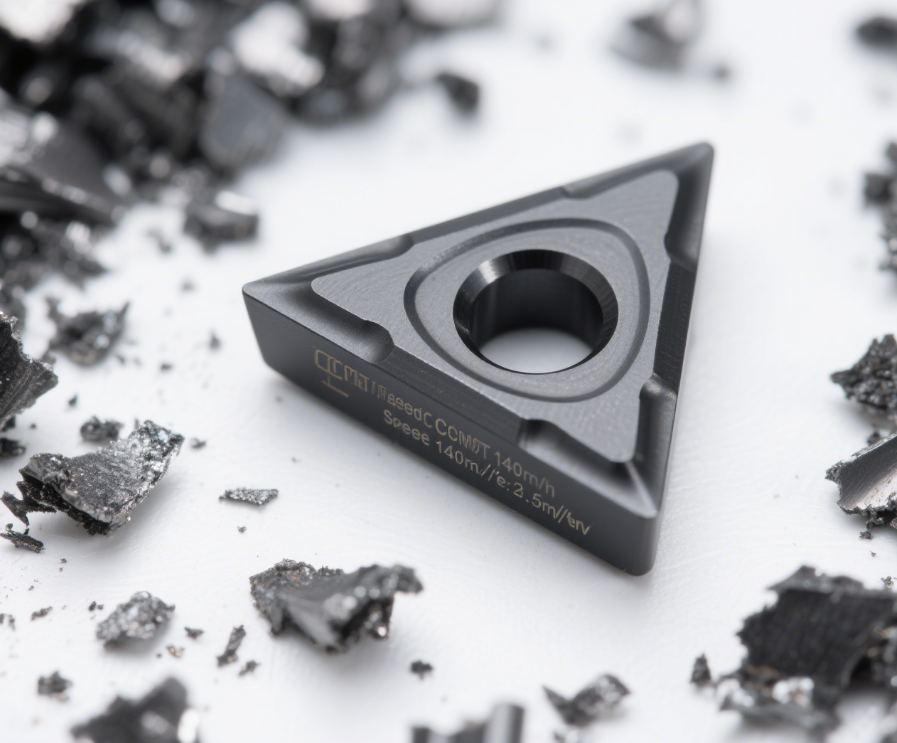

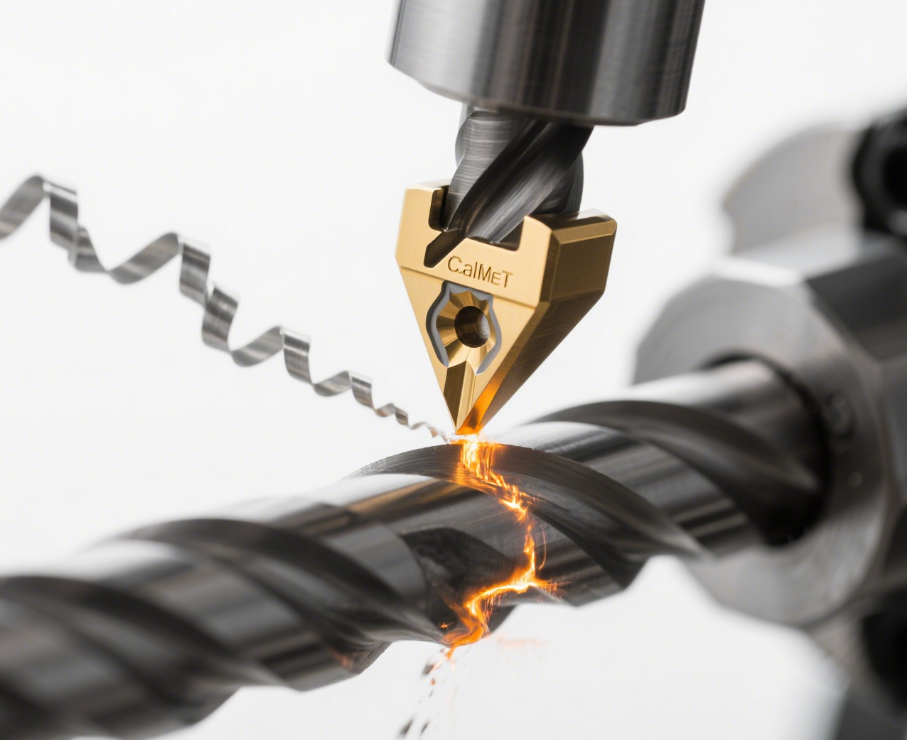

CCMT Turning Inserts: Groove Styles, Material Machinability, and Cutting Efficiency

In the realm of precision turning, CCMT (Corner Radius, Chamfer, Multi – layer coating, Tungsten carbide base) inserts stand out as versatile workhorses. Their performance hinges on three key aspects: groove styles, the materials they can machine, and the cutting speeds and efficiency they deliver. Let’s delve into these crucial elements.

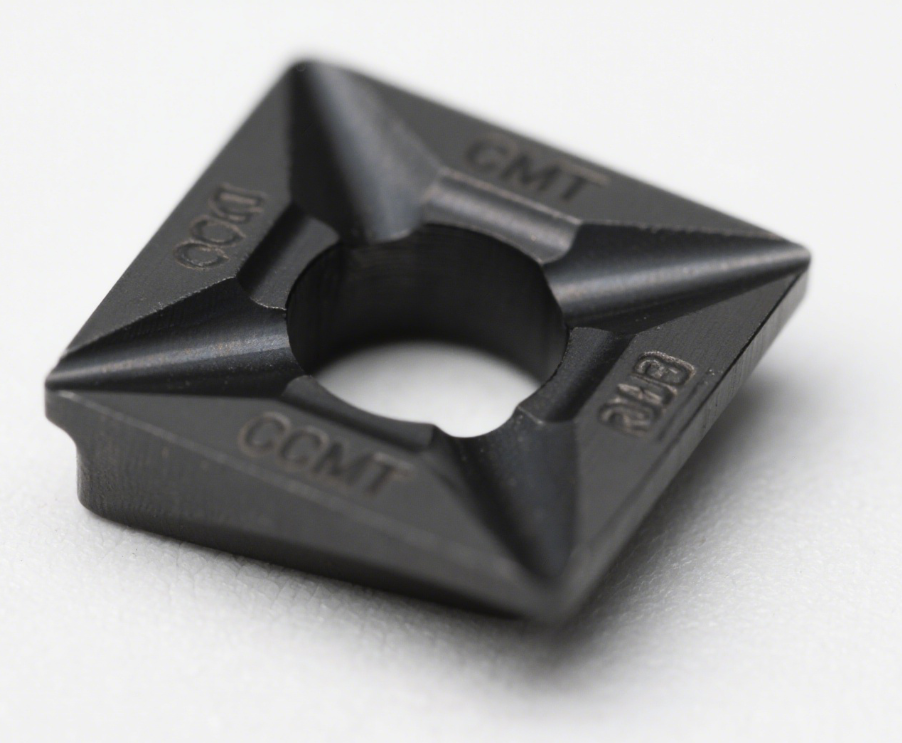

Groove Styles of CCMT Inserts

Neutral Groove

The neutral groove design on CCMT inserts offers a balanced approach. It provides moderate chip control and cutting forces, making it suitable for a wide range of general – purpose turning operations. This groove style is ideal when you need a reliable insert that can handle various materials without extreme demands on chip evacuation or cutting force reduction.

Positive Groove

CCMT inserts with positive grooves are engineered for reduced cutting forces. The sharp cutting edge and optimized groove angle allow for easier penetration into the workpiece, making them excellent for machining materials that are prone to work – hardening, such as stainless steel. The positive groove also promotes efficient chip flow, minimizing the risk of chip jamming.

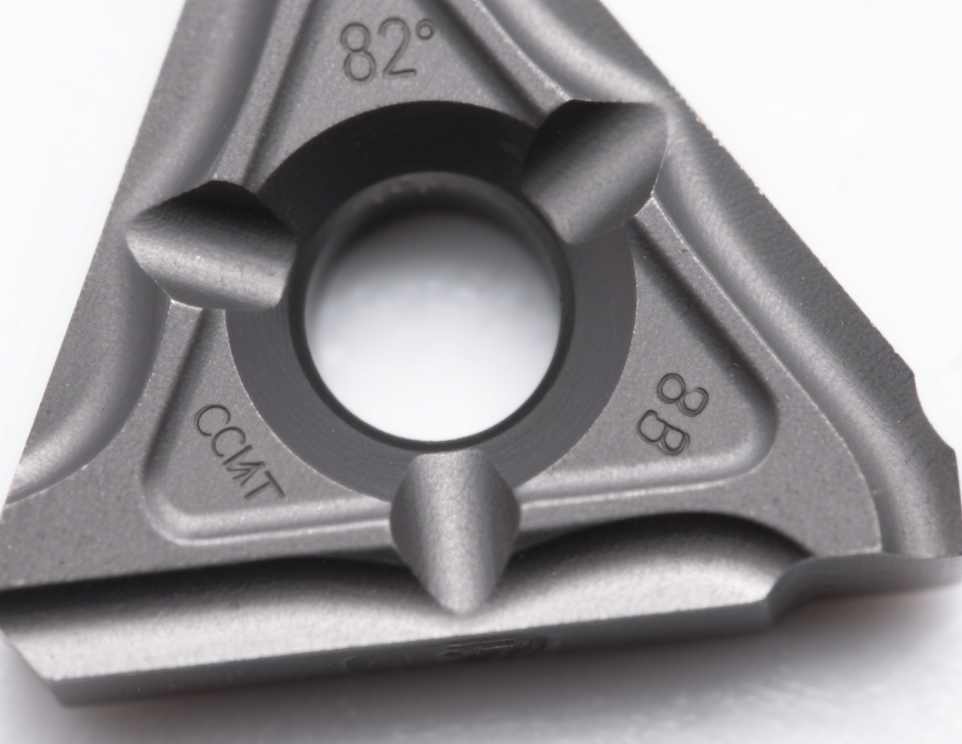

Negative Groove

Negative groove CCMT inserts boast high strength at the cutting edge. This makes them well – suited for heavy – duty turning operations, where high cutting forces and interrupted cuts are common. The robust groove design helps to resist edge chipping and extends tool life in demanding applications like rough turning of cast iron.

Machining Materials with CCMT Inserts

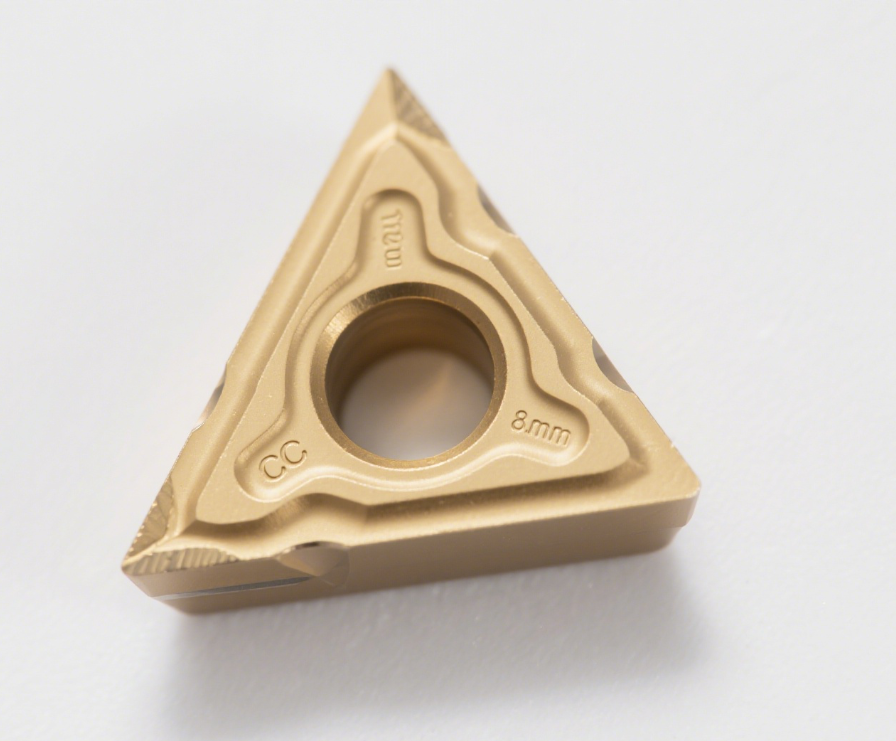

Steel

CCMT inserts excel in turning steel, whether it’s carbon steel, alloy steel, or tool steel. The right combination of groove style and coating (such as TiAlN or TiCN) ensures good wear resistance and thermal stability. For example, when turning medium – carbon steel for automotive components, a CCMT insert with a neutral groove and TiAlN coating can provide a good balance of tool life and surface finish.

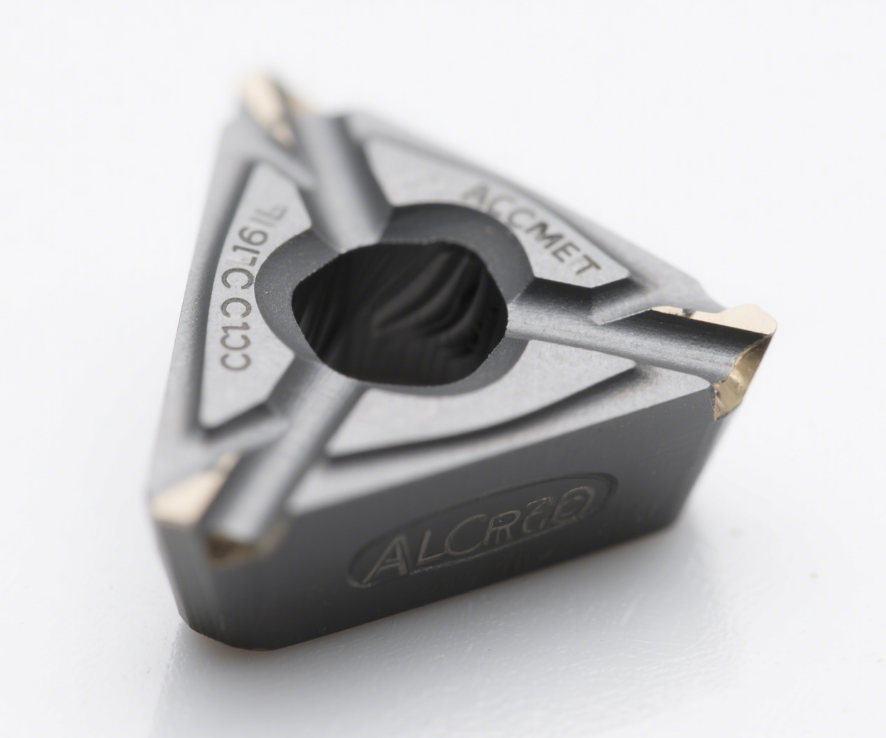

Stainless Steel

Machining stainless steel poses challenges due to its work – hardening nature and poor thermal conductivity. CCMT inserts with positive grooves and specialized coatings are designed to tackle these issues. The positive groove reduces cutting forces, while coatings like AlCrN enhance heat resistance, allowing for more efficient turning of stainless steel parts used in the aerospace industry.

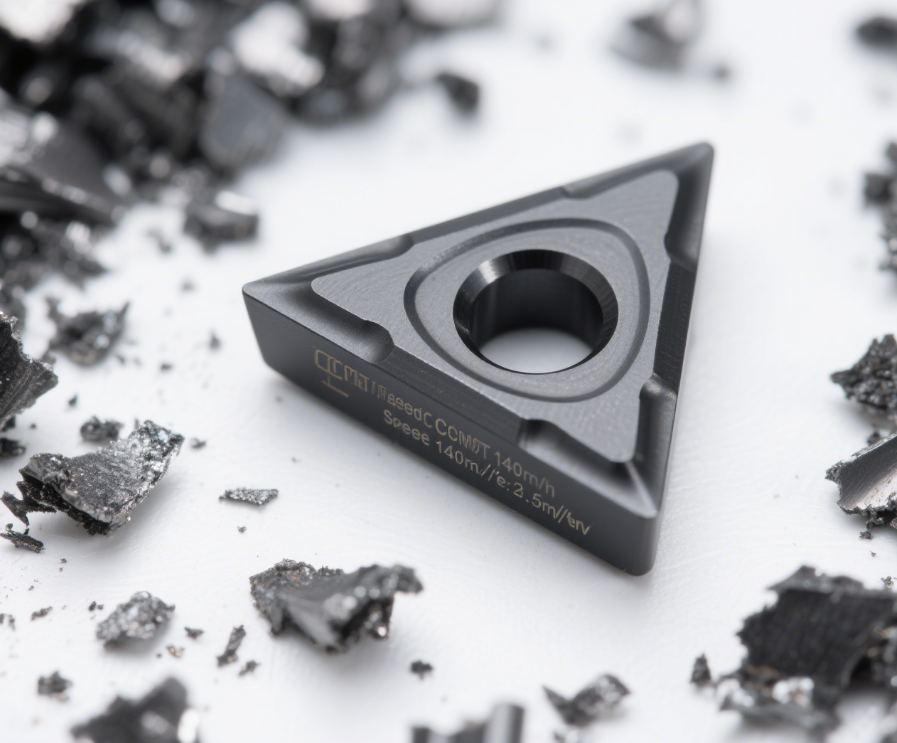

Cast Iron

For cast iron, which is often abrasive and can cause rapid tool wear, CCMT inserts with negative grooves and wear – resistant coatings are the go – to choice. The strong cutting edge of the negative groove withstands the abrasive nature of cast iron, and coatings like diamond – like carbon (DLC) provide extra protection, ensuring longer tool life when turning cast iron engine blocks.

Cutting Speed and Efficiency

Optimal Cutting Speeds

The optimal cutting speed for CCMT inserts varies depending on the material being machined and the insert’s groove style. For steel, speeds typically range from 100 – 250 m/min. When machining stainless steel, speeds are lower, around 50 – 150 m/min, to control heat generation. For cast iron, speeds can be in the range of 80 – 200 m/min, depending on the insert’s durability.

Efficiency Enhancements

To maximize efficiency with CCMT inserts, several strategies can be employed. Using the correct groove style for the material reduces cutting forces and tool wear, allowing for higher feed rates. Additionally, modern coatings and advanced carbide substrates enable faster cutting speeds without sacrificing tool life. Proper tool geometry, including the insert’s corner radius, also plays a role in chip control and surface finish, further enhancing overall turning efficiency.

CCMT turning inserts, with their diverse groove styles, wide material compatibility, and potential for high – speed, efficient machining, are essential tools in modern turning operations. By understanding how groove styles influence performance, matching inserts to the right materials, and optimizing cutting speeds, machinists can achieve superior results in terms of productivity and part quality.