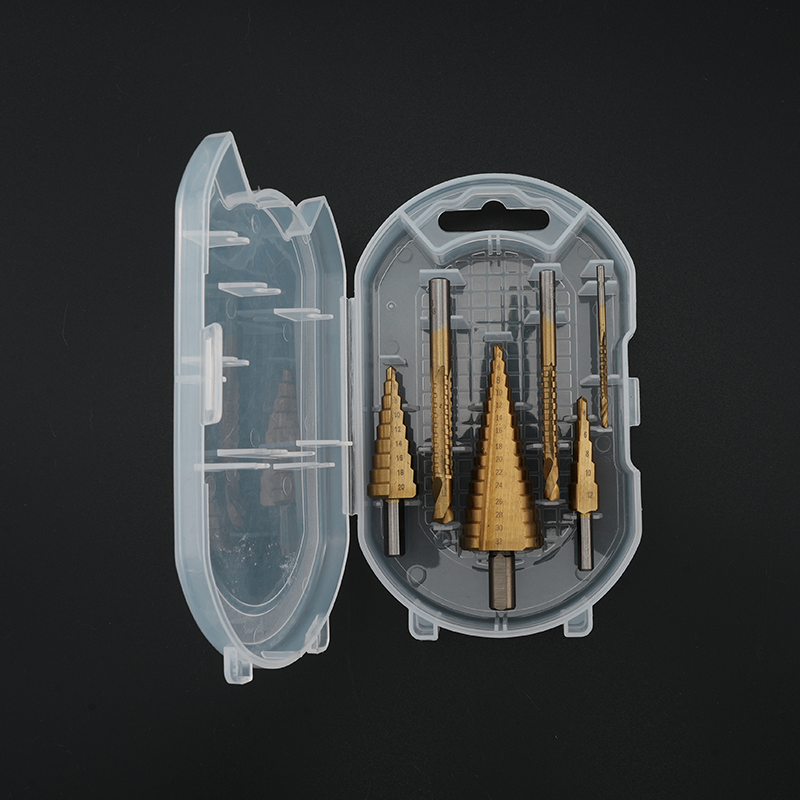

- Keep step drills in a dedicated case (many come with labeled slots) or a drill bit organizer. Avoid tossing them in a toolbox—they can collide with other tools and chip.

- For HSS bits, apply a light coat of machine oil before storing (prevents rust in humid workshops). Carbide bits don’t need oil—store them in a dry place.

4. Know When to Replace

Replace your step drill bit if:

- The cutting edges are chipped or rounded (visible to the naked eye).

- It takes 2x longer to drill a hole (sign of dulling).

- It leaves rough, burred edges (even after deburring).

Final Thoughts: Are Step Drill Bits Worth the Investment?

If you regularly work with thin materials (sheet metal, plastic, aluminum), the answer is a resounding “yes.” A $20–$50 HSS-Co step drill will replace a $10 set of standard bits, save time switching between tools, and produce cleaner holes. For professionals (electricians, HVAC techs, metalworkers), a premium carbide-tipped step drill is even more valuable—it handles tough stainless steel and lasts for hundreds of holes.

Remember: The key to getting the most out of your step drill is matching it to your material, using the right speed, and maintaining it properly. With these steps, your step drill will become one of your most-used tools—turning tedious hole-drilling into a quick, easy task.

Now grab your step drill, clamp your material, and start drilling—clean, precise holes are just a few steps away!