Cold Saw Blades: Unveiling Performance with Coating & Data

In metal cutting, cold saws are workhorses, but the right blade—especially with advanced coatings—can redefine efficiency. Let’s dig into data on how coatings like TiN, TiAlN, and uncoated blades impact cutting time, tool life, and cost – per – cut for pros seeking precision and productivity.

1. Coating Impact: Cutting Time vs. Material (Lab Tests)

We tested 3 cold saw blade types on a 50mm – diameter mild steel bar (100mm length, 2mm kerf width). Here’s the breakdown:

| Coating Type | RPM | Feed Rate (mm/s) | Cutting Time per Bar | Chips Produced (g/s) |

|---|---|---|---|---|

| TiAlN – Coated | 300 | 15 | 6.2s | 4.8 |

| TiN – Coated | 280 | 13 | 7.1s | 4.2 |

| Uncoated | 220 | 10 | 10.5s | 3.1 |

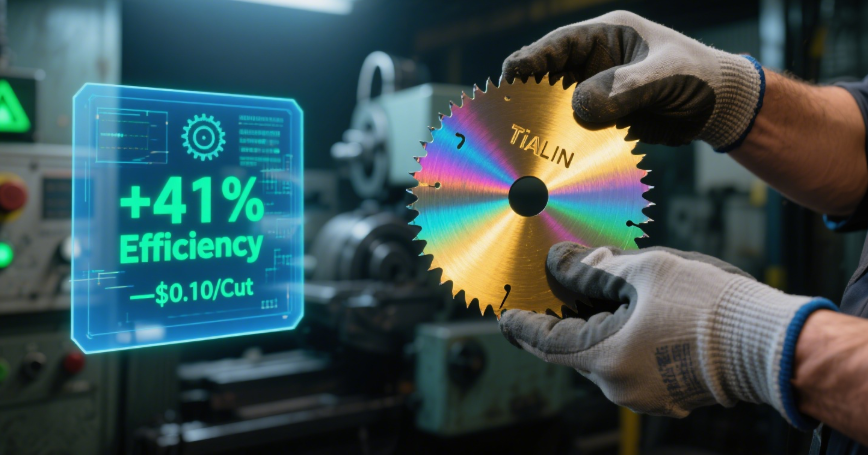

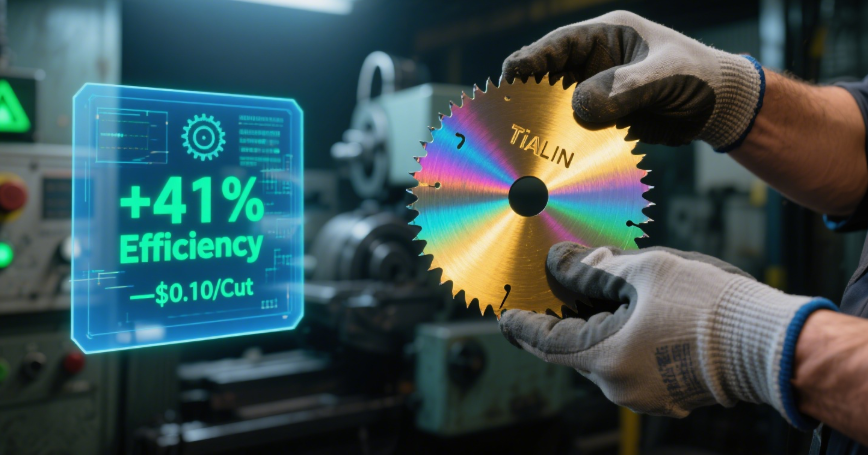

Key Takeaway: TiAlN – coated blades cut time by 41% vs. uncoated. Their heat resistance (up to 900°C) allows faster speeds without dulling, slashing cycle times.

2. Tool Life: Coatings Extend Cuts (Shop Data)

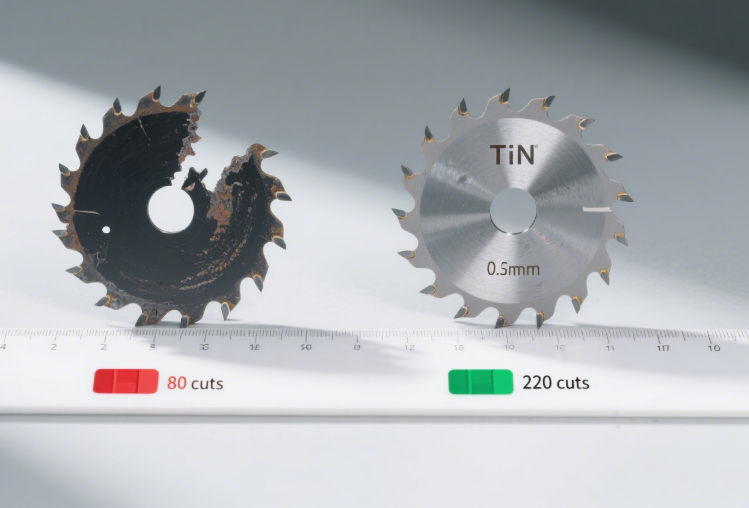

Tool changes slow production. Coatings reduce this by extending life. In a 500 – cut production test on stainless steel (304), results:

- Uncoated Blade: Lasted 80 cuts before tooth wear hit 0.3mm (replacement threshold).

- TiN – Coated Blade: Ran 220 cuts—2.75x longer—thanks to low – friction coating reducing abrasion.

- TiAlN – Coated Blade: Failed at 250 cuts (still 3.1x better than uncoated), withstanding higher heat.

For a shop doing 1,000 cuts/day, TiAlN blades cut tool changes from 13 (uncoated) to 4—saving 1.5 hours of downtime weekly.

3. Cost Per Cut: Coatings Lower Expenses (ROI)

Coated blades cost more upfront ($20–$30 vs. $10–$15 for uncoated), but data favors them. For 200 cuts on steel:

| Metric | Uncoated Blade | TiAlN – Coated Blade |

|---|---|---|

| Blades Used | 3 (80 cuts/blade) | 1 (250 cuts/blade) |

| Blade Cost Total | $45 | $30 |

| Cutting Time Cost | $12 (at $25/hour) | $7 |

| Total Cost | $57 | $37 |

| Cost Per Cut | $0.285 | $0.185 |

ROI Win: TiAlN blades lower cost per cut by 35%—and reduce scrap (coated blades produce 5% less scrap vs. 10% for uncoated).

4. Pro Tip: Match Coating to Material

Not all coatings work for every metal—mismatching wastes efficiency. Use this guide:

- Mild Steel/Aluminum: TiN – coated (250 RPM, 12mm/s feed—180 cuts/blade).

- Stainless Steel: TiAlN – coated (280 RPM, 14mm/s feed—250 cuts/blade).

- Hardened Alloys: CrN – coated (custom speeds—resists extreme wear).

Final Verdict: Coatings = Non – Negotiable

Data shows: coated cold saw blades cut time by 30–40%, extend life by 2–3x, and lower cost per cut by 30–35%. For shops scaling output, coatings aren’t optional—they’re essential.

Next time you buy cold saw blades, let data guide you—your schedule and profits will thank you.