Mastering Precision: A Deep Dive into Measuring Tools in Hardware

In the world of hardware and metalworking, precision is the cornerstone of success. Measuring tools, or 量具 in Chinese, are the unsung heroes that ensure every cut, drill, and assembly is accurate. From the simplest calipers to the most advanced digital micrometers, these tools play a pivotal role in maintaining quality and consistency. This blog will explore the different types of measuring tools, their applications, and how to use them effectively.

1. Types of Measuring Tools

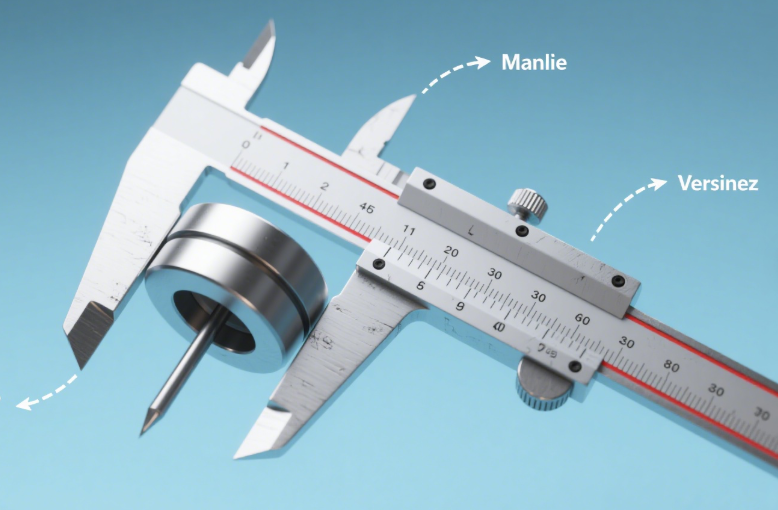

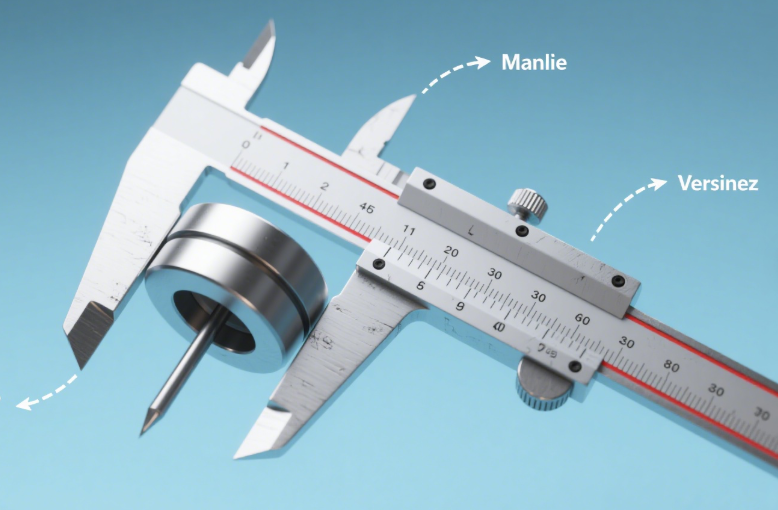

Vernier Calipers

Vernier calipers are a classic example of precision measuring tools. They consist of a main scale and a sliding vernier scale, allowing for measurements with an accuracy of up to 0.02 mm. These calipers are ideal for measuring the internal and external dimensions of objects, as well as depths.

How it Works: The vernier scale slides along the main scale. The alignment of the lines on both scales gives the precise measurement. For example, if the 5th line on the vernier scale aligns with a line on the main scale, and the main scale reads 25 mm, the total measurement is 25 + (5 × 0.02) = 25.10 mm.

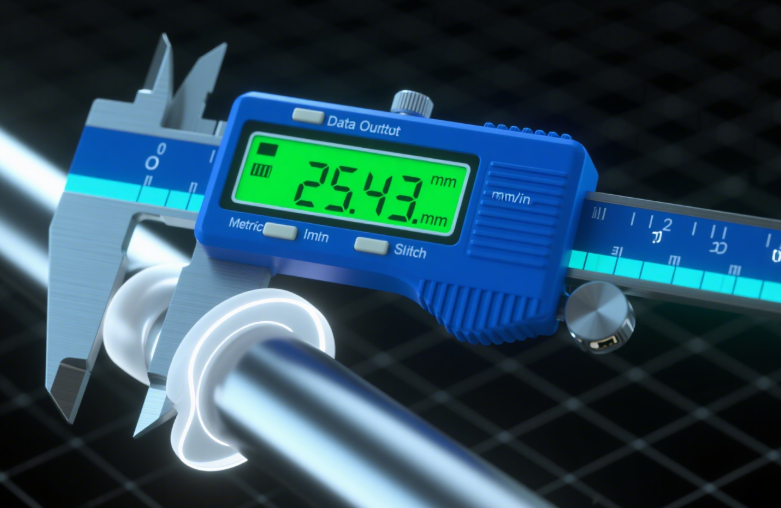

Digital Calipers

Digital calipers are a modern take on vernier calipers, featuring an electronic display for quick and easy reading. They offer high accuracy (up to 0.01 mm) and can switch between metric and imperial units.

Advantages:

- Instant readability, reducing human error in interpretation.

- Some models come with data output options, allowing for easy recording of measurements.

Micrometers

Micrometers, also known as micrometer screws, are used for extremely precise measurements, typically down to 0.01 mm or even 0.001 mm for high-precision models. They are commonly used in machining and engineering for measuring thin materials, wire diameters, and small distances.

Types:

- Outside Micrometer: For measuring external dimensions.

- Inside Micrometer: For measuring internal dimensions.

- Depth Micrometer: For measuring depths.

Dial Indicators

Dial indicators are used to measure small deviations in position or shape. They are often used in quality control to check for runout, flatness, and alignment. A dial indicator consists of a needle that moves over a dial, with each division representing a small measurement (e.g., 0.01 mm).

2. Applications of Measuring Tools

In Machining

In machining operations, measuring tools are used to ensure that parts are manufactured to precise specifications. For example, a micrometer is used to measure the diameter of a machined shaft, ensuring it meets the required tolerance.

In Quality Control

Quality control processes rely heavily on measuring tools to check the dimensions of finished products. Digital calipers can quickly verify if a batch of parts meets the design criteria, reducing the risk of defective products reaching the market.

In Assembly

During assembly, measuring tools help ensure that components fit together correctly. A vernier caliper can measure the internal dimensions of a housing to ensure a bearing fits properly, preventing assembly issues and ensuring the product functions as intended.

3. Best Practices for Using Measuring Tools

Calibration

Regular calibration is essential to maintain the accuracy of measuring tools. Over time, tools can become less accurate due to wear and tear. Calibration should be done using standard reference blocks or by a professional calibration service.

Proper Handling

Measuring tools are precision instruments and should be handled with care:

- Avoid dropping them, as this can damage the internal mechanisms.

- Keep them clean and free from debris, which can affect measurements.

- Store them in a protective case when not in use.

Training

Proper training is necessary to use measuring tools effectively. Understanding how to read a vernier scale or interpret the results from a dial indicator ensures accurate measurements. Many manufacturers provide training resources or tutorials for their tools.

4. Choosing the Right Measuring Tool

When selecting a measuring tool, consider the following factors:

- Accuracy Required: Determine the level of precision needed for your task. A digital caliper may be sufficient for general measurements, but a micrometer is necessary for high-precision work.

- Type of Measurement: Consider whether you need to measure internal, external, or depth dimensions, or if you need to check for deviations (using a dial indicator).

- Environment: In harsh environments (e.g., high humidity, dust), choose tools with appropriate protection (e.g., IP-rated digital calipers).

5. The Future of Measuring Tools

The field of measuring tools is constantly evolving, with advancements in digital technology and automation. Some trends include:

- Smart Measuring Tools: Tools with built-in sensors and wireless connectivity, allowing for real-time data collection and analysis.

- Automated Inspection Systems: Integrated systems that use multiple measuring tools to automate the inspection process, increasing efficiency and reducing human error.

In conclusion, measuring tools are indispensable in the hardware and metalworking industries. By understanding the different types of tools, their applications, and best practices for use, professionals can ensure precision and quality in their work. Whether you are a seasoned machinist or a DIY enthusiast, investing in quality measuring tools and learning how to use them effectively will elevate your projects to the next level.

By mastering these tools, you empower yourself to create with accuracy and confidence, ensuring that every project meets the highest standards of quality.