Calipers 101: From Ancient Origins to Modern Precision—Everything You Need to Know

1. Introduction to Calipers

- Definition and Basic Function: Calipers are ruler – like measuring instruments with a graduated scale and a movable head equipped with a fixed jaw and a sliding jaw. They are used to accurately measure the internal and external size of objects, as well as depth. For example, in a car repair shop, calipers are essential for measuring various components such as the diameter of pistons, the thickness of brake discs, and clearances.

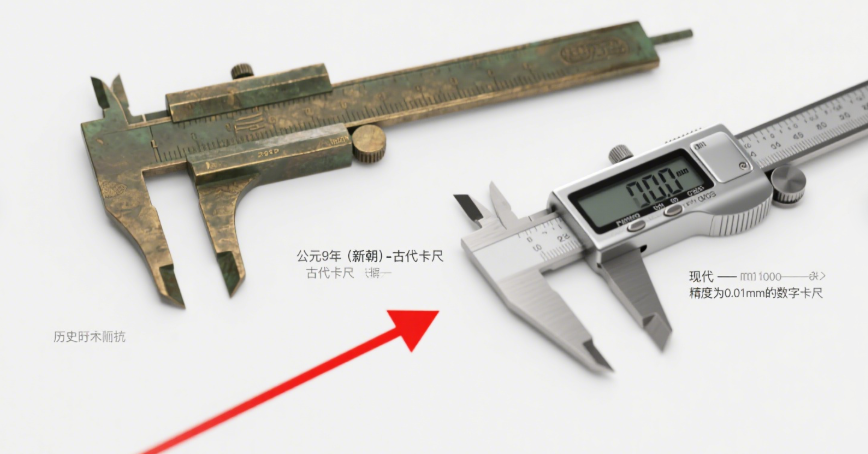

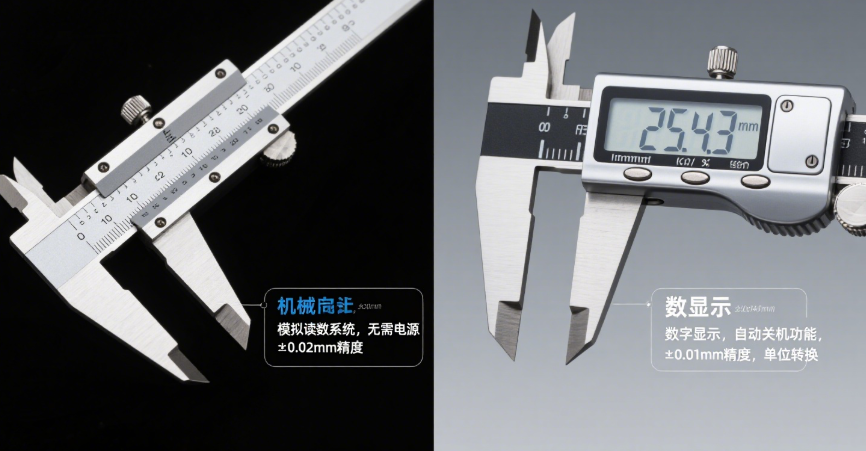

- Historical Background: The idea of the caliper being used as a tool for measurement has been dated back to at least 9 AD during the Xin Dynasty in China. The vernier caliper, which is commonly used in industry, provides a precision to 0.01 mm.

2. Types of Calipers

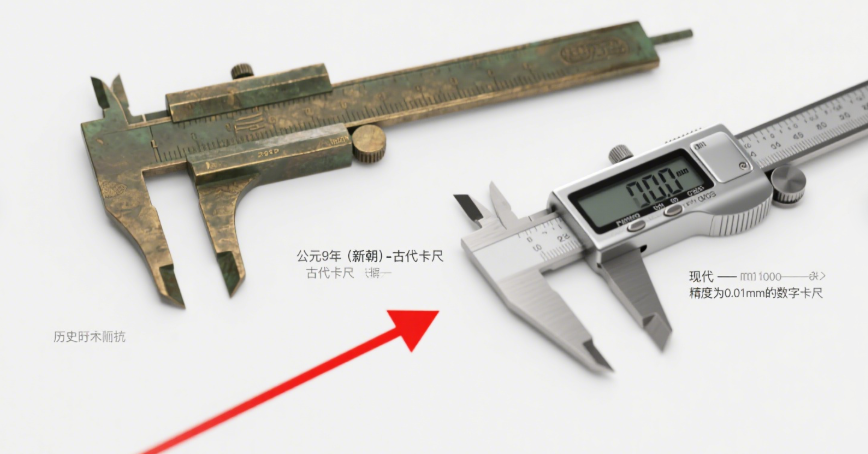

- Mechanical Calipers: Mechanical calipers are the most commonly found type. They are usually made of stainless steel, and some plastic models with a metal rod also exist. They can be used to carry out internal, external, and depth measurements accurately. For example, vernier calipers have a main scale and a vernier scale, and by aligning the scales, the measurement can be read.

- Digital Calipers: Digital calipers are equipped with digital readers, which have the advantage of being error – free and can easily switch between different measurement units such as centimeters and inches. Some digital calipers also contain an inductive linear encoder, which allows them to perform well in the presence of contamination such as coolants.

3. How to Use Calipers Correctly

- Measurement Steps: First, position the tool around the object you want to measure, ensuring that the jaws are aligned with the opposite surfaces of the object. Then, check that the fixed jaw is in firm contact with one side of the object, and slide the movable jaw towards the other side until it is in firm contact with the opposite surface. If using an analogue calliper, align the graduated scale with the sliding ruler and note the measurement on the scale. If using a digital calliper, the reading is displayed directly on the digital display.

- Precautions: The accuracy of a caliper can be affected by the operator’s ability to read and apply proper pressure to the jaws. It is important to regularly calibrate calipers to ensure they remain accurate over time. For example, before using, a visual examination should be carried out to check for any damage or wear on the jaws and the scale.

4. Applications of Calipers in Different Industries

- Manufacturing Industry: In the manufacturing of mechanical parts, calipers are used to measure the dimensions of components to ensure they meet the design requirements. For example, in the production of engine parts, calipers are used to measure the inner diameter of cylinders, the thickness of piston rings, etc.

- Aerospace Industry: In aerospace manufacturing, where high – precision components are required, calipers play a crucial role. They are used to measure the thickness of aircraft skin, the diameter of fasteners, and the dimensions of complex – shaped parts.

- Automotive Industry: As mentioned before, in the automotive industry, calipers are used for measuring various components related to the engine, brakes, and suspension systems to ensure the performance and safety of vehicles.

5. Maintenance and Calibration of Calipers

- Maintenance: After use, calipers should be cleaned to remove any dirt, debris, or lubricant from the jaws and the scale. They should be stored in a dry and protected place to prevent rust and damage. For example, they can be placed in a dedicated caliper case or hung on a wall – mounted rack.

- Calibration: Calibration is an important step to ensure the accuracy of calipers. It usually involves comparing the caliper’s measurement results with a known standard, such as a gauge block. If there is a deviation, the caliper needs to be adjusted or repaired.