Circular Cold Saw Blades: The Ultimate Guide to Clean, Cool Metal Cutting

In metal fabrication—whether you’re cutting rebar for construction, stainless steel tubes for plumbing, or aluminum extrusions for automotive parts—circular cold saw blades stand out as the gold standard for precision and efficiency. Unlike abrasive saws (which generate extreme heat and rough edges) or band saws (which are slow for high-volume jobs), cold saw blades cut through metal at low temperatures, leaving smooth, burr-free finishes and minimizing material waste.

This guide dives into everything you need to master circular cold saw blades: from understanding how they work (and why they’re better than other tools) to choosing the right blade for your material (steel, aluminum, copper) and maintaining it for thousands of cuts. We’ll also debunk common myths (e.g., “cold saws only work for thick metal”) and share pro tips for avoiding blade damage. By the end, you’ll know exactly how to get the most out of this essential metalworking tool.

What Are Circular Cold Saw Blades, and How Do They Work?

A circular cold saw blade is a specialized cutting tool designed for low-heat, high-precision metal cutting. Unlike abrasive blades (which grind away material) or hot saws (which rely on friction to melt through metal), cold saw blades use:

- Sharp, hardened teeth (often made of carbide or high-speed steel) to shear through metal (like a pair of scissors cutting paper).

- Slow rotational speeds (50–500 RPM, vs. 3,000+ RPM for abrasive saws) to minimize friction and heat.

- Coolant systems (flood or mist) to further reduce temperature and protect both the blade and workpiece.

Key Benefits of Cold Saw Blades (vs. Other Cutting Tools)

| Feature | Circular Cold Saw Blades | Abrasive Saws | Band Saws |

| Cutting Temperature | Low (<150°C) – no material warping | High (>500°C) – causes warping/discoloration | Medium (200–300°C) – minor warping |

| Surface Finish | Smooth, burr-free – no post-processing | Rough, jagged – needs deburring | Smooth but slow – better for thin metal |

| Cutting Speed (Thick Steel) | Fast (1–2 minutes per 50mm bar) | Slow (3–5 minutes per 50mm bar) | Very slow (5–10 minutes per 50mm bar) |

| Blade Life | Long (10,000+ cuts for carbide) | Short (500–1,000 cuts) | Medium (2,000–5,000 cuts) |

| Material Waste | Minimal (thin kerf – 1–2mm) | High (thick kerf – 3–5mm) | Low (thin kerf) but slow |

How Cold Saws Avoid Heat Damage

The “cold” in cold saw blades isn’t just a marketing term—it’s a result of two design choices:

- Shear Cutting: Teeth slice through metal instead of grinding it, which generates 70% less heat than abrasive cutting.

- Slow Speed: Lower RPM means less friction between the blade and workpiece. For example, cutting a 20mm stainless steel bar with a cold saw at 150 RPM produces barely enough heat to warm the metal (you can touch it immediately after cutting).

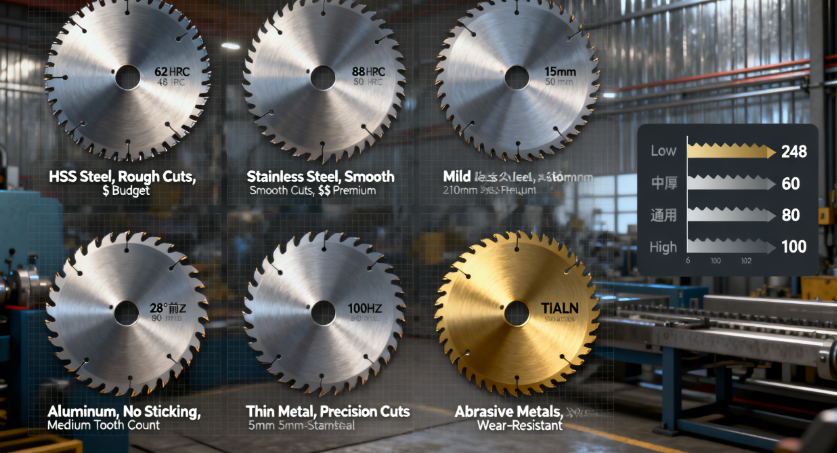

Types of Circular Cold Saw Blades (Choose by Material & Application)

Not all cold saw blades work for every metal—blade design (tooth count, material, coating) is tailored to specific workpiece materials. Here’s how to pick the right one:

1. By Blade Material: HSS vs. Carbide

The two most common cold saw blade materials are High-Speed Steel (HSS) and Carbide-Tipped—each with distinct strengths:

| Blade Material | Hardness (HRC) | Best For Materials | Blade Life | Cost (Relative) |

| HSS (M2/M42) | 62–65 | Mild steel, aluminum, copper (soft metals) | 1,000–3,000 cuts | $ (Budget) |

| Carbide-Tipped (WC-Co) | 85–90 | Stainless steel, alloy steel, tool steel (hard metals) | 10,000–20,000 cuts | $$–$$$ (Premium) |

Pro Tip: For high-volume jobs (e.g., cutting 100+ steel bars daily), carbide-tipped blades are worth the investment—they last 5–10x longer than HSS and reduce downtime from blade changes.

2. By Tooth Count: More Teeth = Smoother Cuts

Tooth count determines surface finish and cutting speed—more teeth mean smoother cuts, but slower feed rates:

- Low Tooth Count (24–48 Teeth): Best for thick metal (20mm+) or rough cuts. For example, a 36-tooth carbide blade cuts 50mm mild steel bars quickly, with a slightly rough edge (easy to deburr).

- Medium Tooth Count (60–80 Teeth): Ideal for medium-thickness metal (10–20mm) and general use. A 60-tooth HSS blade cuts 15mm aluminum extrusions with a smooth finish—no post-processing needed.

- High Tooth Count (100–120 Teeth): For thin metal (≤10mm) or precision cuts. A 100-tooth carbide blade cuts 5mm stainless steel sheets with a mirror-like edge—perfect for decorative or structural parts.

3. Specialized Cold Saw Blades

- Aluminum-Specific Blades: Have a “high rake angle” (25–30°) to prevent aluminum from sticking to teeth (aluminum is soft and can clog blades).

- Stainless Steel Blades: Coated with TiAlN (Titanium Aluminum Nitride) to resist wear—stainless steel is abrasive and dulls uncoated blades quickly.

- Bi-Metal Blades: Combine HSS bodies with carbide tips—balances durability and cost for occasional hard metal cutting.

How to Use Circular Cold Saw Blades Correctly (Avoid Common Mistakes)

Even the best cold saw blade will fail with poor technique. Follow these steps for clean, efficient cuts—and to extend blade life:

1. Match Blade to Material (Critical!)

Using the wrong blade for your material is the #1 cause of premature wear. For example:

- Don’t use an HSS blade for stainless steel—it will dull after 10–20 cuts.

- Don’t use a low-tooth-count blade for thin aluminum—it will tear the metal instead of cutting it.

2. Set the Right Speed & Feed Rate

Speed (RPM) and feed rate (how fast the blade moves into the material) depend on blade type and material thickness. Use this cheat sheet:

| Material | Blade Type | Thickness | Speed (RPM) | Feed Rate (mm/min) |

| Mild Steel (1018) | HSS (48 teeth) | 20mm | 250 | 50–75 |

| Stainless Steel (304) | Carbide (60 teeth) | 15mm | 150 | 30–50 |

| Aluminum (6061) | Aluminum-Specific (80 teeth) | 10mm | 400 | 80–100 |

| Copper | HSS (60 teeth) | 12mm | 300 | 60–80 |

3. Use Coolant (Don’t Skip It!)

Coolant serves three key purposes:

- Reduces heat (prevents material warping and blade softening).

- Lubricates teeth (reduces friction and wear).

- Flushes away chips (prevents clogging).

For most metals: Use water-soluble coolant (mix 10–15% coolant with water). For aluminum: Use neat oil coolant (100% oil) to prevent aluminum from oxidizing.

4. Secure the Workpiece

Always clamp the metal to a stable workbench or cold saw table—unsecured material can “kick back” (jump toward the blade) or shift during cutting, causing uneven edges or blade damage. For long bars: Use a support roller to prevent sagging.

5. Inspect Blades Before Use

Check for these red flags before cutting:

- Dull Teeth: Look for rounded edges or metal buildup on teeth (use a magnifying glass for small teeth).

- Cracks: Inspect the blade body for tiny cracks—even a small crack can cause the blade to shatter at high speed.

- Warping: Place the blade on a flat surface—if it rocks, it’s warped and needs replacement.

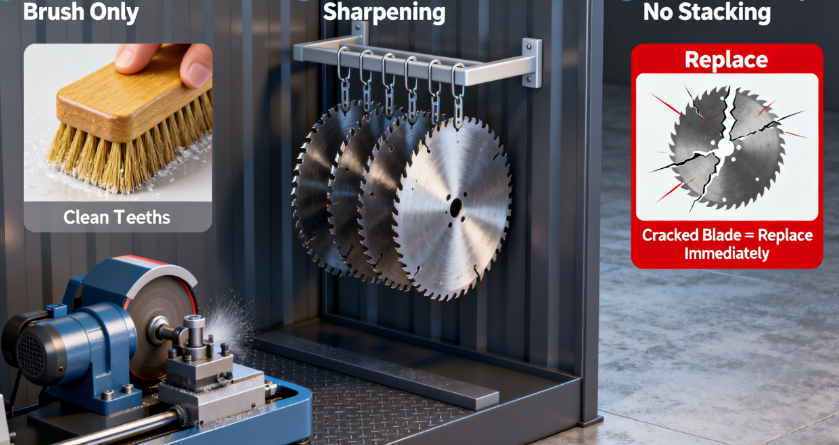

Maintenance: Extend Your Cold Saw Blade’s Life (Save Money!)

A quality carbide cold saw blade can cost

100–500—with proper care, it will last for years. Follow these maintenance tips:

1. Clean Blades After Every Use

- Remove Chips: Use a brass brush to scrub teeth (steel brushes scratch carbide). For aluminum buildup: Soak the blade in a degreaser (like mineral spirits) for 10 minutes, then brush gently.

- Dry Thoroughly: Wipe the blade with a lint-free cloth to prevent rust (especially for HSS blades).

2. Store Blades Properly

- Use a Blade Rack: Hang blades vertically on a dedicated rack—never stack them (teeth can chip).

- Avoid Moisture: Store blades in a dry, temperature-stable area (humidity causes rust on HSS blades).

- Protect Teeth: For unused blades, keep them in their original cardboard or plastic sleeve.

3. Sharpen Blades When Dull

- HSS Blades: Sharpen with a bench grinder (use a 60-grit aluminum oxide wheel). Follow the original tooth angle (usually 15–20°) to preserve cutting performance.

- Carbide-Tipped Blades: Don’t sharpen at home—carbide is too hard for standard grinders. Send them to a professional sharpening service (costs 20–50 per blade, vs. $100+ for a new one).

4. Replace Blades When Necessary

Replace your cold saw blade if:

- Sharpening no longer restores cutting speed (teeth are worn down to the base).

- The blade has cracks (even small ones—safety first!).

- The kerf (cut width) becomes wider than normal (sign of a warped or damaged blade).

Final Thoughts: Are Circular Cold Saw Blades Worth the Investment?

If you cut metal regularly—whether for a small shop or a large fabrication facility—cold saw blades are a no-brainer investment. They save time (faster cuts than band saws), reduce waste (thin kerf), and eliminate post-processing (no deburring needed). For example:

- A small plumbing company cutting 50 stainless steel tubes daily can save 2–3 hours per day with a cold saw (vs. an abrasive saw).

- A DIY metalworker can achieve professional-quality cuts with a budget HSS cold saw blade (no more jagged edges on custom projects).

Remember: The key to success with cold saw blades is matching the blade to your material, using coolant, and maintaining the blade properly. With these steps, your cold saw blade will deliver thousands of clean, cool cuts—making it one of the most valuable tools in your workshop.

Now, grab the right blade, clamp your material, and start cutting—your next perfect metal part is just a saw spin away!