Saw Blades in Machining: Materials, Techniques, and Machinable Workpieces

Saw blades are essential cutting tools in mechanical machining, designed to slice through materials with precision and efficiency. From metal alloys to composites, their performance depends on material composition, tooth design, and proper usage. This blog explores the key aspects of saw blades, helping you select the right tool for your application and achieve optimal results.

Saw Blade Materials: The Foundation of Cutting Performance

The material of a saw blade determines its hardness, wear resistance, and ability to withstand heat—critical factors for clean, efficient cuts. Here are the most common materials:

High-Speed Steel (HSS)

HSS saw blades are alloyed with tungsten, molybdenum, and chromium, offering a balance of toughness and affordability. Key traits include:

- Ductility: Resists chipping during interrupted cuts, making them ideal for general-purpose machining.

- Heat resistance up to 600°C: Suitable for low-to-medium speed cutting (10–50 m/min) of mild steel, aluminum, and brass.

- Re-sharpenability: Can be sharpened multiple times, extending their lifespan for small-batch production.

HSS blades are often coated with TiN (titanium nitride) to reduce friction and wear, enhancing performance on non-ferrous metals.

Carbide-Tipped

Carbide-tipped blades feature tungsten carbide teeth brazed to a steel alloy body. They excel in:

- High-speed cutting: Withstand temperatures up to 1,000°C, allowing speeds of 50–200 m/min on steel and cast iron.

- Wear resistance: Last 5–10x longer than HSS blades when machining abrasive materials like cast iron or fiberglass.

- Precision cuts: Maintain sharp edges for consistent kerf width (the width of the cut), critical for tight-tolerance parts.

They are the go-to choice for mass production and heavy-duty applications.

Diamond-Coated

Diamond-coated blades use synthetic diamond particles bonded to the cutting edge, designed for ultra-hard materials:

- Extreme hardness: Cut through ceramics, glass, carbon fiber composites, and hardened steel (50+ HRC) with minimal wear.

- Cool cutting action: Generate less heat than carbide, reducing the risk of thermal damage to sensitive materials.

These blades are costly but indispensable for specialized industries like aerospace and electronics.

Tooth Design: Matching Geometry to Material

Beyond material, tooth geometry dictates a blade’s performance. Key parameters include:

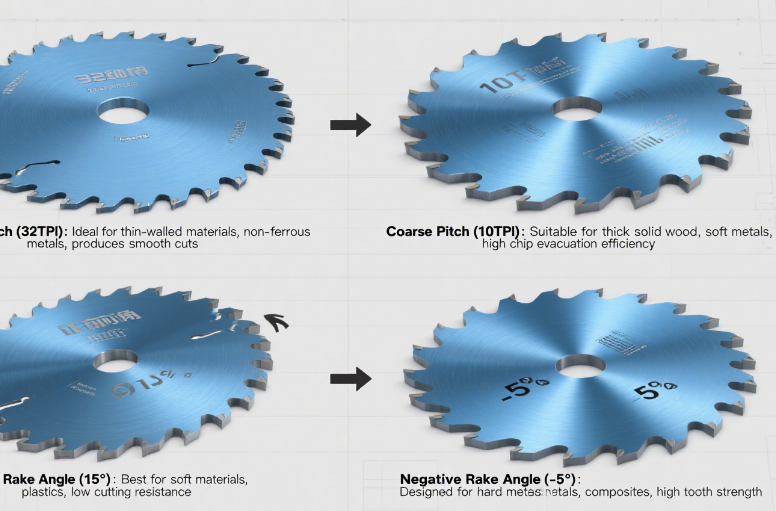

- Tooth Pitch: The distance between adjacent teeth. Fine pitch (1–2 mm) works best for thin materials (e.g., sheet metal) to prevent tooth overload; coarse pitch (3–6 mm) handles thick stock (e.g., steel bars) by clearing chips efficiently.

- Tooth Angle: Positive rake angles (10°–20°) reduce cutting force, ideal for aluminum and plastics; negative rake angles (0°–-10°) add strength, suited for hardened steel and cast iron.

- Gullet Size: The space between teeth. Larger gullets accommodate bigger chips, critical for rough cutting in cast iron.

Usage Methods: Best Practices for Saw Blades

Proper technique ensures clean cuts, long blade life, and operator safety:

Speed and Feed Rate

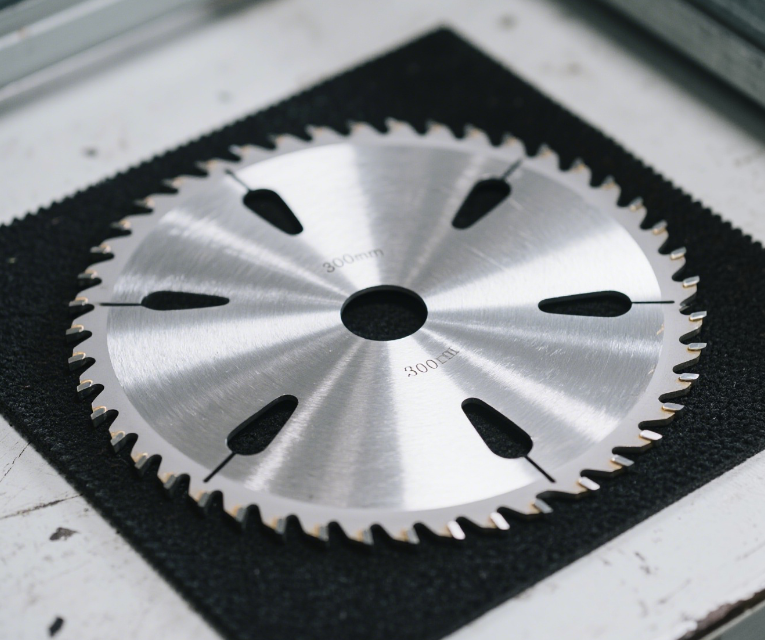

- Circular saws: Adjust RPM based on blade diameter and material. For example, a 300mm carbide-tipped blade cuts steel at 1,000–1,500 RPM; HSS blades require 500–800 RPM for the same material.

- Band saws: Control feed rate (mm/min) to match material thickness. Too fast causes blade dulling; too slow leads to overheating.

Coolant Application

- Flood cooling: For HSS and carbide blades cutting steel, to reduce heat and flush chips from the kerf.

- Mist cooling: For high-speed carbide cutting, combining coolant and air to improve heat transfer without excessive fluid usage.

- Dry cutting: Only suitable for diamond-coated blades on non-ferrous materials (e.g., aluminum) to avoid coolant contamination.

Blade Maintenance

- Cleaning: Remove pitch, chips, and debris with a wire brush after use—buildup causes uneven wear.

- Sharpening: HSS blades can be sharpened with a grinding wheel; carbide-tipped blades require specialized diamond grinding.

- Storage: Hang blades vertically or store in protective cases to prevent warping or tooth damage.

Machinable Materials: Matching Blades to Workpieces

Saw blades are tailored to specific materials, ensuring efficiency and precision:

Metals

- Mild Steel (1018): HSS or carbide-tipped blades with positive rake angles. Use coolant to prevent discoloration.

- Stainless Steel (304): Carbide-tipped blades with negative rake angles and coolant—resists work-hardening.

- Aluminum (6061): HSS blades with TiN coating or diamond-coated blades for high-speed, burr-free cuts.

- Cast Iron (GG25): Carbide-tipped blades with coarse pitch to handle abrasive chips.

Non-Metals

- Plastics (PVC, ABS): HSS blades with fine pitch to avoid melting; use low speed and coolant.

- Composites (Fiberglass, Carbon Fiber): Diamond-coated blades to cut through reinforcing fibers without fraying.

- Ceramics (Alumina): Diamond-coated blades with slow feed rates to prevent cracking.

Specialized Saw Blades: Beyond General Machining

Advanced applications demand specialized designs:

- TCT (Tungsten Carbide Tipped) Blades: For cutting structural steel and tubing with minimal burrs.

- Abrasive Blades: Reinforced with aluminum oxide for cutting concrete or masonry (used in construction machining).

- Slitting Saws: Thin, circular blades for precision slotting in metal sheets, often used in automotive part production.

Conclusion

Saw blades are versatile tools that bridge material and machine, with their performance shaped by material, tooth design, and usage. Whether using HSS for general metalwork, carbide for high-volume steel cutting, or diamond for composites, selecting the right blade and applying proper techniques ensures efficiency, precision, and longevity.

In machining, where every cut counts, the saw blade is more than a tool—it’s a precision instrument that defines the quality of the final product.