Cold Saw Blades: Unleashing Precision in Metal Cutting

In the world of metalworking, precision and efficiency are non – negotiable. Cold saw blades have emerged as a game – changer, enabling clean, accurate cuts with minimal heat generation. This blog dives deep into the realm of cold saw blades, exploring their technology, applications, and how to choose the right one for your metal – cutting needs.

How Cold Saw Blades Work: The Science Behind the Cool Cut

Cold sawing is a process where the heat generated during cutting is effectively transferred to the chips, keeping the workpiece and the saw blade cool. This is in contrast to traditional hot sawing methods, which can cause material distortion and reduce the quality of the cut.

Cold saw blades typically operate at lower speeds compared to other saw blades, but they compensate with higher torque. The teeth of the cold saw blade are designed to shear the material rather than melt or burn it, resulting in a cleaner cut surface. For example, when cutting a solid steel bar, a cold saw blade will remove material in small, controlled chips, leaving a smooth finish that often requires little to no secondary processing.

Types of Cold Saw Blades: High – Speed Steel (HSS) vs. Tungsten Carbide – Tipped (TCT)

High – Speed Steel (HSS) Cold Saw Blades

- Material Composition: HSS cold saw blades are commonly made from M2 or M35 steel. M2 is a standard high – speed steel, while M35 contains around 5% cobalt, which enhances its performance when cutting hard materials like stainless steel.

- Performance Characteristics: These blades can achieve cutting speeds in the range of 10 – 150 meters per second, depending on the material and size of the workpiece. Coated HSS blades can reach speeds of up to 250 meters per minute. They have a hardness of around HRC 65, which allows them to maintain their cutting edge for a reasonable number of cuts.

- Sharpening and Longevity: HSS blades are often re – sharpenable. Depending on the workpiece, they can be sharpened 15 – 20 times. Their sawing life is typically measured in terms of the area of the workpiece’s cross – section, usually ranging from 0.3 – 1 square meter. Larger HSS blades (over 2000 mm) may use a design where the teeth are made of high – speed steel and the blade’s body is made of vanadium or manganese steel.

Tungsten Carbide – Tipped (TCT) Cold Saw Blades

- Material Composition: TCT blades have a steel body with tungsten carbide inserts brazed onto the tips. Tungsten carbide is an extremely hard and wear – resistant material, making it ideal for cutting tough metals.

- Performance Characteristics: TCT cold saw blades can operate at higher speeds, typically between 60 – 380 meters per second. The tooth feed rate for tungsten carbide blades is usually in the range of 0.04 – 0.08. They are more suitable for high – production cutting environments due to their ability to maintain a sharp edge for longer periods.

- Advantages over HSS: Tungsten carbide is more heat – resistant than HSS, allowing TCT blades to run at higher speeds without losing their cutting edge. Additionally, the wear – resistance of tungsten carbide means that TCT blades generally have a longer service life compared to HSS blades.

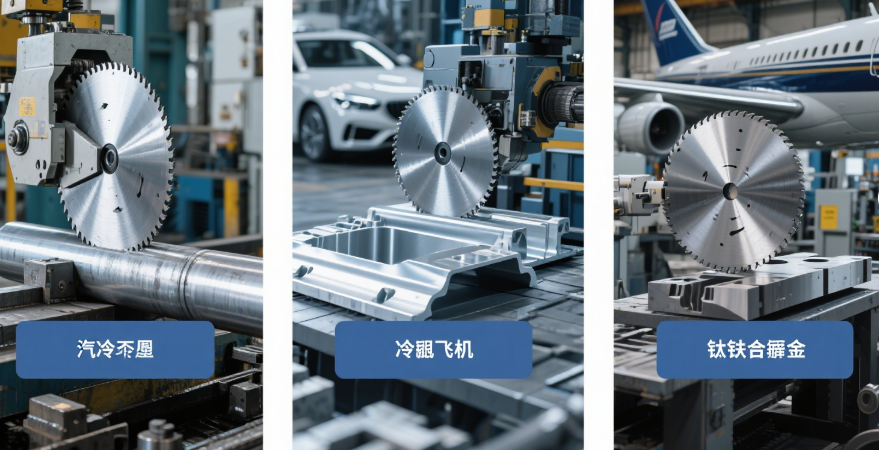

Applications of Cold Saw Blades: Where Precision Matters

Cold saw blades are incredibly versatile and find applications in a wide range of industries.

Metal Fabrication

- In metal fabrication shops, cold saw blades are used to cut various metal shapes, including solid bars, tubes, pipes, angle iron, and structural shapes. The ability to make precise cuts without distorting the material is crucial for ensuring that the fabricated parts fit together perfectly. For example, when creating a metal frame for a piece of machinery, cold saw blades can cut the metal bars to the exact length and angle required, reducing the need for additional finishing work.

Automotive Industry

- In the automotive industry, cold saw blades are used to cut components made from different metals, such as steel, aluminum, and alloy steels. Whether it’s cutting engine parts, suspension components, or body panels, the precision and clean cuts provided by cold saw blades are essential for maintaining the quality and performance of the vehicles.

Aerospace Industry

- The aerospace industry demands the highest level of precision in metal cutting. Cold saw blades are used to cut aircraft components made from special alloys, where even the slightest deviation in the cut can compromise the safety and performance of the aircraft. The ability of cold saw blades to cut with minimal heat generation is particularly important when working with heat – sensitive aerospace materials.

Choosing the Right Cold Saw Blade: Factors to Consider

Material of the Workpiece

- Different materials require different types of cold saw blades. For example, HSS blades are suitable for cutting softer metals like mild steel, while TCT blades are better for harder materials such as stainless steel, alloy steels, and non – ferrous metals like aluminum, brass, and copper. When cutting materials with high tensile strength, blades with cobalt – enhanced HSS or TCT blades are often the best choice.

Cutting Speed and Feed Rate

- The cutting speed and feed rate of the cold saw machine should be matched with the capabilities of the saw blade. HSS blades generally operate at lower speeds compared to TCT blades. If the cutting speed is too high for the blade, it can cause premature wear and damage to the blade. Similarly, the feed rate, which is the rate at which the workpiece is fed into the blade, should be adjusted according to the material and the type of blade being used.

Blade Size and Tooth Configuration

- The size of the cold saw blade should be appropriate for the size of the workpiece and the saw machine. Larger workpieces may require larger blades, while smaller, more intricate cuts may be better suited for smaller blades. The tooth configuration of the blade also plays a crucial role. For example, a triple – chip tooth form is commonly used for cutting carbon steel, alloy steels, and stainless steel, as it helps to reduce the cutting forces and improve the quality of the cut.

Maintenance and Care of Cold Saw Blades: Prolonging Their Lifespan

Regular Cleaning

- After each use, cold saw blades should be cleaned to remove any chips, debris, or coolant residue. This can be done using a soft brush or a compressed air gun. Cleaning the blade not only helps to maintain its cutting performance but also prevents the build – up of contaminants that could cause corrosion or damage to the blade.

Sharpening

- As mentioned earlier, many cold saw blades, especially HSS blades, are re – sharpenable. Regular sharpening can extend the lifespan of the blade significantly. However, it’s important to use the correct sharpening equipment and techniques to ensure that the blade’s cutting edge is maintained properly. For TCT blades, the tungsten carbide tips may require professional sharpening services to ensure that the brazed joints are not damaged.

Storage

- When not in use, cold saw blades should be stored in a clean, dry place. They should be hung or placed in a protective case to prevent them from getting scratched or damaged. Blades made from materials that are prone to rust, such as some types of HSS blades, may benefit from being coated with a light layer of oil to prevent corrosion during storage.

Cold saw blades are an essential tool for anyone involved in metal cutting. By understanding their working principles, types, applications, and how to maintain them, you can make the most of these precision – cutting tools and achieve outstanding results in your metalworking projects.