12

9 月

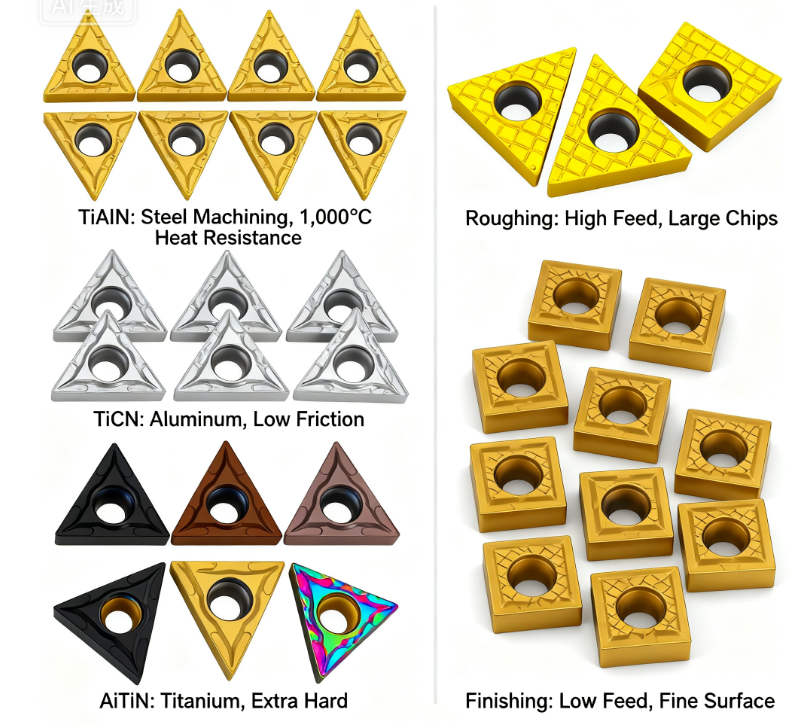

Carbide Cutting Tools: The Ultimate Guide to Durability & Precision for Machining Pros

-

By

yundic

- 0 comments

In metalworking, woodworking, and manufacturing—tool performance directly impacts productivity. A dull high - speed steel (HSS) tool might last 10 minutes cutting stainless steel, while a carbide cutting tool handles the...

12

9 月

Depth Gauges 101: The Ultimate Guide to Accurate Depth Measurement for Professionals & DIYers

-

By

yundic

- 0 comments

In machining, woodworking, automotive repair, or even home DIY projects—precise depth measurement is non-negotiable. Whether you’re drilling a 5mm deep hole in a circuit board, checking the depth of a engine cylinde...

12

9 月

Mastering Face Mills: Your Comprehensive Guide to Precision Machining

-

By

yundic

- 0 comments

In the world of metalworking and machining, achieving flawless, flat surfaces is often the difference between a product that functions optimally and one that falls short. Whether you're working on a high - performance en...

12

9 月

The Ultimate Guide to Measuring Tools: Precision Instruments for Every Workshop

-

By

yundic

- 0 comments

In machining, woodworking, manufacturing, or even DIY projects—accurate measurements are the difference between a perfect fit and a failed part. A 0.01mm error in a bearing housing can cause friction and premature wear; ...

12

9 月

Essential Machining Tools: A Complete Guide for Pros & Hobbyists

-

By

yundic

- 0 comments

In metalworking, woodworking, or manufacturing—having the right machining tools isn’t just about efficiency: it’s about turning raw materials into precise, high-quality parts. From drilling holes to measuring tiny tolera...

12

9 月

Drill Bits: The Ultimate Guide to Choosing & Using the Right Bit for Every Material

-

By

yundic

- 0 comments

In woodworking, metalworking, construction, or even home repairs—drill bits are the foundation of any drilling task. But with dozens of bit types (twist, spade, masonry) and materials (HSS, carbide, cobalt), choosin...

11

9 月

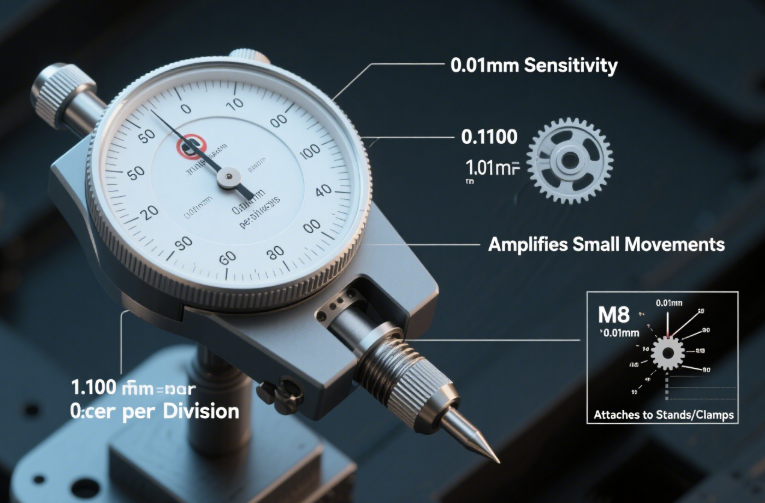

Dial Indicators & Stands: The Dynamic Duo for Precision Measurement

-

By

yundic

- 0 comments

In machining, automotive repair, or manufacturing quality control—where a 0.01mm deviation can ruin a part—dial indicators paired with the right stand aren’t just tools: they’re precision partners. A dial indicator ...

11

9 月

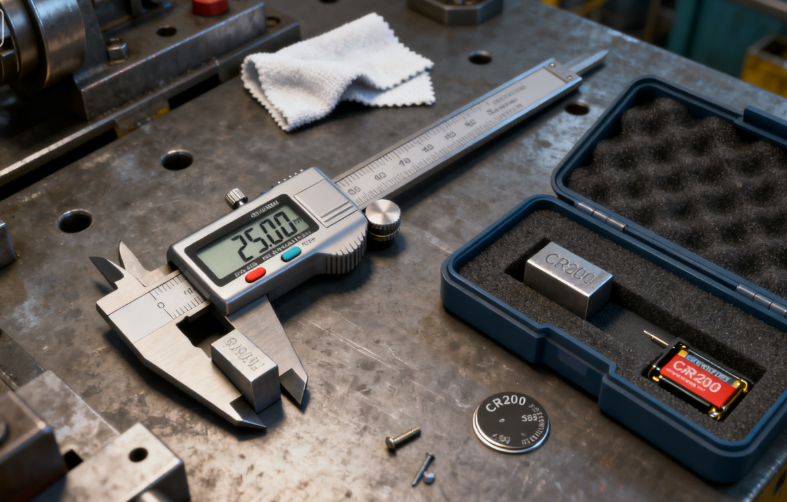

Digital Calipers: The Ultimate Guide to Precision Measurement for Pros & DIYers

-

By

yundic

- 0 comments

In the world of measurement—whether you’re a machinist checking part tolerances, a jeweler sizing gemstones, or a DIYer building a custom project—digital calipers have replaced traditional vernier calipers as the go...

11

9 月

Circular Cold Saw Blades: The Ultimate Guide to Clean, Cool Metal Cutting

-

By

yundic

- 0 comments

In metal fabrication—whether you’re cutting rebar for construction, stainless steel tubes for plumbing, or aluminum extrusions for automotive parts—circular cold saw blades stand out as the gold standard for precision an...

11

9 月

Mastering Milling Cutters: A Comprehensive Guide for Machining Success

-

By

yundic

- 0 comments

The Basics of Milling Cutters

What Exactly is a Milling Cutter?

A milling cutter is a rotary cutting tool used in milling machines to remove material from a workpiece. Unlike a drill bit, which primarily makes ho...

04

9 月

Dial Indicators: Fix Common Measurement Headaches & Boost Precision (Pro Tips Inside)

-

By

yundic

- 0 comments

If you’ve ever spent hours machining a part, only to find it doesn’t fit because of a tiny alignment error—or struggled to diagnose why a machine vibrates nonstop—you know the frustration of imprecision. For machinists, ...

04

9 月

Dial Indicators: The Ultimate Guide to High-Precision Measurement for Machinists & DIYers

-

By

yundic

- 0 comments

In the world of machining, woodworking, and mechanical repair, precision isn’t just a goal—it’s a requirement. A 0.01mm (0.0005-inch) deviation can turn a perfectly fitting part into a useless scrap, or a smoothly runnin...

Load more posts

Loading...