Calipers in Precision Measurement: Usage, Tips, Efficiency, and Longevity

Calipers are indispensable tools in precision measurement, widely used in manufacturing, engineering, and quality control. Their ability to accurately measure dimensions like length, width, depth, and diameter makes them a cornerstone of ensuring product accuracy. Let’s delve into their types, usage methods, tips for efficiency, and ways to extend their lifespan.

Types of Calipers

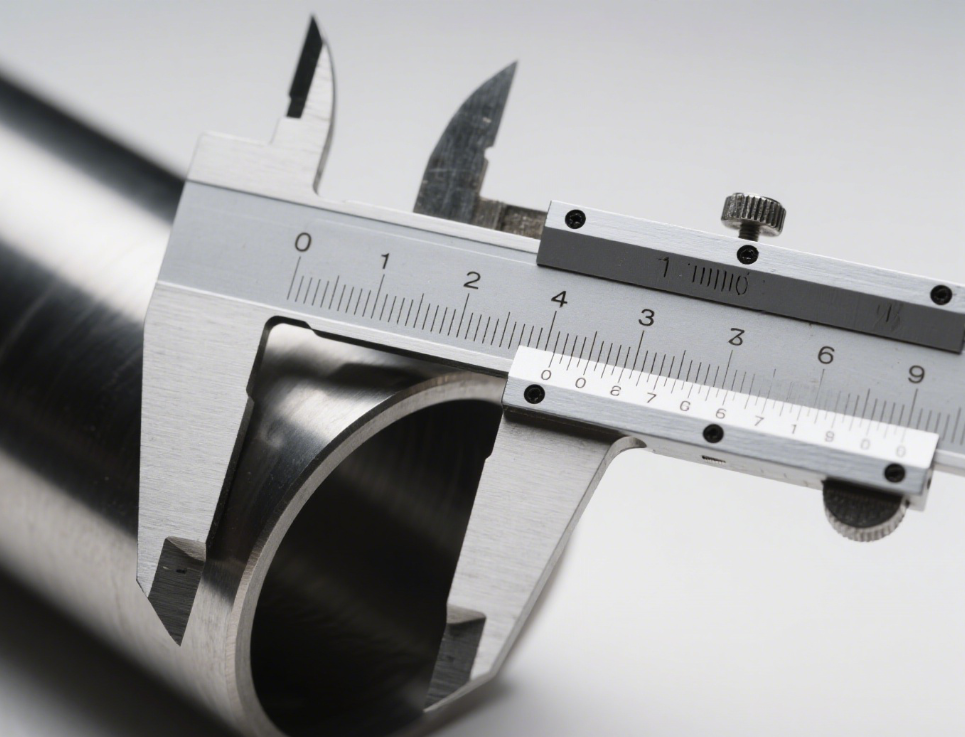

Vernier Calipers

Vernier calipers combine a main scale and a sliding vernier scale, offering precision up to 0.02mm. They are versatile, capable of measuring external dimensions (e.g., the diameter of a rod), internal dimensions (e.g., the bore of a pipe), and depths.

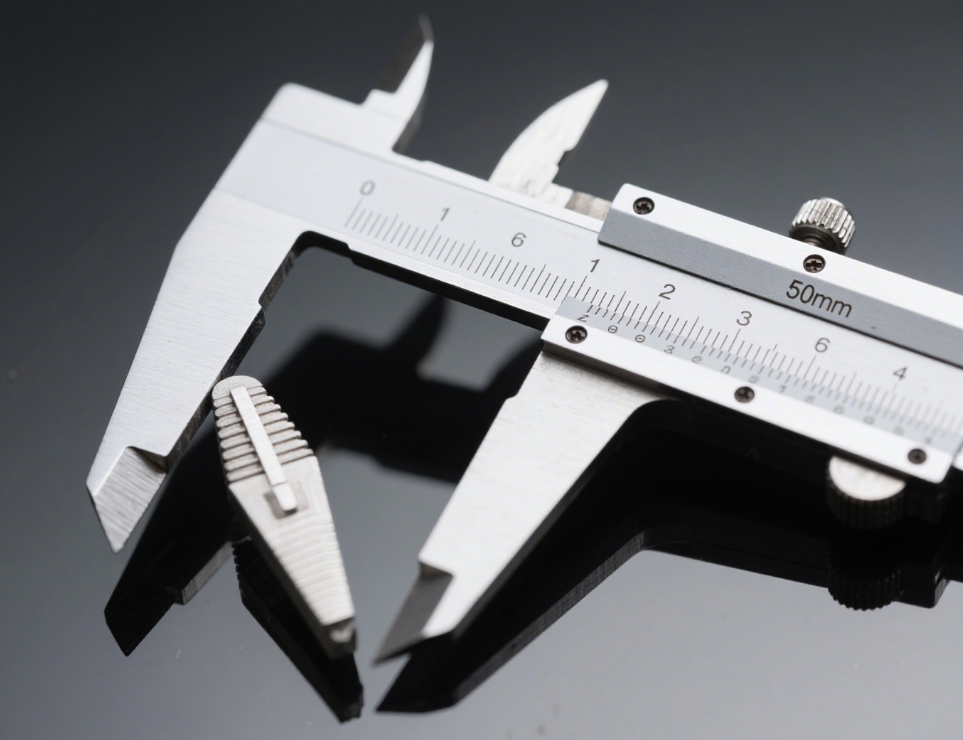

Digital Calipers

Digital calipers feature an electronic display for instant, easy-to-read measurements, with precision often reaching 0.01mm. They eliminate the need for manual interpretation of vernier scales, reducing human error. Many models include functions like zero-setting and unit conversion (mm/inch).

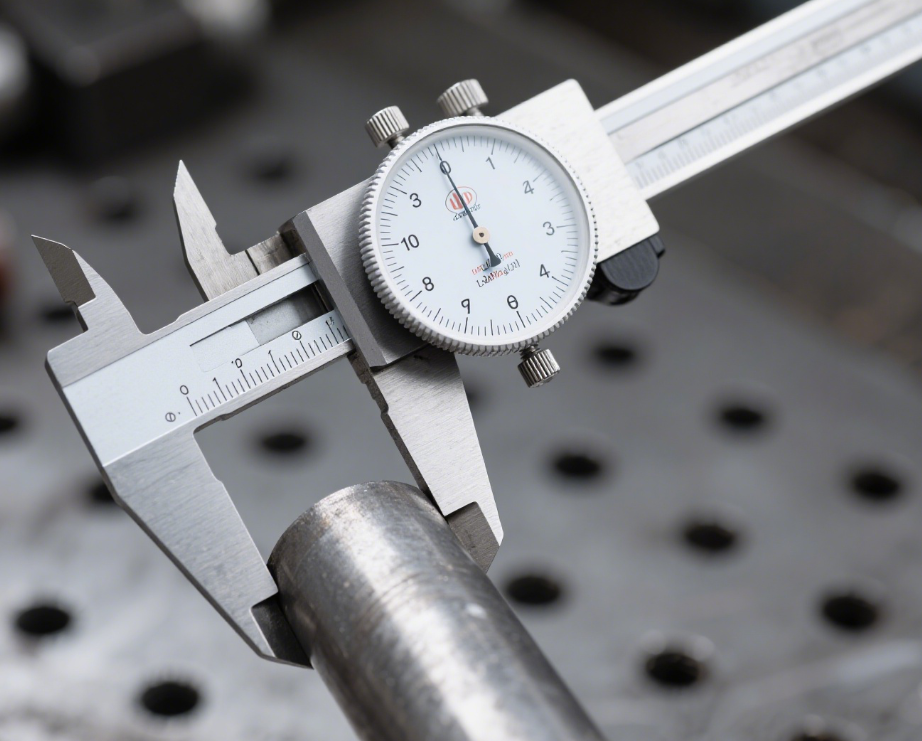

Dial Calipers

Dial calipers use a dial gauge to indicate measurements, blending mechanical reliability with clear readability. They are durable and resistant to dust and moisture, making them suitable for harsh workshop environments.

Proper Usage Methods

Measuring External Dimensions

- Open the caliper jaws and place the object between them, ensuring the jaws are perpendicular to the surface.

- Gently close the jaws until they make light contact with the object—avoid excessive force, which can distort measurements or damage the caliper.

- Lock the slider using the locking screw and read the measurement.

Measuring Internal Dimensions

- Insert the lower jaws into the opening (e.g., a hole or slot) and expand them until they touch the inner walls.

- Ensure the jaws are aligned parallel to the opening’s axis for accurate results.

- Lock the slider and read the measurement, noting that internal measurements often require adding the jaw thickness (check the caliper’s specifications).

Measuring Depth

- Place the base of the caliper firmly on the top surface of the object.

- Extend the depth rod into the cavity until it touches the bottom.

- Hold the caliper steady, lock the slider, and read the depth from the scale or display.

Tips for Higher Efficiency

- Pre-Measurement Checks: Clean the caliper jaws and the object’s surface to remove debris, which can skew measurements. Zero the caliper (close jaws for external, extend depth rod fully for depth) before use.

- Batch Measurement: For multiple identical parts, set the caliper to the target dimension and use it as a go/no-go gauge—quickly checking if parts fall within tolerance without reading exact values each time.

- Leverage Digital Features: Use the zero-setting function on digital calipers to measure deviations from a reference point, speeding up comparative measurements.

Extending Caliper Lifespan

- Avoid Misuse: Never use calipers as tools to pry, scratch, or tighten objects—this can bend jaws or damage scales.

- Clean and Lubricate: After use, wipe the caliper with a clean, dry cloth. Periodically apply a light machine oil to sliding parts to prevent rust and ensure smooth movement.

- Proper Storage: Store calipers in a protective case when not in use, away from moisture, dust, and extreme temperatures. Avoid dropping or stacking heavy objects on them.

- Regular Calibration: Have calipers calibrated annually (or as per industry standards) to ensure measurement accuracy. Even minor wear can affect results over time.

Calipers are precision instruments that reward careful use and maintenance. By mastering their operation, adopting efficient techniques, and protecting them from damage, you can rely on their accuracy for years, ensuring consistent quality in your work.