Drill Bits: Mastering Precision and Performance in Metalworking

In the realm of metalworking, drill bits are the unsung heroes, quietly shaping projects from delicate electronics to robust machinery. But not all drill bits are created equal—understanding their design, materials, and best practices can transform your work. Let’s dive into the world of drill bits, from choosing the right type to extending their life, with data – backed insights and practical tips.

1. Anatomy of a Drill Bit: Beyond the Point

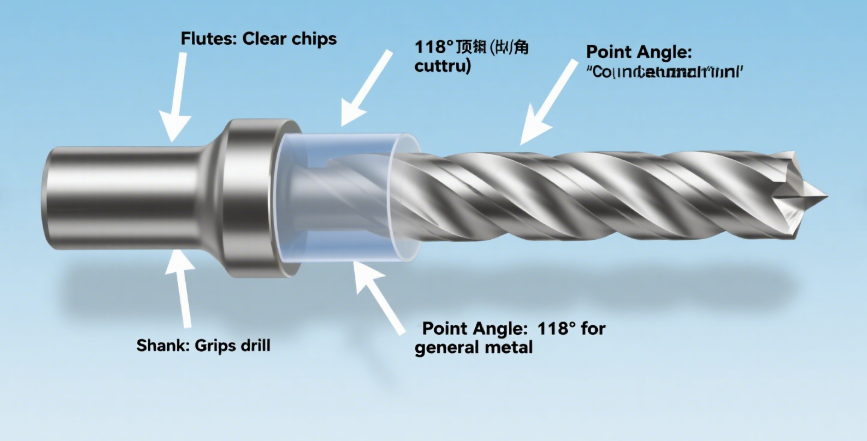

A drill bit might look simple, but its design is a masterclass in engineering. Here’s a breakdown:

- Flutes: These spiral grooves aren’t just for looks—they channel chips away, preventing jams and overheating. Twist drills (the most common type) typically have 2 flutes, but some specialty bits (like those for stainless steel) use 3 or 4 for better chip control.

- Point Angle: Standard bits have a 118° angle, ideal for general – purpose metal drilling. For harder materials like alloy steel, a steeper 135° angle reduces friction and prevents “walking” (skipping across the surface).

- Shank: The part that fits into the drill—round shanks work with most chucks, while hex shanks lock into impact drivers for heavy – duty jobs.

2. Material Matters: Choosing the Right Bit for the Job

Drill bit materials dictate performance—here’s how to pick:

- High – Speed Steel (HSS): Affordable and versatile, HSS bits handle mild steel, aluminum, and wood. They work best at lower speeds (around 300–500 RPM for metal) and can be sharpened repeatedly.

- Cobalt (HSS – Co): With 5–8% cobalt, these bits tackle stainless steel, cast iron, and other tough metals. Their heat resistance lets you drill at higher speeds (up to 800 RPM) without dulling.

- Carbide: The hardest option, carbide bits drill through hardened steel, titanium, and composites. They’re brittle but last 10–20x longer than HSS—worth the investment for high – volume jobs.

Data Tip: In tests, a cobalt bit drilled 30+ holes in 316 stainless steel before needing sharpening, while an HSS bit dulled after 5–7 holes.

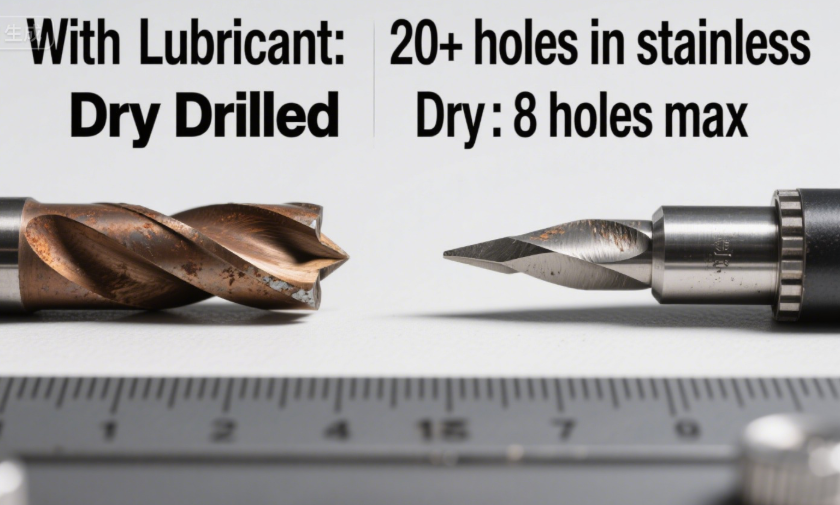

3. Coolant and Lubrication: Extend Bit Life by 50%

Heat is the enemy of drill bits—coolant (or lubricant) reduces friction, lowers temperatures, and extends life. Here’s how:

- Flood Cooling: For industrial drilling, a steady stream of coolant (like water – based emulsions) keeps bits below 200°C, preventing edge wear.

- Paste Lubricants: For hand – held jobs, a dab of cutting oil or wax on the drill point reduces heat. In tests, using lubricant doubled the number of holes a cobalt bit could drill in brass.

- Dry Drilling: Only for soft materials (like aluminum) or small – diameter bits—hard metals will quickly overheat bits without cooling.

Pro Tip: For stainless steel, use a sulfur – based lubricant to break down tough chips.

4. Sharpening: Bring Dull Bits Back to Life

A dull drill bit doesn’t just work slower—it produces rough holes and risks breaking. Sharpening saves money:

- Bench Grinder: Use a 60 – grit wheel to re – shape the point angle. For HSS bits, keep the wheel cool (dip bits in water) to avoid overheating.

- Sharpening Jigs: These guide bits at the correct angle (118° or 135°) for consistent results, even for beginners.

- When to Retire a Bit: If the cutting edges are chipped or the flute is clogged beyond cleaning, it’s time to replace—dull bits cause 30% more drilling time and 2x more scrap.

Data Insight: A sharpened HSS bit performs almost as well as a new one—saving 80% of the cost of replacement.

5. Troubleshooting Common Drill Bit Issues

Even pros face problems—here’s how to fix them:

- Bit Walking: Use a center punch to start a dimple, or reduce speed and apply steady pressure. A 135° point angle also helps.

- Broken Bits: Soak the workpiece in penetrating oil, then use a small extractor or reverse – twist a drill to remove the shard.

- Rough Holes: Check for dull edges, adjust speed (slower for hard metals), or use coolant. For stainless steel, a slow speed (200–300 RPM) with lubricant yields smooth holes.

Final Thoughts: Treat Bits Right, Reap Results

Drill bits are an investment—choosing the right type, using coolant, and sharpening wisely boosts efficiency and quality. Whether you’re drilling aluminum for a hobby project or tackling hardened steel in a factory, these tips ensure your bits work harder, longer, and more precisely.

By mastering drill bit basics, you’ll cut costs, reduce scrap, and turn metalworking challenges into smooth, precise holes—every time. Stay sharp!