MGMN Carbide Parting and Grooving Inserts: Precision Tools for Machining Excellence

In the realm of CNC lathe machining, few tools match the precision and efficiency of MGMN carbide parting and grooving inserts. Engineered for tackling stainless steel and various steel parts, these inserts are indispensable for creating precise grooves, slots, and clean part separations. This blog explores their specifications, usage, applications, and why they’re a go-to choice for machinists.

What Are MGMN Carbide Inserts?

MGMN inserts are specialized cutting tools made from tungsten carbide alloy—a material renowned for its hardness, wear resistance, and ability to withstand high temperatures during machining. Their design focuses on:

- Geometric Precision: Featuring sharp, well-defined cutting edges to ensure clean cuts.

- Alloy Durability: Tungsten carbide construction allows them to resist chipping and wear, even when machining tough materials like stainless steel.

- Versatility: Compatible with a range of CNC lathes and turning tools, making them adaptable to diverse machining tasks.

Key Specifications: Matching Inserts to Your Needs

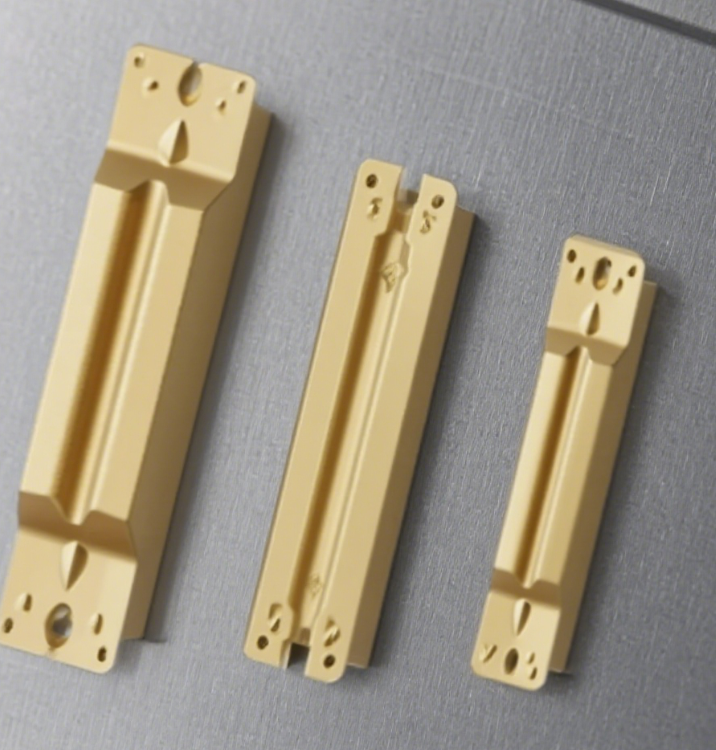

MGMN inserts come in various sizes and configurations to suit different machining requirements:

Size Variations

- Narrow Widths (e.g., 1mm, 2mm): Ideal for creating fine grooves or narrow slots in precision components (e.g., medical instruments, small automotive parts).

- Medium Widths (e.g., 3mm, 4mm): Suited for general grooving and parting tasks in industrial parts like hydraulic fittings or engine components.

- Wide Widths (e.g., 5mm+): Designed for heavy-duty parting (separating large workpieces) or machining deep grooves in thick steel parts.

Coating Options

Many MGMN inserts feature TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) coatings:

- TiN: Enhances surface hardness and reduces friction, ideal for general steel machining.

- TiAlN: Offers superior heat resistance, perfect for high-speed machining of stainless steel (which generates significant heat).

How to Use MGMN Inserts: Best Practices

Using MGMN inserts effectively requires attention to setup and machining parameters:

- Secure Mounting: Install the insert into a compatible tool holder (e.g., a grooving or parting tool holder) using clamping screws. Ensure the insert sits flush and the cutting edge aligns precisely with the workpiece’s axis.

- Adjust Speeds & Feeds:

- For stainless steel: Use moderate speeds (80–150 m/min) and controlled feed rates (0.05–0.2 mm/rev) to manage heat and prevent work hardening.

- For mild steel: Higher speeds (150–250 m/min) and faster feeds (0.1–0.3 mm/rev) can be used for efficiency.

- Coolant Usage: Employ flood coolant or high-pressure mist to lubricate the cutting zone, flush away chips, and reduce thermal stress on the insert.

- Depth of Cut: When grooving, match the insert width to the desired groove size. For parting, ensure the insert’s length is sufficient to cut through the workpiece without bottoming out prematurely.

Primary Applications: Where MGMN Inserts Excel

MGMN carbide inserts shine in scenarios demanding precision and efficiency:

1. Grooving in Stainless Steel Components

Stainless steel is widely used in food processing, medical, and aerospace industries. MGMN inserts create clean, burr-free grooves in parts like:

- Surgical instrument shafts.

- Food-grade pump components.

- Aerospace fasteners.

2. Parting (Separating) Workpieces

When manufacturing parts in bulk (e.g., bolts, pins, or bushings), MGMN inserts efficiently part long workpieces into individual components. Their durability ensures consistent cuts without frequent tool changes.

3. Slotting in Industrial Parts

From hydraulic cylinder slots to gear hub recesses, MGMN inserts produce accurate slots in heavy-duty steel parts. Their wear resistance maintains precision even during prolonged machining runs.

Why Choose MGMN Carbide Inserts?

- Long Tool Life: Tungsten carbide construction and advanced coatings ensure MGMN inserts outlast HSS (High-Speed Steel) alternatives—reducing downtime for tool changes.

- Precision Results: Clean, sharp cutting edges deliver high-quality surface finishes and tight tolerances (often ±0.01mm), eliminating the need for post-machining finishing.

- Cost Efficiency: While upfront costs are higher than HSS, their durability and precision make them cost-effective for high-volume or precision machining.

Whether you’re machining medical devices, automotive parts, or industrial components, MGMN carbide parting and grooving inserts offer the precision, durability, and versatility needed to excel in stainless steel and steel machining. Invest in the right insert size and coating, master your setup, and elevate your machining productivity.