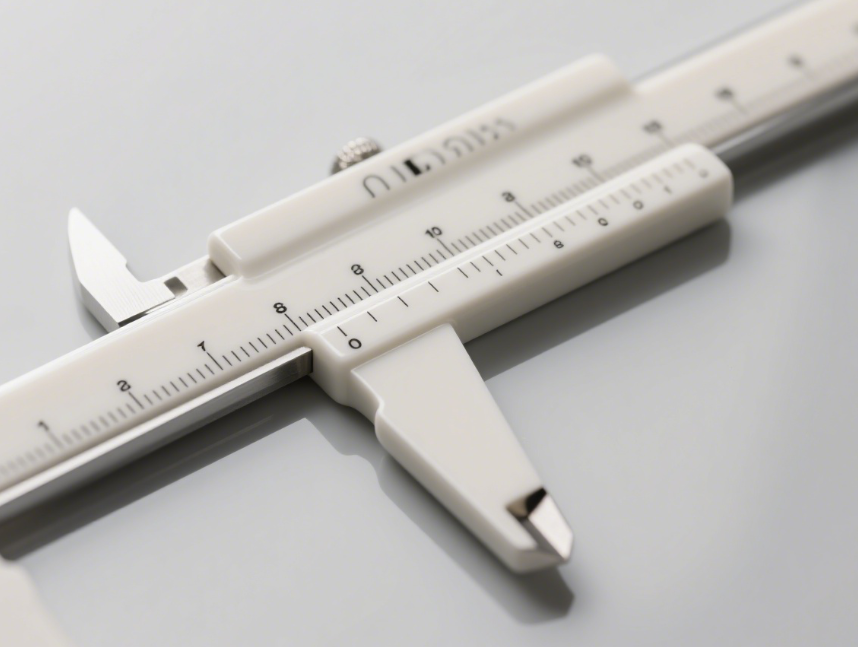

Calipers: The Ultimate Guide to Precision Measurement Tools

Master Accuracy, Selection, and Best Practices for Industrial and DIY Applications

1. Why Calipers Are Non-Negotiable in Precision Work

Calipers are fundamental dimensional measurement tools used across machining, engineering, and manufacturing. Unlike rulers or tape measures, they deliver accuracy within ±0.02mm (±0.001″), making them indispensable for quality control, prototyping, and CNC operations. Their versatility spans four core functions:

- External measurements (e.g., shaft diameters)

- Internal measurements (e.g., hole dimensions)

- Depth gauging (e.g., recessed slots)

- Step measurements (e.g., tiered surfaces) 15.

In CNC machining, calipers verify part conformity to ±0.01mm tolerances—critical for aerospace components or medical implants where deviations cause systemic failures

1.

2. Types of Calipers: Matching Design to Application

A. Digital Calipers

- Accuracy: ±0.02mm with instant LCD readouts

- Key Features: Unit conversion (inch/mm/fraction), data output ports, auto-off

- Best For: High-speed CNC shops, environments requiring rapid measurements 23.

Example: The Kynup Digital Caliper (IP54 splash-proof) offers 0–150mm range, stainless steel construction, and fraction conversions for woodworking/metalworking 3.

B. Vernier Calipers

- Accuracy: ±0.02mm via manual scale alignment

- Key Features: No batteries, durable in oily/dirty conditions

- Best For: Educational settings, workshops needing EMI/RF interference-free tools 59.

C. Dial Calipers

- Accuracy: ±0.02mm with analog needle display

- Key Features: Tactile feedback, resistance to coolant spills

- Best For: Production floors requiring quick visual checks 18.

D. Micrometer Calipers

- Accuracy: ±0.001mm for ultra-fine measurements

- Key Features: Anvil/spindle design for thickness/diameter checks

- Best For: Calibration labs, precision toolmaking 5.

Table: Caliper Type Comparison

| Type | Accuracy | Readout Speed | Durability | Ideal Use Case |

|---|---|---|---|---|

| Digital | ±0.02mm | Instant | Moderate | CNC shops, prototyping |

| Vernier | ±0.02mm | Slow (skill-based) | High | Educational, harsh environments |

| Dial | ±0.02mm | Moderate | High | Production floors |

| Micrometer | ±0.001mm | Slow | Moderate | Calibration, metrology |

3. Mastering Measurement Techniques: 5 Pro Tips

- 1.Calibrate Religiously:

- Close jaws fully and zero digital/dial models. For verniers, align main/vernier scales at zero 67.

- Validate monthly against gauge blocks in ISO-certified labs 10.

- 2.External Dimensions:

- •Place object between outer jaws using light pressure (excessive force causes 0.05mm+ error) 69.

- 3.Internal Dimensions:

- Use inner jaws for holes—ensure parallel alignment to walls. Pro tip: For <10mm holes, use tapered jaw tips 89.

- 4.Depth Gauging:

- Extend the depth rod flush to the surface; lower until it contacts the base 6.

- 5.Avoid Thermal Errors:

- Handle with gloves: Body heat expands metal jaws by 0.01mm/°C. Measure at 20°C (68°F) where possible 10.

4. Caliper Selection: 4 Critical Factors

- 1.Accuracy Needs:

- General workshop: Digital/dial (±0.02mm)

- Micron-level work: Micrometers (±0.001mm) 5.

- 2.Environment:

- Coolant-heavy CNC zones: IP54-rated digitals (e.g., Mitutoyo AOS) or verniers 13.

- 3.Material Compatibility:

- Stainless steel jaws resist wear in metalworking; carbon fiber suits lightweight DIY tasks 210.

- 4.Ergonomics:

- Thumb rollers > slider locks for one-handed use. Example: Mitutoyo 500-196-30’s thumbwheel enables swift adjustments 3.

5. Maintenance: Extending Tool Life

- •Daily: Wipe jaws with acetone; check for burrs 16.

- •Weekly: Lubricate rails with light machine oil (e.g., ISO VG 10) 5.

- •Storage: Keep in protective cases at 40–60% humidity to prevent corrosion 10.

- •Calibration Cycle:

- •Production environments: Bi-weekly

- •Occasional use: Quarterly 710.

Red Flags Requiring Replacement:

- •Jaws don’t zero after adjustment

- •Visible scratches affecting measurements

- •Digital models show erratic readings 7

6. Industry Applications: Where Precision Matters

- Aerospace: Measuring turbine blade thickness (±0.025mm tolerance) with Mitutoyo digitals 3.

- Medical: Verifying bone screw threads at 0.01mm accuracy 1.

- Automotive: Checking piston ring grooves via depth rod measurements 8.

- 3D Printing: Validating dimensional accuracy of prototypes 2.

7. Future Trends: Smart Calipers & Sustainability

- IoT Integration: Bluetooth-enabled calipers (e.g., Mitutoyo) auto-log data to QC software, reducing human error 3.

- Eco-Materials: Recycled stainless steel and biodegradable cases (e.g., Beslands’ carbon fiber models) 2.

- AI-Assisted Calibration: Self-diagnosing tools predicting calibration drift via embedded sensors 10.

Key Takeaways for Your Readers:

- 1.Match caliper type to task: Digitals for speed, verniers for durability, micrometers for extreme precision.

- 2.Calibrate before every critical measurement—thermal drift causes silent errors.

- 3.Upgrade to IP54+ models if working with coolants or dust.

- 4.Adopt a “zero-tolerance” maintenance routine to preserve ±0.02mm accuracy.

Why Publish This?

This guide targets high-intent keywords like “CNC caliper accuracy” or “digital vs vernier caliper,” positioning your blog as a manufacturing authority. Backed by aerospace and automotive use cases, it appeals to professionals seeking actionable data—ideal for driving organic traffic and conversions.