Measuring Tools in Hardware: A Deep Dive into Diversity, Materials, and Precision

In hardware, woodworking, or metalworking, measuring tools are the difference between a “good enough” project and a precision masterpiece. But not all measuring tools are created equal—their performance, durability, and use cases depend on two critical factors: tool type (what they measure) and material (what they’re made of).

This blog breaks down the most essential measuring tools, explores how materials like stainless steel, aluminum, and tool steel impact their functionality, and shares pro tips to help you choose, use, and maintain your 量具 (measuring tools) for years. No fluff—just data-driven insights and practical advice.

1. The Diversity of Measuring Tools: What They Do & When to Use Them

Measuring tools are categorized by the dimensions they measure. Each type is engineered for specific tasks, and their materials are tailored to match their workload.

a. Linear Measuring Tools: For Length, Thickness, and Diameter

Linear tools measure straight dimensions (e.g., “how thick is this metal sheet?” or “what’s the diameter of this bolt?”). They’re the most versatile 量具 in any workshop.

i. Digital Calipers

- Function: Measures external (OD), internal (ID), and depth dimensions with 0.01mm accuracy (far more precise than rulers).

- Common Materials:

- Stainless Steel (304): Most durable option—resists rust, scratches, and deformation. Ideal for metalworking (exposed to oil/coolant).

- Carbon Steel (with Chrome Plating): Cheaper than stainless steel but prone to rust if not oiled. Good for occasional DIY use.

- Plastic (ABS): Lightweight and affordable (under $15) but less precise (±0.05mm) and easily damaged. Best for hobby woodworking (no heavy wear).

- Best For: Small parts (screws, washers), precision metal fabrication, and checking hole sizes.

ii. Outside Micrometers

- Function: Ultra-precise measurements (0.001mm accuracy) for thin materials (e.g., foil) or small diameters (e.g., needle shafts).

- Key Material: Tool Steel (HSS, Hardness 60–62 HRC) for the “anvil” (fixed end) and “spindle” (moving end)—hard enough to avoid indentations from metal parts. The frame is often cast iron (stable, minimizes vibration).

- Pro Tip: Avoid dropping micrometers—tool steel spindles chip easily, ruining precision.

iii. Tape Measures

- Function: Measures large dimensions (1–10m) for construction, furniture building, or layout work.

- Materials:

- Blade: Carbon steel (flexible, durable) or fiberglass (rust-proof, ideal for outdoor use).

- Case: ABS plastic (lightweight, cheap) or rubberized plastic (shock-resistant, for job sites).

- Feature to Look For: “Double-sided markings” (mm on one side, inches on the other) and a “lock” to hold the blade in place.

b. Angle Measuring Tools: For Perfect 90°, 45°, and Custom Angles

Angles are critical for joinery (e.g., a 45° miter cut for a picture frame) or machinery alignment. Angle tools’ materials prioritize rigidity (to avoid bending) and accuracy.

i. Speed Square

- Function: Marks 90° (right angles), 45° (miters), and 30°/60° angles—doubles as a straightedge for cutting lines.

- Materials:

- Aluminum Alloy (6061): Lightweight (easy to carry) and rigid (no bending). Anodized finish resists scratches. Perfect for DIY and carpentry.

- Steel: Heavier but more durable—used for industrial metalworking (exposed to heavy impacts).

- Price Range: 5(aluminum)vs.20 (steel)—aluminum is best for most users.

ii. Digital Protractor

- Function: Measures angles (0–180°) with 0.1° accuracy—displays readings on an LCD screen (no manual interpretation errors).

- Materials:

- Base: Aluminum alloy (stable, minimizes temperature-induced warping).

- Sensor Housing: ABS plastic (protects internal electronics from dust).

- Best For: CNC machining, aerospace parts, or any project where angles need to be exact (e.g., a 120° angle on a metal bracket).

iii. Bevel Protractor

- Function: Measures irregular angles (e.g., the angle of a pipe or welded joint) with a adjustable blade.

- Material: Stainless Steel (blade) + cast iron (base)—rigid enough to hold angles without slipping, even under pressure.

c. Surface & Precision Measuring Tools: For Smoothness, Flatness, and Gaps

These tools check “invisible” flaws—like a warped metal plate or a tiny gap in a bearing—that ruin performance. Their materials prioritize precision and sensitivity.

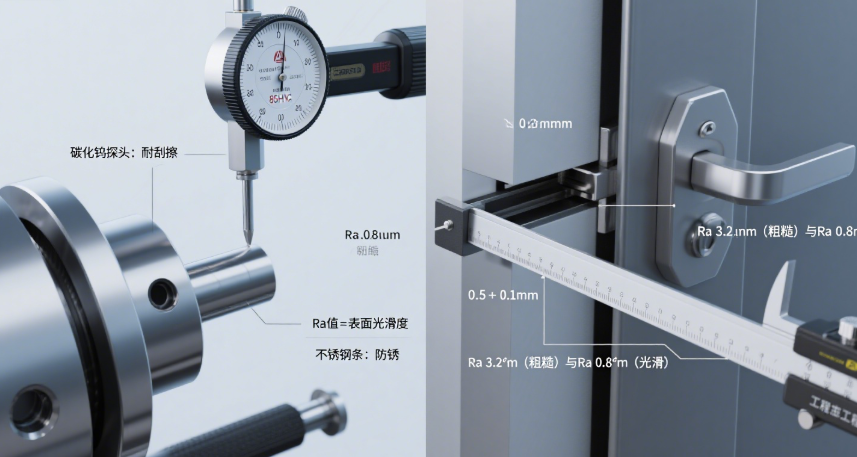

i. Dial Indicators

- Function: Measures tiny movements (0.01mm accuracy) to check “runout” (wobble in rotating parts) or flatness.

- Materials:

- Probe: Tungsten Carbide (hardness 85–90 HRC)—scratch-resistant, even on hardened steel.

- Body: Stainless Steel (resists oil/coolant in machine shops).

- Use Case: Checking if a CNC lathe’s spindle is aligned (runout >0.02mm causes uneven cuts).

ii. Surface Roughness Tester

- Function: Measures surface smoothness (Ra value, in μm)—e.g., Ra 0.8μm = smooth enough for painting; Ra 0.2μm = ultra-smooth for engine bearings.

- Material: Titanium-Coated Probe (wear-resistant) + Aluminum Body (lightweight for handheld use).

iii. Feeler Gauges

- Function: Measures small gaps (0.02–1mm) with thin metal strips—e.g., checking a door hinge gap or bearing “play.”

- Material: Stainless Steel (strips)—thin but strong (no bending), and rust-proof (critical for tight gaps where moisture collects).

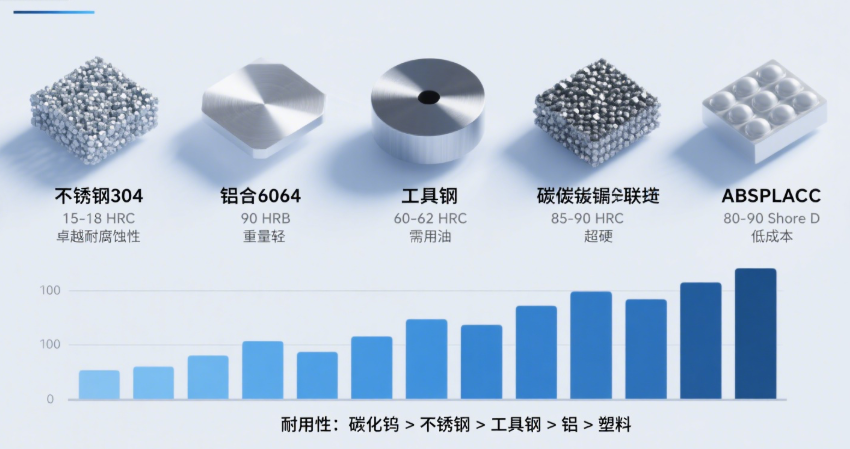

2. Material Showdown: Which Measuring Tool Material Is Best?

The material of your measuring tool directly impacts its durability, accuracy, and cost. Below is a side-by-side comparison of the most common materials:

| Material | Hardness (HRC/Rockwell) | Corrosion Resistance | Weight (g/cm³) | Cost (Relative) | Best For Tools | Pros | Cons |

| Stainless Steel 304 | 15–18 HRC | Excellent (no rust) | 7.9 | Medium ($$) | Calipers, micrometer frames | Rust-proof, durable | Heavy, more expensive than aluminum |

| Aluminum Alloy 6061 | 90 HRB (≈10 HRC) | Good (anodized) | 2.7 | Low ($) | Speed squares, protractor bases | Lightweight, cheap | Less rigid than steel, scratches easily |

| Tool Steel (HSS) | 60–62 HRC | Poor (needs oil) | 7.8 | Medium ($$) | Micrometer spindles, blades | Ultra-hard, precise | Rusts without maintenance |

| Tungsten Carbide | 85–90 HRC | Excellent | 15.6 | High ($$$) | Dial indicator probes | Scratch-resistant, longest life | Very heavy, brittle (chips if dropped) |

| ABS Plastic | 80–90 Shore D | Good | 1.05 | Very Low ($) | Tape measure cases, cheap calipers | Lightweight, affordable | Low precision, easily damaged |

Key Takeaway: For heavy use (metalworking), choose stainless steel or tungsten carbide. For DIY/hobby use, aluminum or plastic balances cost and performance.

3. Pro Tips: Calibration, Maintenance, and Selection

Even the best measuring tools fail without proper care. Here’s how to maximize their life and accuracy:

a. Calibrate Regularly

- Why: Tools drift over time (e.g., a caliper’s jaws wear down, causing 0.02mm errors).

- How:

- Use gauge blocks (standardized metal blocks with known dimensions, e.g., 25.000mm) to check calipers/micrometers.

- For dial indicators, use a precision level to verify zero.

- Frequency: Industrial use (every 3 months); DIY use (every 12 months).

b. Maintain Based on Material

- Stainless Steel: Wipe with a dry cloth after use—no oil needed (rust-proof).

- Tool Steel: Oil moving parts (e.g., micrometer spindles) to prevent rust.

- Aluminum: Avoid abrasive cleaners (scratches ruin accuracy)—use a soft cloth and mild soap.

- Plastic: Keep away from heat (melts at 80°C) and sharp objects.

c. Choose the Right Tool for the Job

- DIY Woodworking: Aluminum speed square + fiberglass tape measure + plastic digital caliper ($50 total).

- Metalworking: Stainless steel caliper + tool steel micrometer + tungsten carbide dial indicator ($200 total).

- Industrial Precision: Tungsten carbide roughness tester + stainless steel bevel protractor ($500+ total).

50;Metalworking:200; Industrial: $500+.”]

Final Thought: Invest in the Right Material, Not Just the Tool

A measuring tool’s value isn’t just in its accuracy—it’s in how long it maintains that accuracy. For example:

- A $15 plastic caliper works for 6 months (DIY use).

- A $50 stainless steel caliper lasts 5+ years (metalworking use).

By understanding tool diversity and material strengths, you’ll avoid wasting money on cheap tools that fail, and instead invest in 量具 that grow with your projects.

Whether you’re building a shelf or manufacturing precision parts, remember: precision starts with the right material.