Mastering Milling Cutters: A Comprehensive Guide for Machining Success

The Basics of Milling Cutters

What Exactly is a Milling Cutter?

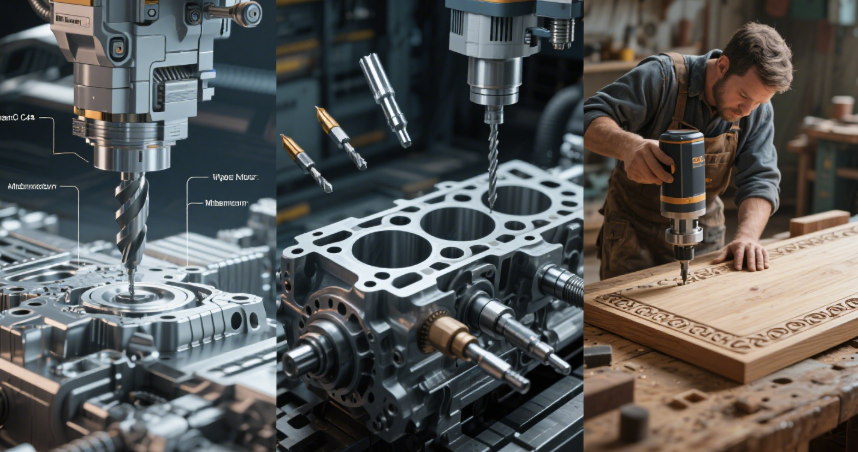

A milling cutter is a rotary cutting tool used in milling machines to remove material from a workpiece. Unlike a drill bit, which primarily makes holes, a milling cutter can perform a wide range of operations, including cutting slots, shaping contours, and creating flat surfaces. It consists of a shank that fits into the milling machine’s spindle and a cutting head with multiple teeth or flutes. These flutes play a crucial role in chip evacuation, ensuring a smooth cutting process.

Types of Milling Cutters

- End Mills

- Flat-End Mills: As the name implies, these have a flat tip and are ideal for tasks such as face milling, slotting, and side milling. For example, in a metalworking shop, a flat-end mill might be used to create a flat surface on a steel block. They typically come in 2, 3, or 4-flute configurations. A 2-flute flat-end mill is great for roughing operations, as it allows for faster chip evacuation. In contrast, a 4-flute one offers a smoother finish, making it suitable for finishing operations.

- Ball-Nose End Mills: With a rounded tip, these are designed for 3D contouring and machining curved surfaces. In the mold-making industry, ball-nose end mills are commonly used to create intricate shapes in molds. They often have 4 or more flutes to ensure a precise and smooth cut on curved surfaces.

- Corner-Radius End Mills: These combine the features of flat-end and ball-nose mills, with a flat tip and rounded corners. They are useful for applications where you need to prevent sharp edges and reduce wear, such as in the machining of parts that will be subject to stress.

- Face Mills

Face mills are used for machining flat surfaces, typically with a large diameter. They can be either solid or indexable. Indexable face mills have replaceable inserts, which makes them cost-effective as the inserts can be replaced when worn out. In a production line manufacturing large metal plates, face mills are used to quickly and efficiently create smooth, flat surfaces.

- Slot Drills

Slot drills are specialized milling cutters designed specifically for cutting slots. They have a straight or helical flute design and are available in various diameters. In the electronics industry, slot drills might be used to create slots in circuit boards for component installation.

Applications of Milling Cutters

Aerospace Industry

In the aerospace industry, precision is of utmost importance. Milling cutters are used to machine parts for aircraft engines, landing gear, and airframes. For instance, high-performance end mills are used to create complex shapes in titanium alloy components. Titanium is a difficult material to machine, but with the right milling cutter and cutting parameters, it’s possible to achieve the tight tolerances required in aerospace applications.

Automotive Industry

The automotive industry relies heavily on milling cutters for manufacturing engine blocks, transmission components, and brake parts. In the production of engine blocks, face mills are used to create flat mating surfaces, while end mills are used to machine intricate oil galleries and coolant passages. The high volume of production in the automotive industry requires milling cutters that are both durable and efficient.

Woodworking and DIY Projects

Milling cutters are not just for metalworking. In woodworking, they are used to shape and profile wooden components. For example, a router bit (a type of milling cutter) can be used to create decorative edges on wooden furniture. DIY enthusiasts might use a simple end mill to modify or create parts for their projects, such as milling a slot in a piece of aluminum for a custom electronics enclosure.

Choosing the Right Milling Cutter

Consider the Workpiece Material

The material of the workpiece is a crucial factor in choosing a milling cutter. For soft materials like aluminum, a high-speed steel (HSS) or carbide milling cutter with a large helix angle can be used. The large helix angle helps with chip evacuation, preventing the chips from clogging the flutes. On the other hand, for hard materials such as hardened steel or titanium, carbide or even diamond-coated milling cutters are more suitable. Carbide has excellent hardness and wear resistance, making it ideal for machining tough materials.

Determine the Machining Operation

The type of machining operation you need to perform will also guide your choice of milling cutter. If you’re doing face milling, a face mill is the obvious choice. For slotting, a slot drill or a flat-end mill with the appropriate diameter would be used. When contouring, a ball-nose or corner-radius end mill is required.

Evaluate the Cutting Parameters

Cutting parameters such as speed, feed, and depth of cut also influence the selection of a milling cutter. High-speed machining requires a milling cutter that can withstand the high rotational speeds and associated forces. In such cases, carbide cutters with advanced coatings are often used. The feed rate and depth of cut should be adjusted according to the material being machined and the type of milling cutter. For example, a high feed rate might be suitable for roughing operations but could cause the cutter to break if used in a finishing operation.

Maintaining Milling Cutters

Proper Storage

When not in use, milling cutters should be stored properly to prevent damage. They should be kept in a clean, dry place, preferably in a cutter holder or a storage case designed for milling cutters. This helps to protect the cutting edges from rust and physical damage. For example, carbide milling cutters are sensitive to moisture, so storing them in a humid environment can lead to corrosion and reduced performance.

Regular Cleaning

After each use, milling cutters should be cleaned to remove chips and debris. A brush can be used to clean the flutes and cutting edges. For stubborn chips, a mild solvent might be used. In a production environment, automated cleaning systems can be used to ensure that the cutters are thoroughly cleaned before the next use.

Sharpening and Reconditioning

As milling cutters wear out, they need to be sharpened or reconditioned. HSS cutters can be sharpened using a bench grinder, while carbide cutters often require specialized diamond grinding wheels. In some cases, if the cutter is too worn out, it might be more cost-effective to replace it rather than attempting to recondition it.

Conclusion

Milling cutters are essential tools in the machining world, enabling a wide range of operations on various materials. By understanding their types, applications, selection criteria, and maintenance requirements, you can make the most of these tools in your machining projects. Whether you’re a professional machinist or a hobbyist, choosing the right milling cutter and taking proper care of it will ensure that you achieve high-quality results and extend the lifespan of your tools. So, the next time you embark on a machining project, remember the insights shared in this blog to master the art of using milling cutters.