Carbide Cutting Tools: The Ultimate Guide to Durability & Precision for Machining Pros

In metalworking, woodworking, and manufacturing—tool performance directly impacts productivity. A dull high – speed steel (HSS) tool might last 10 minutes cutting stainless steel, while a carbide cutting tool handles the same material for 2 + hours without losing sharpness. That’s why carbide tools have become the gold standard for professionals: their unique blend of hardness, heat resistance, and wear resistance solves the biggest pain points of traditional tools—frequent tool changes, inconsistent cuts, and wasted materials.

This guide breaks down everything you need to master carbide cutting tools: from understanding their composition and types to choosing the right tool for your material, optimizing cutting parameters, and extending tool life. By the end, you’ll know how to leverage carbide’s strengths to cut faster, reduce downtime, and improve part quality.

What Are Carbide Cutting Tools, and Why They Outperform Traditional Tools

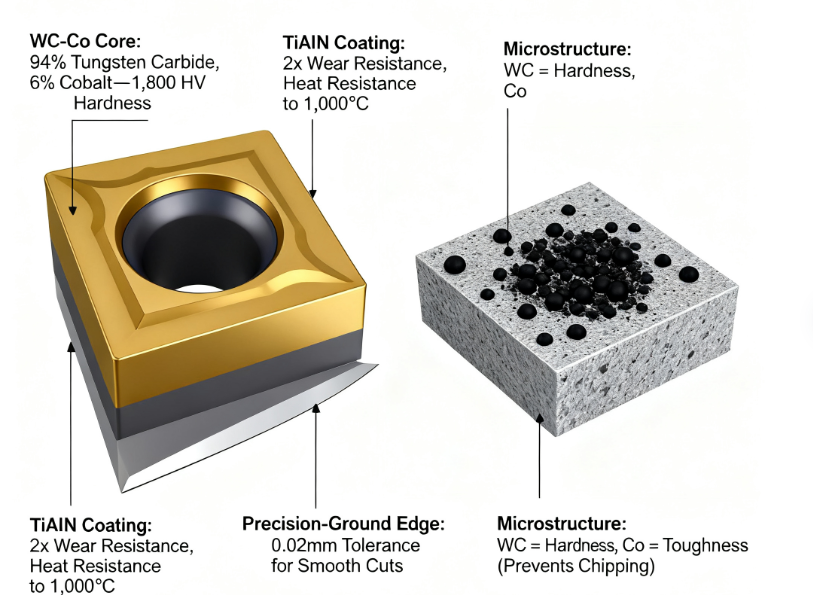

Carbide cutting tools (often called cemented carbide tools) are made from tungsten carbide (WC) powder mixed with a metal binder (usually cobalt, Co) and sintered at high temperatures (1,300–1,600°C). The result is a tool that’s:

- 3x harder than HSS: Tungsten carbide has a Vickers hardness of 1,800–2,200 HV, compared to HSS’s 800–1,000 HV—meaning it resists wear when cutting abrasive materials like cast iron.

- Heat – resistant up to 1,000°C: Unlike HSS (which softens at 600°C), carbide maintains its hardness even at extreme cutting temperatures—critical for high – speed machining (HSM).

- Longer tool life: Carbide tools last 5–10x longer than HSS tools in most applications. For example, a carbide end mill cuts 500 aluminum parts before needing replacement, while an HSS end mill only cuts 50.

Why This Matters for Machinists

Imagine you’re cutting 100 steel brackets with an HSS drill bit: you’d stop 5x to change dull bits, losing 30 minutes of production time. With a carbide drill bit, you finish all 100 brackets in one go—saving time and ensuring every hole has the same precision. That’s the difference carbide makes: consistency and efficiency.

The 5 Most Common Types of Carbide Cutting Tools (And Their Uses)

Carbide tools come in hundreds of designs, but these 5 types cover 90% of machining tasks. Each is optimized for specific cuts and materials:

1. Carbide End Mills (For Milling)

- Design: Cylindrical tools with multiple flutes (2–6) for side milling, face milling, or slotting. Available in square – end (for flat surfaces) or ball – nose (for 3D contours).

- Best For: Cutting metal (steel, aluminum, titanium), plastic, and composite materials. Used in CNC mills and vertical machining centers (VMCs).

- Pro Tip: For aluminum (soft material), use a 4 – flute carbide end mill with a polished flute—reduces chip buildup. For steel (hard material), choose a 2 – flute TiAlN – coated end mill for better chip evacuation.

2. Carbide Drill Bits (For Drilling)

- Design: Tapered or straight – shank bits with a pointed tip and spiral flutes. Carbide twist drills are the most common—ideal for deep holes.

- Best For: Drilling hard metals (stainless steel, alloy steel) and abrasive materials (cast iron). Outperforms HSS drills in high – speed drilling.

- Key Spec: Look for a “split point” (135° angle) for self – centering—avoids wandering on hard materials (e.g., a 135° carbide drill bit drills a 10mm hole in stainless steel 2x faster than a 118° HSS bit).

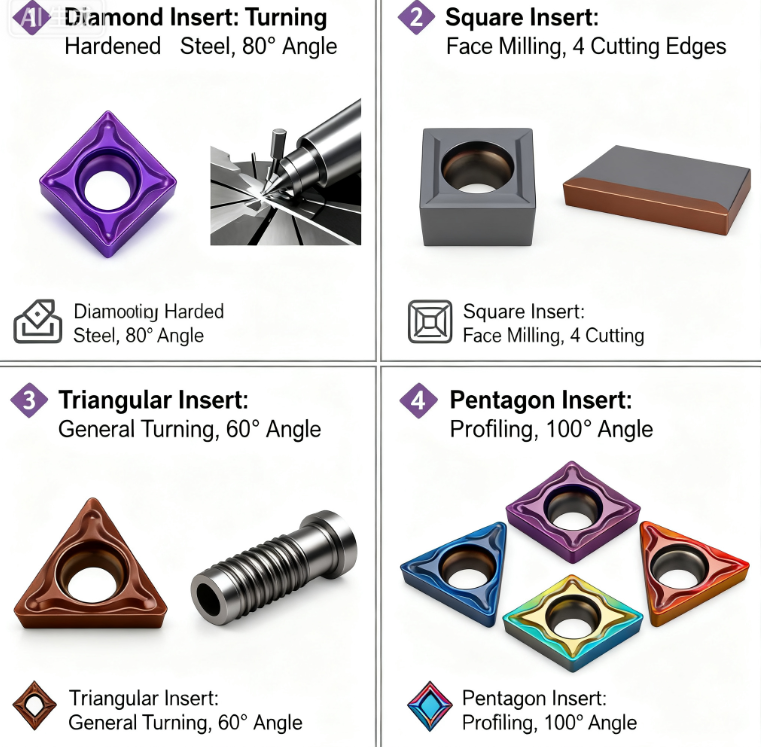

3. Carbide Turning Inserts (For Lathe Work)

- Design: Removable, replaceable carbide tips (shapes: square, triangular, round) clamped to a steel tool holder. Inserts have pre – ground cutting edges and coatings.

- Best For: Turning, facing, and boring on lathes—used for cylindrical parts (e.g., engine shafts, pipes) made of steel, cast iron, or brass.

- Cost – Saver: Instead of replacing the entire tool, just swap the insert (costs $5–$20 vs. $50–$100 for a new solid carbide tool).

4. Carbide Saw Blades (For Cutting Sheets)

- Design: Circular blades with carbide teeth (10–100 teeth) for cutting metal sheets, wood, or plastic. Teeth are brazed to a steel hub for stability.

- Best For: High – volume cutting—e.g., a carbide – tipped metal saw blade cuts 1,000 aluminum sheets before dulling, while a steel blade only cuts 100.

- Tooth Count Tip: Use 60–100 teeth for smooth cuts (e.g., aluminum sheets for electronics) and 10–24 teeth for fast cuts (e.g., thick steel plates).

5. Carbide Burrs (For Deburring/Shaping)

- Design: Small, cylindrical tools with abrasive carbide heads (shapes: cylindrical, conical, ball – nose) for deburring, chamfering, or shaping. Used with die grinders.

- Best For: Cleaning up metal parts (e.g., removing burrs from drilled holes) or shaping wood (e.g., carving intricate details).

- Safety Note: Use a carbide burr at 10,000–20,000 RPM—too slow causes clogging; too fast overheats the tool.

How to Choose the Right Carbide Tool (3 Key Factors)

Choosing the wrong carbide tool leads to poor cuts, short tool life, and wasted money. Focus on these 3 factors to get it right:

1. Match the Tool to the Workpiece Material

Carbide tools are optimized for specific materials—using a tool for soft material on hard metal ruins it. Here’s a quick guide:

| Workpiece Material | Recommended Carbide Tool Type | Coating (If Needed) | Cutting Speed (Reference) |

|---|---|---|---|

| Aluminum (Soft) | 4 – flute end mill, 60 – tooth saw blade | Uncoated or TiCN | 300–500 m/min |

| Steel (Hard) | 2 – flute TiAlN end mill, 135° drill | TiAlN or AlTiN | 100–200 m/min |

| Cast Iron (Abrasive) | Triangular turning insert, burr | TiCN or CrN | 80–150 m/min |

| Titanium (Tough) | Solid carbide drill, 4 – flute end mill | AlTiN or DLC | 30–80 m/min |

- Example: Cutting titanium with an uncoated carbide end mill? It will dull in 5 minutes. Switch to an AlTiN – coated end mill, and it lasts 45 minutes—thanks to AlTiN’s resistance to titanium’s “sticking” behavior.

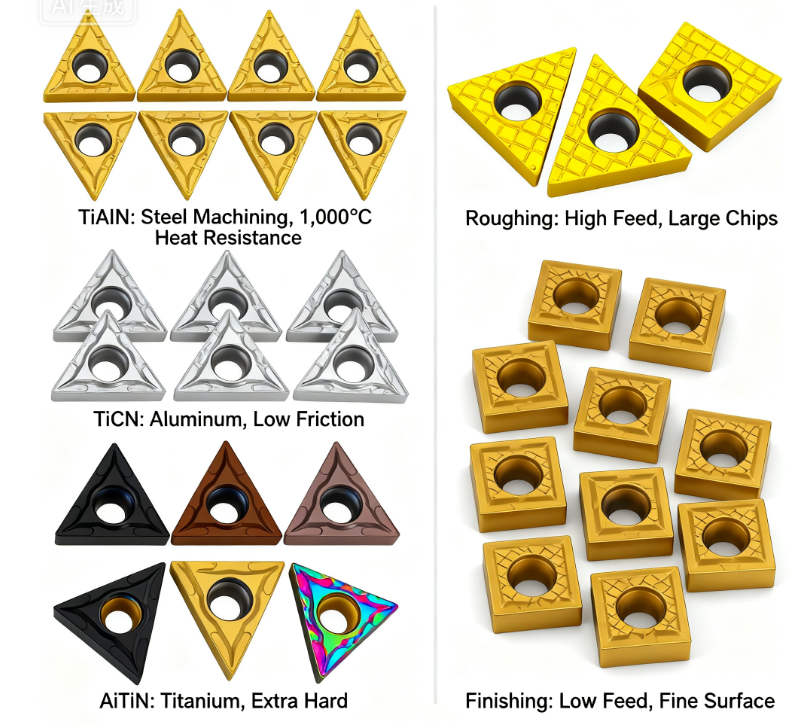

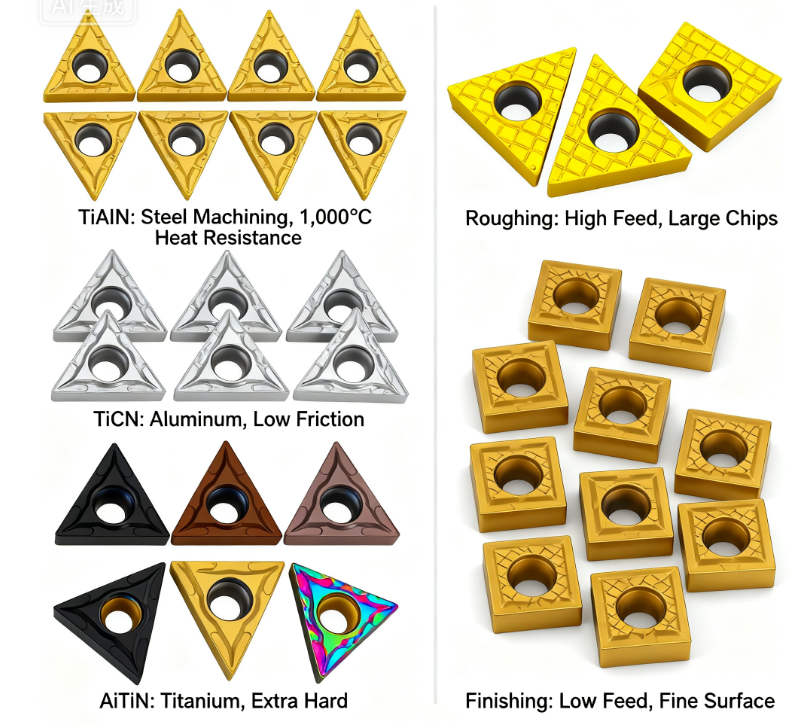

2. Choose the Right Coating

Carbide coatings boost performance by reducing friction and heat. Here are the most common:

- TiAlN (Titanium Aluminum Nitride): Golden color, heat – resistant to 1,000°C. Best for steel, stainless steel, and high – speed machining.

- TiCN (Titanium Carbonitride): Silver – gray, low friction. Ideal for aluminum (prevents chip buildup) and cast iron.

- AlTiN (Aluminum Titanium Nitride): Violet, harder than TiAlN. For tough materials like titanium and Inconel.

- DLC (Diamond – Like Carbon): Black, ultra – low friction. Used for plastic and non – ferrous metals (e.g., copper) to avoid melting.

3. Consider the Cut Type (Roughing vs. Finishing)

- Roughing: Remove large amounts of material quickly. Choose a carbide tool with fewer flutes (2–3) for better chip evacuation (e.g., 2 – flute end mill for roughing steel).

- Finishing: Create smooth, precise surfaces. Use a tool with more flutes (4–6) and a sharp cutting edge (e.g., 4 – flute ball – nose end mill for finishing aluminum parts).

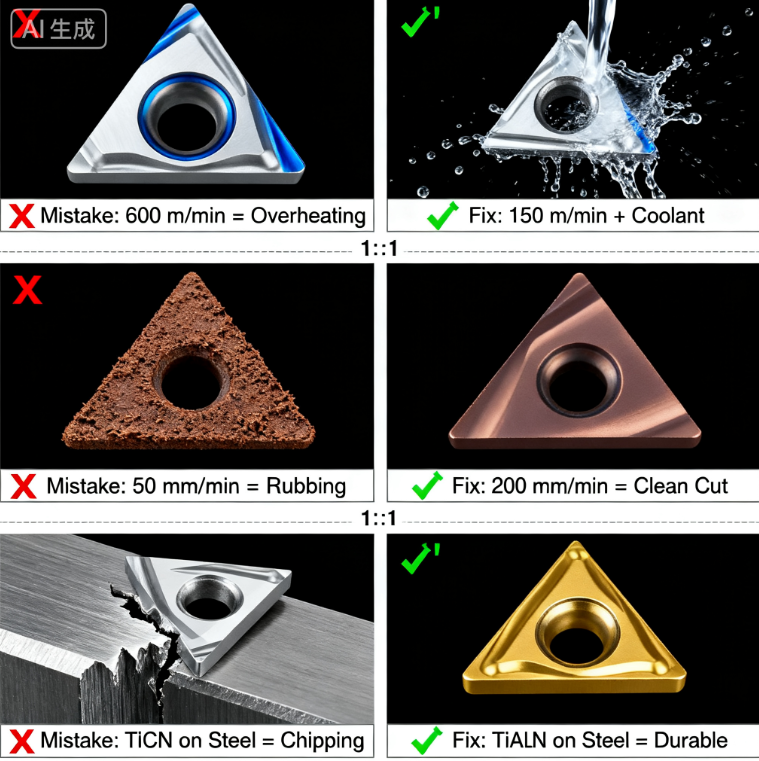

Common Carbide Tool Mistakes (And How to Fix Them)

Even pros make these errors—here’s how to spot and solve them to extend tool life:

1. Cutting Speed Too High (Causes Overheating)

- Sign: Tool turns blue (from heat) or cuts produce burned chips (e.g., black steel chips).

- Why It Happens: Carbide can handle heat, but excessive speed (e.g., 600 m/min for steel) melts the tool’s coating and softens the binder.

- Fix: Reduce speed to the recommended range (e.g., 150 m/min for steel). Use a coolant (flood or mist) to dissipate heat—extends tool life by 30%.

2. Feed Rate Too Low (Causes Rubbing)

- Sign: Tool “squeals” during cutting, or the workpiece has a rough surface (tool marks).

- Why It Happens: A slow feed rate (e.g., 50 mm/min for aluminum) makes the tool rub against the material instead of cutting—dulling the edge.

- Fix: Increase feed rate to the optimal range (e.g., 200 mm/min for aluminum). Use the formula: Feed Rate = RPM × Number of Flutes × Chip Load (e.g., 3,000 RPM × 4 flutes × 0.05 mm = 600 mm/min).

3. Using the Wrong Tool for the Material (Causes Chipping)

- Sign: Tool edge chips or breaks (e.g., a carbide burr for aluminum breaks when used on steel).

- Why It Happens: Soft – material tools have a more fragile edge—using them on hard metal snaps the edge.

- Fix: Match the tool to the material (e.g., use an AlTiN – coated tool for steel, not an uncoated one). For brittle materials (e.g., cast iron), choose a tool with a “negative rake angle” (10–15°) to reduce chipping.

How to Extend Carbide Tool Life (5 Pro Tips)

A quality carbide tool costs $20–$200—extending its life saves money and reduces downtime. Follow these tips:

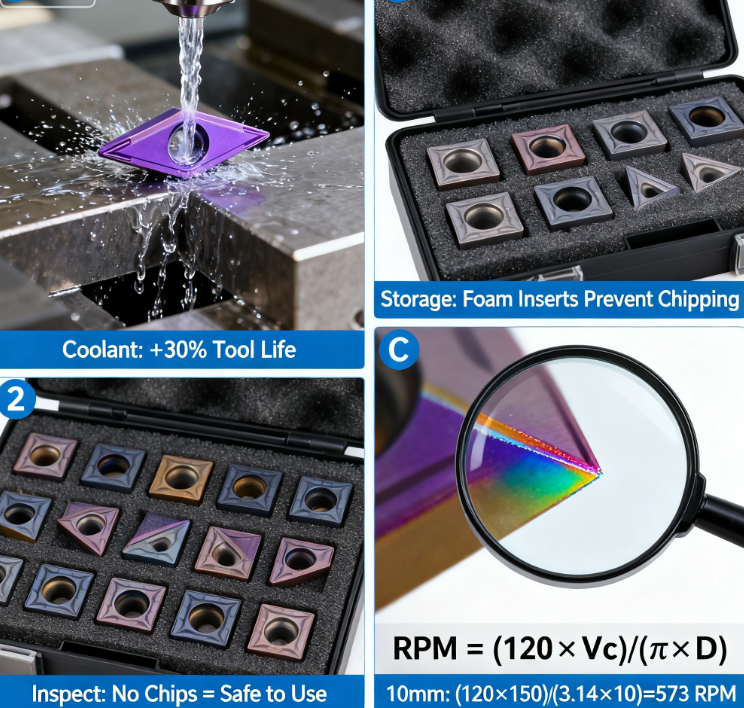

1. Use Coolant (Always)

Coolant reduces heat and friction—critical for carbide tools. For metalworking:

- Flood Coolant: Best for high – speed machining (e.g., milling steel)—covers the tool and workpiece completely.

- Mist Coolant: For tight spaces (e.g., drilling small holes)—mixes coolant with air to reach the cutting zone.

- Dry Cutting: Only for aluminum (if coolant causes chip buildup)—use a TiCN – coated tool to reduce friction.

2. Store Tools Properly

- Keep carbide tools in a dry, temperature – controlled area (15–25°C)—moisture causes rust on steel holders; extreme heat damages coatings.

- Use a tool cabinet with foam inserts (labeled by tool type)—avoids collisions (dropping a carbide end mill can chip the edge).

3. Inspect Tools Before Use

- Check for chipped edges (use a magnifying glass)—a small chip will grow and ruin the tool during cutting.

- Verify the coating is intact—peeling coating means the tool is worn and needs replacement.

4. Optimize Cutting Parameters

Use a machining calculator to find the right speed and feed rate (e.g., for a 10mm carbide end mill in steel: RPM = (120 × Cutting Speed) / π × Diameter = (120 × 150) / 3.14 × 10 ≈ 573 RPM; Feed Rate = 573 × 2 × 0.1 = 114.6 mm/min).

5. Avoid “Tool Shock”

- Lower the tool into the workpiece slowly—sudden contact (e.g., slamming a drill bit into steel) chips the cutting edge.

- For lathe work, use a “ramping” cut (gradually increase depth) instead of full – depth cuts—reduces stress on the insert.

Conclusion

Carbide cutting tools aren’t just “better” than traditional tools—they’re a strategic investment. By choosing the right tool for your material, optimizing cutting parameters, and following maintenance tips, you’ll cut faster, reduce tool changes, and produce higher – quality parts.

Remember: The key to carbide success is matching the tool to the task. A TiAlN – coated end mill for steel won’t work for titanium, and a low – feed rate will waste even the best carbide drill bit. Take 5 minutes to plan your tool selection and parameters—this small step will save you hours of rework, boost your productivity, and help you achieve machining excellence with carbide cutting tools.

Whether you’re a seasoned machinist refining aerospace components or a small – shop operator crafting custom metal parts, carbide tools empower you to push the boundaries of precision and efficiency. Embrace their durability, master their application, and watch as they transform your workflow—turning complex cuts into seamless processes, and raw materials into flawless finished products.

So, the next time you reach for a cutting tool, let carbide be your first choice. It’s not just about getting the job done—it’s about getting it done better, faster, and with results that stand the test of time. Your machining projects deserve the precision and reliability only carbide can deliver.