Solid Blue Carbide Endmills: Precision Tools for Hard Metal Machining

In the realm of metalworking, few tools combine durability and precision like solid blue carbide endmills. Designed for CNC machines and high-performance metal cutting, these square-face milling cutters are engineered to tackle hard materials—from medium-hard steel to ultra-tough alloys—with remarkable efficiency. This blog dives into their specifications, usage techniques, and real-world applications, highlighting why they’re a staple in modern machining.

What Makes Solid Blue Carbide Endmills Unique?

First, let’s break down the key features that set these endmills apart:

- Solid Carbide Construction: Made from tungsten carbide, a material harder than high-speed steel (HSS), they resist wear even when cutting abrasive metals.

- Blue Coating: The distinctive blue finish is typically a multi-layer coating (like TiAlN or AlCrN), which enhances heat resistance (up to 1,100°C/2,012°F) and reduces friction. This allows faster cutting speeds without overheating.

- Square Face Design: A flat, sharp tip with precise edge geometry ensures clean, straight cuts—ideal for face milling, slotting, or profiling.

Key Specifications: Matching the Endmill to the Material

Solid blue carbide endmills are graded by the hardness of materials they can handle, measured using the Rockwell Hardness Scale (HRC). Here’s how to choose the right one:

1. HRC45 Endmills

- Target Materials: Medium-hard metals like low-alloy steel, cast iron, or annealed tool steel.

- Best For: General-purpose machining, such as cutting slots in engine brackets or finishing structural steel parts.

2. HRC55 Endmills

- Target Materials: Hardened steel (e.g., 4140 alloy steel), stainless steel (304, 316), or high-carbon steel.

- Best For: Automotive components (gear shafts, brake rotors) or industrial fasteners.

3. HRC60–65 Endmills

- Target Materials: High-hardness alloys like tool steel (A2, D2), heat-treated steel, or nickel-based alloys (Inconel 718).

- Best For: Mold making (die cavities), aerospace parts (turbine blades), or precision jigs.

4. HRC70 Endmills

- Target Materials: Ultra-hard materials such as carbide alloys, ceramics, or hardened tool steel (HRC65+).

- Best For: Machining wear-resistant components like cutting dies, bearing races, or industrial punches.

Bonus Specs: Endmills also vary by diameter (3mm to 25mm+), flute count (2-flute for fast chip evacuation, 4-flute for smoother finishes), and length (short for stability, long for deep slots).

How to Use Solid Blue Carbide Endmills: Pro Tips for Optimal Results

These endmills thrive in CNC machines, but proper setup and technique are critical to avoid damage and ensure precision:

- Secure Mounting: Use a rigid collet or endmill holder to clamp the tool—loose fitting causes vibration, which dulls the cutting edges.

- Adjust Speeds & Feeds:

- For HRC45–55: 1,500–3,000 RPM (steel), with a feed rate of 50–150 mm/min.

- For HRC60–70: Slow to 800–2,000 RPM (harder materials), with feeds of 30–100 mm/min to reduce heat buildup.

- Coolant is Key: Use flood coolant or mist cooling to lubricate the cutting zone and flush away chips—this protects the blue coating from thermal damage.

- Depth of Cut: Start with shallow passes (0.5–1x the endmill diameter) for hard materials. Deep cuts risk tool deflection.

- Check for Wear: Inspect the cutting edges regularly. A dull endmill (signaled by excessive heat, rough finishes, or chipping) will damage workpieces.

Primary Applications: Where These Endmills Shine

Solid blue carbide endmills excel in industries demanding precision and durability:

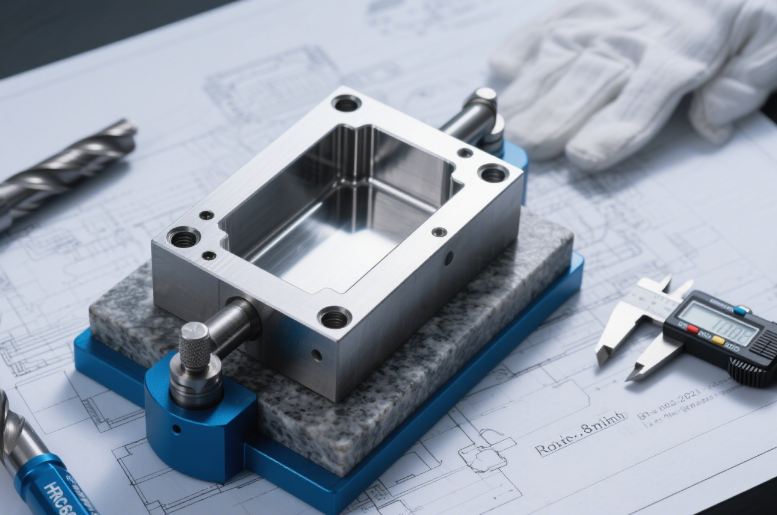

1. Mold & Die Making

Creating cavities in hardened tool steel (HRC55–60) for plastic injection molds or metal stamping dies requires tools that can maintain sharp edges through hours of continuous cutting. HRC60 endmills deliver clean, precise contours, ensuring mold parts fit perfectly.

2. Aerospace Component Machining

Aerospace parts (turbine disks, aircraft brackets) are often made from nickel-based alloys (HRC45–55) or heat-treated steel (HRC60+). These materials resist deformation at high temperatures, so HRC65 endmills—with their heat-resistant coating—are essential for achieving tight tolerances (±0.01mm).

3. Automotive Hard Parts

From hardened gear teeth (HRC58) to brake rotors (cast iron, HRC45), automotive manufacturing relies on blue carbide endmills for fast, consistent machining. Their wear resistance reduces tool changes, boosting production efficiency.

4. Tool & Die Repair

Maintaining industrial tools (punches, dies) made from ultra-hard materials (HRC70) requires HRC70 endmills. They can reshape worn edges without losing precision, extending the tool’s lifespan.

Why Choose Solid Blue Carbide Endmills?

- Longer Tool Life: Carbide + blue coating = 3–5x longer lifespan than HSS endmills in hard materials.

- Faster Production: Higher cutting speeds (thanks to heat resistance) reduce cycle times.

- Superior Finish: Sharp square faces leave smooth surfaces, minimizing the need for post-machining polishing.

Whether you’re machining a 4140 steel bracket or an Inconel turbine part, there’s a solid blue carbide endmill (HRC45 to 70) engineered for the job. Invest in the right grade, master the setup, and watch your hard metal projects reach new levels of precision.