Milling Cutters: Essential Tools in Metal Machining

Milling cutters are vital tools in metal machining, designed to remove material from workpieces through rotary motion. They come in a variety of types, each tailored to specific machining tasks, ensuring efficiency and precision in diverse applications.

1. Types of Milling Cutters by Structure

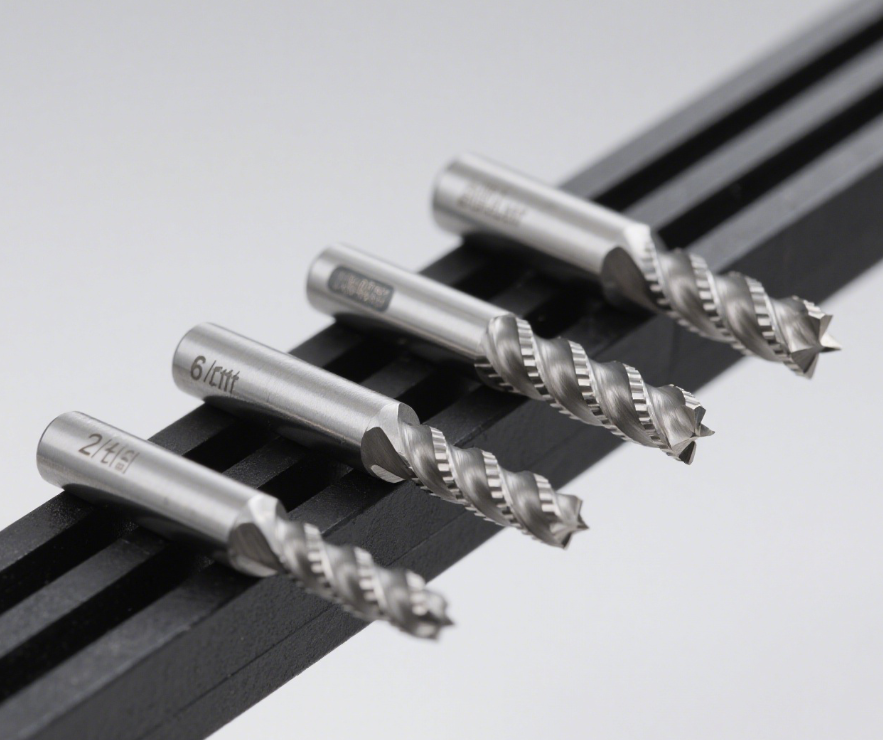

1.1 Solid Carbide Milling Cutters

Solid carbide milling cutters are made entirely of carbide, a material known for its high hardness and wear resistance. This makes them ideal for high-speed machining and processing hard materials such as alloy steels and cast irons. They have a one-piece construction, providing excellent rigidity and ensuring stable cutting performance.

These cutters are available in various flutes, with 2-flute, 4-flute, and 6-flute designs being common. 2-flute cutters are suitable for slotting and roughing operations, as they allow for better chip evacuation. 4-flute cutters, on the other hand, are often used for finishing, delivering a smoother surface finish due to their more frequent cutting action.

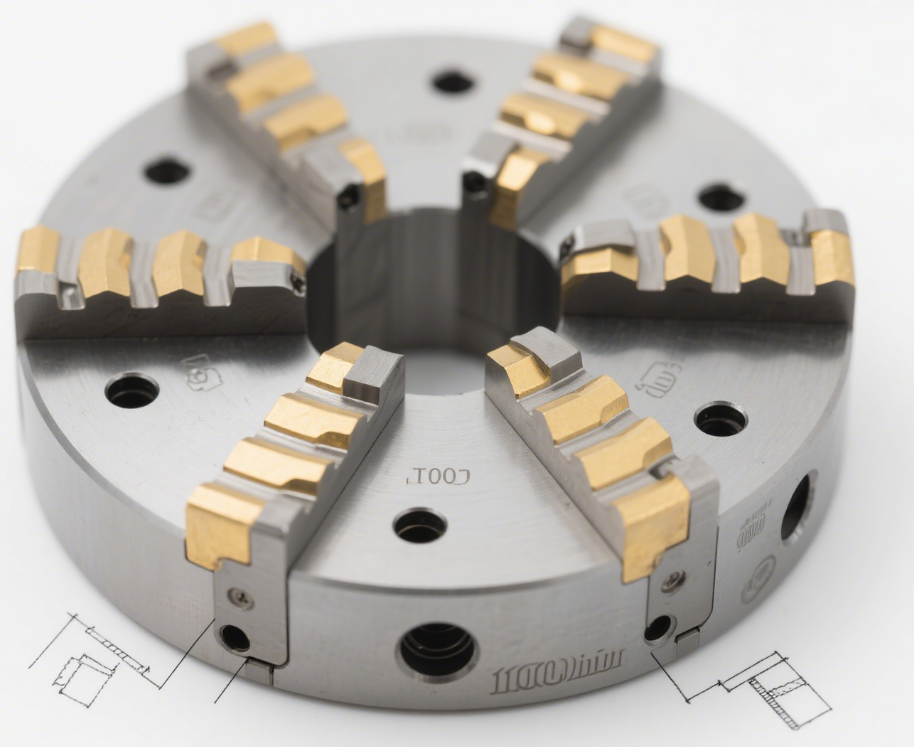

1.2 Indexable Milling Cutters

Indexable milling cutters feature replaceable carbide inserts that are mounted on a steel body. When the inserts become dull, they can be easily replaced with new ones, reducing tool change time and maintenance costs. This design is highly cost-effective for large-scale production.

Common types of indexable milling cutters include face mills, shoulder mills, and end mills. Face mills are used for machining flat surfaces, with inserts arranged on the cutter’s face to cover a large area. Shoulder mills are designed to machine shoulders and steps, providing precise 90-degree angles.

2. Key Features Affecting Performance

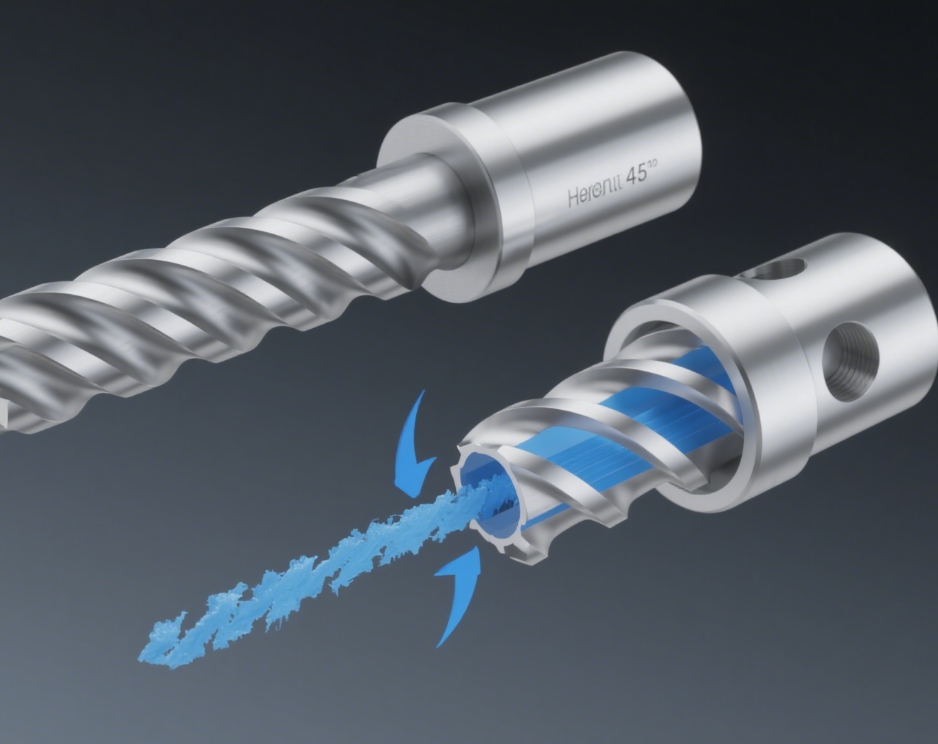

2.1 Flute Design

The flute design of a milling cutter plays a crucial role in chip evacuation and cutting efficiency. Straight flutes are simple and suitable for low-speed machining, while helical flutes provide better chip flow and reduce cutting forces, making them ideal for high-speed and heavy-duty operations.

The helix angle is another important parameter. A higher helix angle (e.g., 45 degrees) allows for smoother cutting and better surface finish, while a lower helix angle (e.g., 30 degrees) provides more rigidity, suitable for roughing.

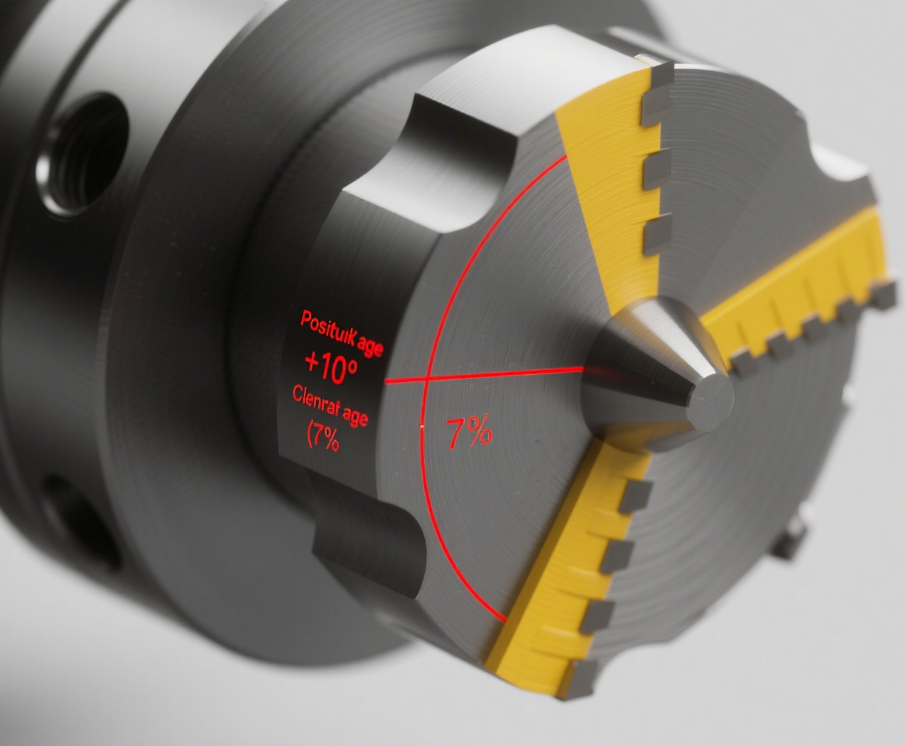

2.2 Cutting Edge Geometry

The cutting edge geometry, including rake angle and clearance angle, affects the cutting force, tool life, and surface quality. A positive rake angle reduces cutting forces, making it suitable for machining soft materials like aluminum. A negative rake angle provides more strength to the cutting edge, ideal for hard materials and heavy cutting.

The clearance angle prevents the cutter’s flank from rubbing against the workpiece, reducing wear. Proper clearance angles ensure smooth cutting and extend tool life.

3. Applications in Various Machining Tasks

3.1 Roughing Operations

For roughing, where large amounts of material need to be removed quickly, coarse-pitch milling cutters with fewer flutes are preferred. They allow for efficient chip evacuation, preventing chip clogging. Solid carbide 2-flute end mills or indexable roughing mills are commonly used in this scenario.

In the automotive industry, roughing operations are performed on engine blocks to remove excess material before finishing. The use of high-performance roughing mills ensures that the process is completed efficiently.

3.2 Finishing Operations

Finishing requires a smooth surface finish and tight dimensional tolerances. Fine-pitch milling cutters with more flutes are used, as they provide more cutting edges and reduce surface roughness. 4-flute or 6-flute solid carbide end mills with a high helix angle are typical choices.

In mold making, finishing operations on cavity surfaces demand high precision. Milling cutters with sharp cutting edges and optimized flute designs are used to achieve the required surface quality, which is crucial for the mold’s functionality.

4. Matching with Machine Tools and Workpiece Materials

Selecting the right milling cutter requires considering the machine tool’s capabilities and the workpiece material. High-speed machining centers require milling cutters with good dynamic balance and high rigidity, such as solid carbide cutters with short overhangs.

For aluminum machining, milling cutters with polished flutes and positive rake angles are used to prevent built-up edge. For stainless steel, which is tough and work-hardening, cutters with high wear resistance, such as those coated with TiAlN, are preferred.

Milling cutters, with their diverse types and features, are indispensable in metal machining. By understanding their characteristics and applications, manufacturers can select the most suitable cutter for each task, ensuring efficient and high-quality production.