Measuring Tools in Hardware: The Unsung Heroes of Precision

In hardware manufacturing, woodworking, or metalworking, “close enough” never cuts it—measuring tools (or “gauges”) are the backbone of turning raw materials into precise, functional parts. From a simple tape measure for DIY projects to a high-precision micrometer for aerospace components, these tools come in a stunning diversity of types, each engineered to measure specific dimensions: length, angle, depth, surface smoothness, or even internal gaps.

What makes 量具 (measuring tools) so critical? A 0.1mm error can turn a perfectly fitting bolt into a useless scrap, or a misaligned angle can ruin an entire furniture frame. This blog explores the full spectrum of hardware measuring tools, their unique strengths, how to use them correctly, and why maintenance matters—with data and visuals to make precision simple.

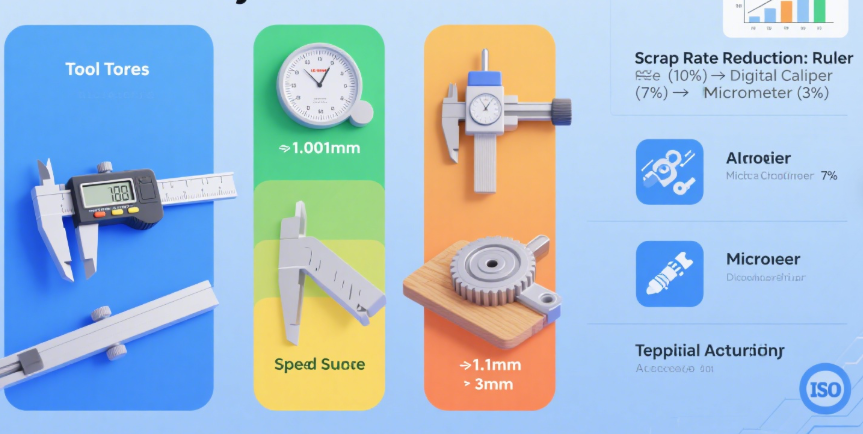

1. The Diverse World of Measuring Tools: By Function

Measuring tools are grouped by what they measure. Understanding this 分类 (classification) helps you pick the right tool for the job, avoiding guesswork and waste.

a. Linear Measuring Tools: For Length, Width, and Depth

Linear tools measure straight dimensions—think “how long is this board?” or “how thick is this metal sheet?” They’re the most common 量具 in any workshop:

i. Calipers (Vernier & Digital)

Calipers are the gold standard for small, precise linear measurements (0–150mm typical range).

- Vernier Calipers: A manual tool with two scales (main + vernier) for accuracy up to 0.02mm. No batteries needed, making it reliable for outdoor or remote work—but it requires practice to read.

- Digital Calipers: A modern upgrade with an LCD screen, showing readings in mm/inch (switchable) with 0.01mm accuracy. Many have a “hold” function to lock measurements and a data port for recording.

- Best For: Measuring small parts (screws, washers), internal holes (e.g., a bearing housing), or external diameters (e.g., a steel shaft).

ii. Micrometers (Outside & Inside)

Micrometers take precision further—ideal for ultra-small, tight-tolerance measurements (down to 0.001mm).

- Outside Micrometers: Measure external dimensions (e.g., the thickness of a metal foil or the diameter of a needle).

- Inside Micrometers: Reach into holes or gaps to measure internal diameters (e.g., the inside of a pipe or a nut’s thread).

- Pro Tip: Micrometers are sensitive to temperature—hold them by the insulated handle (not the metal frame) to avoid heat transfer altering readings.

iii. Tape Measures & Rulers

For larger, less precise measurements (1mm accuracy), tape measures and rulers are indispensable:

- Tape Measures: Retractable, flexible (3–8m long) for measuring boards, furniture, or room dimensions. Look for “double-sided” markings (mm on one side, inches on the other) and a magnetic hook for hands-free use.

- Steel Rulers: Rigid (15–60cm long) for straight-line measurements on flat surfaces (e.g., marking a cut line on plywood).

b. Angle Measuring Tools: For Perfect Angles

Angles are just as critical as length— a 90° corner for a bookshelf or a 45° miter cut for a picture frame won’t work if mismeasured.

i. Speed Square

A triangular, lightweight tool (15–30cm) for quick angle markings:

- Measures 90° (right angles), 45° (miter cuts), and 30°/60° (triangular joints).

- Doubles as a straightedge for marking cut lines on wood or metal.

- Best For: DIY projects (building shelves, cutting trim) and on-the-spot angle checks.

ii. Protractor (Manual & Digital)

Protractors measure precise angles (0–180°) for more complex work:

- Manual Protractors: A semicircular tool with degree markings (1° accuracy) for drawing or checking angles (e.g., a 120° angle on a wooden bracket).

- Digital Protractors: Electronic tools with 0.1° accuracy and a digital display—ideal for industrial work (e.g., checking the angle of a CNC-machined part).

iii. Bevel Protractor

A heavy-duty tool for measuring angles on irregular surfaces (e.g., the angle of a pipe or a welded joint). It has a adjustable blade that locks into place, making it perfect for metalworking.

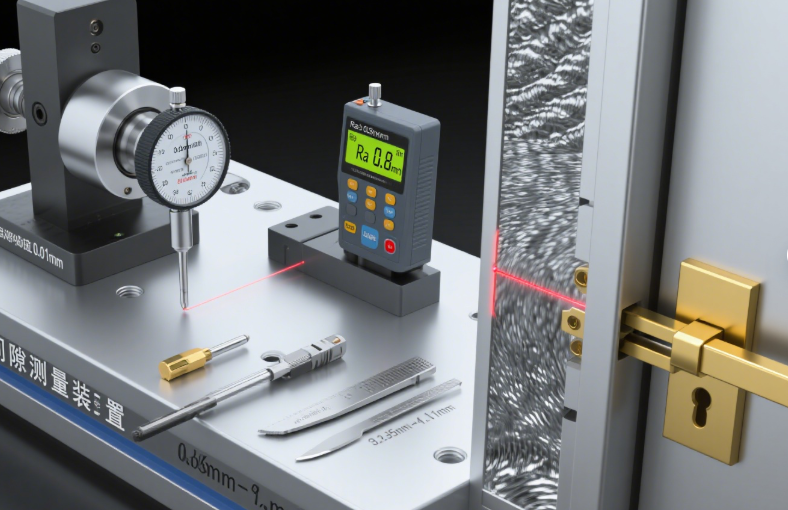

c. Surface & Precision Measuring Tools: For Smoothness and Flatness

Even if dimensions are correct, a rough or uneven surface can ruin a part—these tools check surface quality and tiny deviations:

i. Dial Indicators

A tool with a small probe and a rotating dial (0.01mm accuracy) that measures tiny movements:

- Checks “runout” (how much a rotating part wobbles, e.g., a bent shaft).

- Verifies flatness (e.g., if a metal plate is warped) or alignment (e.g., if a CNC machine’s bed is level).

- Mounted on a magnetic base for hands-free use.

ii. Surface Roughness Tester

A high-tech tool for measuring how smooth a surface is (called “Ra” value, in μm):

- Ra 0.8μm: Smooth enough for painting or staining wood.

- Ra 0.2μm: Ultra-smooth for precision parts (e.g., engine bearings).

- Best For: Industrial manufacturing (aerospace, automotive) where surface finish affects performance.

iii. Feeler Gauges

A set of thin, flexible metal strips (0.02–1mm thick) for measuring small gaps:

- Checks if two surfaces are flush (e.g., a door hinge gap) or if a bearing has the right “play” (looseness).

- Pro Tip: Use the thinnest strip that fits the gap—stack strips for larger gaps (e.g., 0.05mm + 0.1mm = 0.15mm gap).

2. Key Data: How Accuracy & Material Affect Performance

Not all measuring tools are equal—accuracy, material, and price vary widely. Here’s a quick comparison to help you choose:

| Tool Type | Accuracy | Best For | Material (Tool Body) | Price Range |

| Vernier Caliper | 0.02mm | Small parts (metal/wood) | Stainless Steel | 15–50 |

| Digital Caliper | 0.01mm | Precision metalwork | Stainless Steel/Plastic | 20–80 |

| Outside Micrometer | 0.001mm | Ultra-precise metal parts | Stainless Steel | 30–120 |

| Speed Square | 1° | DIY woodworking | Aluminum | 5–20 |

| Digital Protractor | 0.1° | Industrial angles | Aluminum/Steel | 40–150 |

| Dial Indicator | 0.01mm | Runout/flatness checks | Steel | 50–200 |

Real-World Impact: Using a 0.1mm-accuracy digital caliper instead of a 1mm-accuracy ruler reduces scrap rates by 30% in small-part manufacturing—saving $1,200/year for a small workshop.

3. Pro Tips: Calibration, Maintenance, and Safety

Even the best measuring tools fail without proper care. Follow these rules to keep them accurate:

a. Calibrate Regularly

- Why: Tools drift over time (e.g., a micrometer’s thread wears down, causing 0.005mm errors).

- How: Use “gauge blocks” (standardized metal blocks with known dimensions, e.g., 25.000mm) to check accuracy. For industrial use, calibrate every 6 months; for DIY, once a year.

- Consequence of Skipping: Uncalibrated tools cause bad parts—e.g., a 0.01mm error in a bearing measurement leads to premature failure.

b. Maintain Carefully

- Clean After Use: Wipe metal tools with a dry cloth to remove oil, dust, or wood chips—moisture causes rust. For calipers/micrometers, use a small amount of machine oil on moving parts.

- Store Properly: Keep tools in padded cases (e.g., caliper cases) to avoid dings—even a small scratch on a micrometer’s anvil ruins accuracy.

- Avoid Abuse: Don’t drop tools or use them as hammers— a digital caliper’s LCD screen cracks easily.

c. Use Safely

- Wear Gloves: When using feeler gauges or sharp tools (e.g., steel rulers), gloves prevent cuts.

- Stabilize Workpieces: Clamp parts to a workbench before measuring—unstable parts lead to wrong readings.

Final Thought: Precision Starts with the Right Tool

Measuring tools are more than just “gadgets”—they’re investments in quality. Whether you’re building a birdhouse with a tape measure or manufacturing engine parts with a micrometer, the right 量具 turns guesswork into certainty.

Remember: The most expensive tool isn’t always the best—choose based on your needs:

- DIY → Speed square + tape measure + vernier caliper.

- Metalworking → Digital caliper + micrometer + dial indicator.

- Industrial → Digital protractor + surface roughness tester + gauge blocks.

With the right tools and care, you’ll never have to say “close enough” again.