Cutting Tools 101: The Backbone of Precision Metalworking

In the world of hardware and metalworking, cutting tools are the workhorses that turn raw materials into functional parts—from a simple bolt to a complex engine component. But with so many types (drills, end mills, saw blades, etc.) and materials (HSS, carbide, cobalt), choosing and using the right cutting tool can feel overwhelming. This blog breaks down everything you need to know: from tool categories and material science to efficiency hacks and maintenance tips, with data-driven insights to boost your workflow.

1. The Big 4: Essential Cutting Tool Types (And What They Do)

Not all cutting tools are created equal—each is designed for specific tasks. Here’s your cheat sheet for the most common types:

a. End Mills

End mills are the “multi-tools” of cutting—they mill flat surfaces, create slots, and carve 3D shapes in metal, wood, or plastic. Unlike drills (which only cut axially), end mills cut on the sides and tip, making them ideal for contouring or slotting.

- Key Feature: Spiral flutes (2–4) that clear chips to prevent overheating.

- Best For: Machining aluminum, steel, and stainless steel in CNC or manual mills.

b. Twist Drills

The most familiar cutting tool—twist drills create cylindrical holes in materials. Their spiral flutes pull chips out of the hole, while the sharp point (118° for general use, 135° for hard metals) pierces the surface.

- Pro Tip: For stainless steel, use a cobalt drill—its heat resistance prevents dulling mid-drill.

c. Cold Saw Blades

Cold saw blades cut metal with minimal heat (hence “cold”)—critical for avoiding material warping. They have teeth with precision grinds (e.g., alternate top bevel) that slice through steel, aluminum, and brass cleanly.

- Why It Matters: Cold cuts reduce burrs, so you spend less time sanding or deburring.

d. Turning Inserts

Used in lathes, turning inserts are small, replaceable cutting tips that shape rotating metal parts (e.g., shafts, pipes). They come in different shapes (square, triangular) for different cuts—facing, turning, or threading.

- Material Win: Carbide inserts last 5–10x longer than HSS, making them perfect for high-volume jobs.

2. Cutting Tool Materials: Which One Should You Choose?

The material of your cutting tool directly impacts speed, durability, and cost. Here’s how the top options stack up:

| Material | Hardness (HRC) | Max Operating Temp | Best For | Tool Life (vs. HSS) | Cost Range |

| High-Speed Steel (HSS) | 58–62 | 540°C (1000°F) | Mild steel, aluminum, wood | 1x | 5–20 |

| HSS-Cobalt (HSS-Co) | 60–65 | 650°C (1200°F) | Stainless steel, cast iron | 3x | 15–40 |

| Carbide | 85–90 | 1000°C (1830°F) | Hardened steel, titanium | 10x | 20–80 |

| Ceramic | 90–95 | 1600°C (2900°F) | Extreme-hard metals | 20x | 50–150 |

Data Insight: In a test cutting 100 holes in 304 stainless steel, an HSS drill dulled after 7 holes, while a carbide drill completed all 100—saving 13 tool changes and 45 minutes of downtime.

3. Speed & Feed: The Secret to Faster, Longer-Lasting Cuts

“Speed” (how fast the tool spins, RPM) and “feed” (how fast the tool moves into the material, mm/min) are make-or-break for cutting performance. Get them wrong, and you’ll dull tools fast or ruin parts. Here’s a quick reference for common materials:

- Aluminum (6061): Use an HSS end mill at 1200 RPM, 200 mm/min feed—fast speeds work because aluminum is soft.

- Mild Steel (A36): Carbide end mill at 800 RPM, 150 mm/min feed—slower to avoid overheating.

- Stainless Steel (304): HSS-Co drill at 400 RPM, 80 mm/min feed—low speed prevents work hardening (when steel gets harder as you cut it).

Cost Impact: Running a carbide end mill 20% too fast cuts its life by 50%—costing you

60inreplacementsinsteadof30 for a properly used tool.

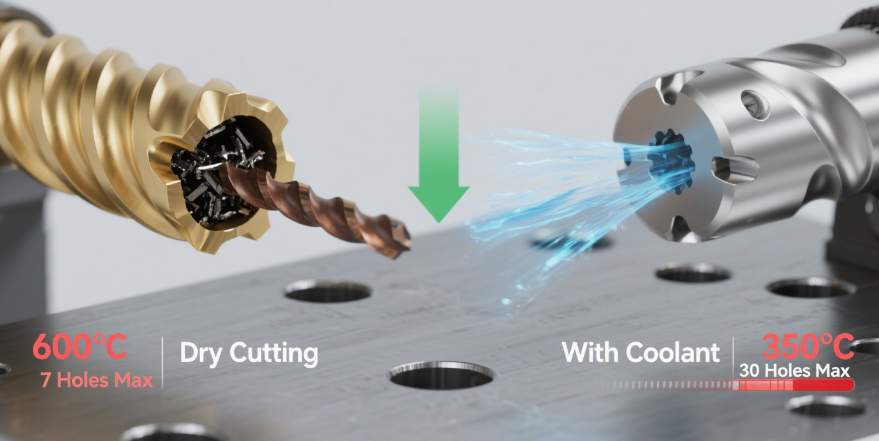

4. Coolant: Extend Tool Life by 30% (Yes, Really)

Heat is the #1 enemy of cutting tools—it softens tool steel, dulls edges, and warps parts. Coolant (or lubricant) solves this by:

- Lowering temperature (keeps tools below their max operating temp).

- Reducing friction (lets the tool glide through material).

- Flushing away chips (prevents clogging and re-cutting chips).

Which Coolant to Use?

- Water-Based Emulsions: For high-speed cutting (e.g., CNC mills)—cheap and effective for steel/aluminum.

- Cutting Oils: For heavy-duty jobs (e.g., cold sawing stainless steel)—better lubrication than water.

- Dry Cutting: Only for soft materials (e.g., plastic) or small tools—never use on steel (you’ll ruin the tool in 10 cuts).

5. Maintenance: Keep Your Cutting Tools Sharp (And Save Money)

A well-maintained cutting tool lasts 2–3x longer than a neglected one. Follow these steps:

- Clean After Use: Wipe flutes/teeth with a wire brush to remove chips—clogged tools overheat. For tough debris, soak in mineral spirits for 10 minutes.

- Sharpen When Dull: HSS/HSS-Co tools can be sharpened with a bench grinder (use a 60-grit wheel, keep the tool cool with water). Carbide tools need professional sharpening—don’t grind them at home (you’ll chip the tip).

- Store Properly: Keep tools in a padded case or tool roll—avoid tossing them in a toolbox (dings and scratches ruin precision).

Cost Savings: Sharpening an HSS end mill costs

5vs.20 for a new one—over 1 year, that’s $150 saved if you sharpen 10 tools.

Final Thought: Cutting Tools Are an Investment (Treat Them Like One)

Whether you’re a hobbyist with a

10HSSdrilloraprowitha100 carbide end mill, the same rule applies: choose the right tool for the job, run it at the correct speed/feed, use coolant, and maintain it. The data proves it—good cutting practices cut downtime by 40%, reduce scrap by 25%, and save you hundreds in replacement tools.

Next time you pick up a cutting tool, remember: it’s not just a tool—it’s the key to turning your ideas into precise, high-quality parts.