Carbide-Tipped T-Slot End Mills: Precision Milling for Industrial-Grade T-Slots

In the world of metalworking and CNC machining, few tools deliver the precision and durability needed for T-slot milling like carbide-tipped T-slot end mills (often called “carbide T-mills” for short). These specialized cutters are engineered to carve precise T-shaped grooves into metal, aluminum, and even hardened steel—critical for creating workholding fixtures, machine tables, and modular assembly systems. Whether you’re a CNC machinist producing aerospace components or a metal fabrication shop building custom jigs, understanding how carbide T-slot mills work, their advantages, and best practices for use is key to achieving flawless T-slots every time.

This guide dives into the anatomy of carbide T-slot end mills, their applications, material science, and pro tips for avoiding common milling mistakes. By the end, you’ll know exactly why these tools are indispensable for industrial T-slot machining—and how to choose the right one for your next project.

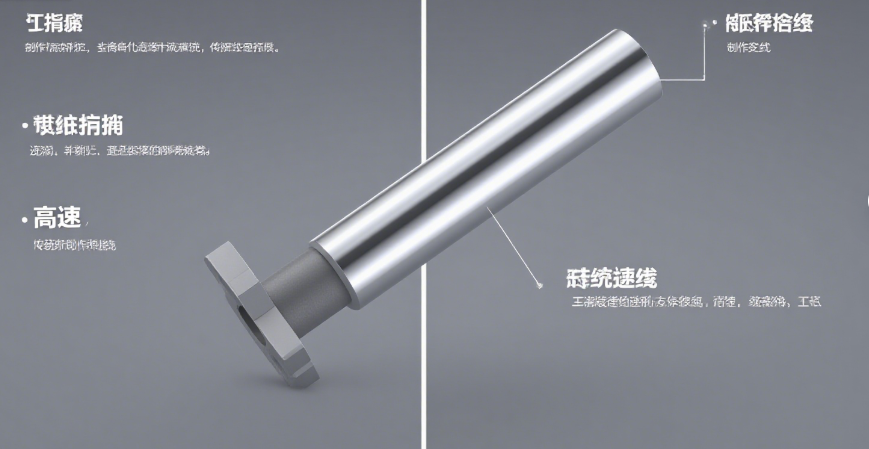

What Are Carbide-Tipped T-Slot End Mills?

A carbide-tipped T-slot end mill is a cutting tool designed to mill T-shaped slots in metal workpieces. Unlike standard end mills (which cut straight or contour slots), T-slot mills have a unique geometry:

- A straight or helical flute body (to remove chips)

- A carbide-tipped cutting head with a wider “T” profile (to shape the slot’s undercut)

- A sturdy shank (to handle high torque in CNC machines)

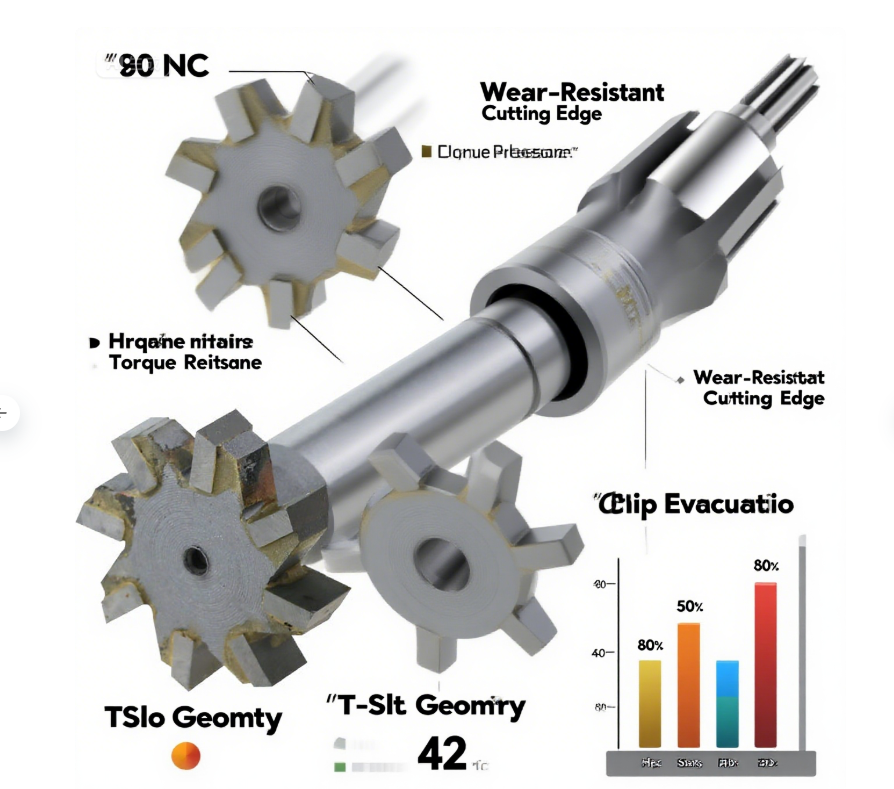

Key Design Features

- Carbide Tips: Made from tungsten carbide (hardness ~90 HRC), these tips resist wear even when milling hardened steel (up to 50 HRC).

- T-Slot Geometry: The cutter’s head has a wider diameter at the base (the “T” undercut) and a narrower shank—this matches the T-slot’s shape (a narrow top slot leading to a wider bottom channel).

- Flute Design: Helical flutes (3–4 flutes) for chip evacuation; straight flutes for simpler, lower-torque applications.

Why Carbide? The Science of Wear Resistance

Tungsten carbide is a ceramic-metal composite (WC + Co binder) with:

- Hardness: ~3x harder than high-speed steel (HSS), so it retains sharp edges longer.

- Heat Resistance: Maintains hardness at 1,000°C+ (vs. HSS, which softens at 600°C).

- Impact Resistance: Carbide-tipped tools (vs. solid carbide) balance durability and cost—ideal for industrial milling.

Applications: Where Carbide T-Slot Mills Shine

Carbide-tipped T-slot end mills are the go-to tool for machining T-slots in:

1. Machine Tool Tables

- Use Case: Milling T-slots in cast iron or steel tables for workholding clamps (e.g., Kurt vises).

- Challenge: Hard, abrasive materials (cast iron has embedded graphite flakes).

- Solution: Carbide tips withstand abrasion—HSS tools would dull in minutes.

2. Modular Fixturing Systems

- Use Case: Creating T-slots in aluminum or steel fixtures for quick-change tooling.

- Challenge: Needing tight tolerances (±0.01mm) for clamp fitment.

- Solution: Carbide’s precision cutting ensures slot dimensions stay within tolerance.

3. Aerospace Components

- Use Case: Milling T-slots in titanium or Inconel parts for structural ribs.

- Challenge: High-temperature alloys that generate extreme heat during cutting.

- Solution: Carbide’s heat resistance prevents tool failure—even at 1,000°C.

4. Welding & Fabrication Jigs

- Use Case: Cutting T-slots in mild steel jigs for securing welding fixtures.

- Challenge: Variable material hardness (welded parts have uneven hardness).

- Solution: Carbide tips handle hardness variations better than HSS.

Materials They Can Mill (and Can’t)

| Material | Hardness (HRC) | Carbide T-Mill Compatibility | Notes |

|---|---|---|---|

| Mild Steel | 10–25 | ✔️ (Alloyed carbide) | Fast feeds, low wear |

| Alloy Steel | 30–50 | ✔️ (Premium carbide) | Use coolant to reduce heat |

| Cast Iron | 20–35 | ✔️ (Coated carbide) | Graphite flakes accelerate wear—coated tips last longer |

| Titanium/Inconel | 35–55 | ✔️ (Ultra-hard carbide) | Slow feeds, high coolant |

| Aluminum | 5–15 | ❌ (Overkill—use HSS) | Carbide is too hard for soft aluminum (causes chatter) |

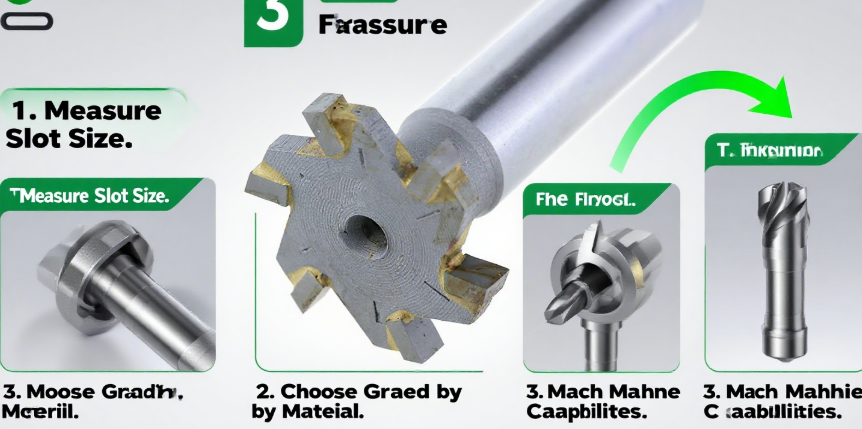

How to Choose the Right Carbide T-Slot End Mill

Selecting the correct T-slot mill depends on three factors: workpiece material, slot dimensions, and machine capabilities.

1. Match the T-Slot Size

T-slot dimensions are standardized (e.g., ISO 2982, ANSI B18.3). Choose a mill where:

- The tip width matches the T-slot’s top slot width (e.g., 10mm top slot → 10mm tip).

- The undercut depth matches the T-slot’s bottom channel (e.g., 6mm undercut → 6mm tip undercut).

2. Select Carbide Grade

- General Purpose (GP): For mild steel, cast iron (alloyed carbide, e.g., WC-6%Co).

- Premium (P): For alloy steel, stainless steel (coated carbide, e.g., TiAlN coating).

- Ultra-Hard (UH): For titanium, Inconel (nanostructured carbide, e.g., WC-10%Co with TiN coating).

3. Consider Flute Design

- Helical Flutes: Best for CNC machines—spiral flutes pull chips out, reducing re-cutting.

- Straight Flutes: For manual milling machines—simpler, lower cost, but slower chip evacuation.

4. Check Shank Compatibility

- Weldon Shank: Flat-sided shank for high-torque CNC mills (prevents slipping).

- Round Shank: For manual mills—requires a collet or chuck with good grip.

Best Practices for Milling T-Slots with Carbide Tools

Even the best tool fails without proper technique. Follow these steps for flawless T-slots:

1. Pre-Mill the Top Slot

- Why: T-slot mills can’t start a slot from scratch—use a standard end mill to cut the top slot first (width = T-mill tip width, depth = T-slot depth).

- How: For a 10mm T-slot, mill a 10mm-wide, 6mm-deep top slot with a square end mill.

2. Set Speeds & Feeds

Carbide tools need lower speeds, higher feeds than HSS (to avoid dulling from heat). Use this guide:

| Material | Speed (SFM) | Feed per Tooth (IPT) | Coolant |

|---|---|---|---|

| Mild Steel | 200–300 | 0.004–0.006” | Flood coolant |

| Alloy Steel | 150–250 | 0.003–0.005” | High-pressure coolant |

| Cast Iron | 250–350 | 0.005–0.008” | Dry (graphite acts as lubricant) |

| Titanium | 50–100 | 0.002–0.003” | Flood coolant |

3. Use Climb Milling (Preferred)

- Climb Milling: The cutter rotates with the workpiece’s feed direction—reduces chatter and tool wear.

- Conventional Milling: Cutter rotates against the feed—more common for manual mills but increases wear.

4. Monitor Chip Evacuation

- Helical Flutes: Chips should flow out smoothly—if chips clog, reduce feed rate or increase coolant pressure.

- Straight Flutes: Pause periodically to clear chips (use air blast or manual cleaning).

5. Inspect Tool Wear

- Signs of Dullness: Chatter marks, burned chips, or increased cutting forces.

- Re-Sharpening: Carbide tips can be re-sharpened 2–3 times (use a diamond wheel)—but only if the shank is undamaged.

Maintenance: Extend Carbide T-Mill Life

Carbide-tipped tools are expensive—protect your investment with these maintenance tips:

1. Clean After Use

- Remove Chips: Use a brass brush to clean flutes (steel brushes damage carbide).

- Wipe Coolant: Remove coolant residue with a solvent (prevents corrosion on the steel shank).

2. Store Properly

- Tool Holder: Keep T-mills in a dedicated case or rack—avoid tossing them in a drawer (carbide tips chip easily).

- Climate Control: Store in a dry, temperature-stable environment (humidity causes shank rust).

3. Re-Sharpen Carefully

- Use Diamond Wheels: Only re-sharpen with a diamond grinding wheel (carbide is too hard for aluminum oxide wheels).

- Maintain Geometry: Re-sharpen at the original angle (usually 30–45°) to preserve T-slot profile.

4. Retire Dull Tools

- When to Replace: If re-sharpening doesn’t restore cutting performance, or if the carbide tip is chipped. A chipped tip will cause poor surface finish and damage the workpiece.

Final Thoughts: Carbide T-Slot Mills—The Gold Standard for Precision

For industrial T-slot machining, carbide-tipped T-slot end mills are unmatched in durability and precision. While they cost more than HSS tools, their ability to mill hard materials, maintain tight tolerances, and resist wear makes them a long-term investment for any machining shop.

Remember: Success with T-slot mills hinges on matching the tool to the material, pre-milling the top slot, and following best practices for speeds, feeds, and maintenance. With the right approach, these tools will deliver flawless T-slots for years—turning complex milling tasks into routine operations.

Now, load your carbide T-mill, pre-mill that top slot, and let the tool do the hard work—your perfect T-slot is just a cut away.