Milling Cutters in Machining: Materials, Methods, and Machinable Workpieces

Milling cutters are indispensable tools in mechanical machining, responsible for shaping metal, plastic, and composite workpieces through rotational cutting. Their performance is defined by material composition, design, and proper usage—all of which directly impact precision, efficiency, and tool life. Let’s explore the key aspects of milling cutters, from their construction to real-world applications.

Milling Cutter Materials: The Backbone of Performance

The material of a milling cutter determines its hardness, heat resistance, and suitability for specific tasks. Here are the most common options:

High-Speed Steel (HSS)

HSS cutters are alloy steels (containing tungsten, molybdenum, and chromium) heat-treated to achieve high hardness (58–65 HRC). They offer:

- Cost-effectiveness: Ideal for low-volume production or hobbyist use.

- Toughness: Resist chipping in interrupted cuts, making them suitable for soft materials.

- Versatility: Can machine mild steel, aluminum, brass, and wood (with proper coatings).

Limitations: They lose hardness at temperatures above 600°C, restricting them to low-speed operations (up to 100 m/min on steel).

Carbide

Carbide cutters consist of tungsten carbide (WC) particles bonded with cobalt (Co). They are categorized into:

- Solid Carbide: Entirely made of carbide, offering extreme hardness (90–92 HRA) and heat resistance (up to 1,000°C). Perfect for high-speed machining of steel, stainless steel, and cast iron.

- Carbide-Tipped: Steel bodies with carbide inserts brazed to the cutting edges. Balances durability and cost, used in heavy-duty face milling of cast iron or alloy steel.

Carbide cutters handle speeds 3–5x faster than HSS, making them essential for mass production.

Ceramic

Ceramic cutters (alumina or silicon nitride-based) excel in high-temperature environments (up to 1,600°C). They are used for:

- Machining hardened steel (45–65 HRC) and superalloys (e.g., Inconel).

- Dry machining (no coolant needed), reducing environmental impact.

Note: Ceramic is brittle—avoid interrupted cuts or heavy vibrations.

CBN (Cubic Boron Nitride)

CBN is second only to diamond in hardness. These cutters are reserved for:

- Ultra-hard materials (60+ HRC), such as tool steel and bearing races.

- Precision finishing where surface roughness (Ra < 0.4μm) is critical.

They maintain sharpness at 1,300°C but are costly and require rigid machines to prevent chipping.

Usage Methods: Maximizing Milling Cutter Performance

Proper technique ensures efficiency and longevity. Key practices include:

Cutting Parameters

- Speed (RPM): Depends on material and cutter type. For example:

- HSS on aluminum: 500–1,000 RPM

- Carbide on steel: 1,000–3,000 RPM

- Ceramic on cast iron: 3,000–6,000 RPM

- Feed Rate: Measured in mm per tooth (fz). Typical values: 0.1–0.3 mm/tooth for finishing; 0.3–0.8 mm/tooth for roughing.

- Depth of Cut (ap): 1–5 mm for end mills; up to 10 mm for face mills (adjust based on cutter diameter).

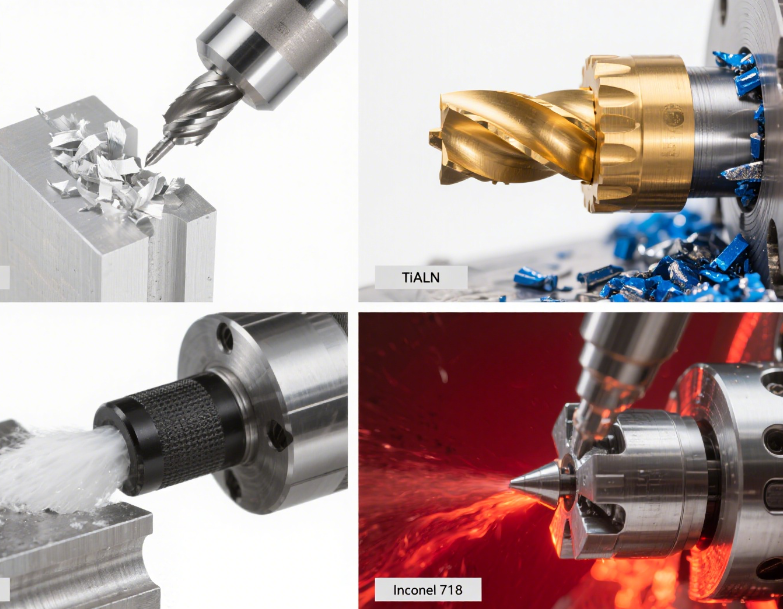

Coolant Application

- Flood Cooling: For HSS and carbide cutters on steel, to reduce heat and flush chips.

- Mist Cooling: For high-speed carbide machining, combining coolant and compressed air for better penetration.

- Dry Machining: Suitable for ceramic or CBN cutters on cast iron (avoids thermal shock).

Cutter Maintenance

- Inspect for wear (chipped edges, dull flutes) regularly—dull cutters increase power consumption and damage workpieces.

- Store in labeled cases to prevent chipping; clean flutes with a brush to remove chip buildup.

Machinable Materials: Matching Cutter to Workpiece

Milling cutters are tailored to specific materials. Here’s how to pair them:

Metals

- Aluminum & Non-Ferrous Metals: HSS or uncoated carbide cutters work well. Use high speeds (1,000–5,000 RPM) and light feeds to avoid built-up edge.

- Mild Steel (1018): Coated carbide (TiAlN) for high-speed finishing; HSS for low-volume roughing.

- Stainless Steel (304): Carbide with coolant to combat work-hardening. Reduce feed rates by 20% compared to mild steel.

- Cast Iron (GG25): Ceramic or carbide-tipped cutters. Dry machining is preferred to prevent graphite smearing.

- Superalloys (Inconel 718): Solid carbide with AlCrN coating, operated at low speeds (300–500 RPM) to manage heat.

Plastics & Composites

- Thermoplastics (ABS, PVC): HSS or carbide cutters with polished flutes to prevent material melting.

- Fiber-Reinforced Polymers (FRP): Diamond-coated carbide to cut through glass or carbon fibers without fraying.

Advanced Designs: Enhancing Versatility

Modern milling cutters feature specialized designs for unique tasks:

- Ball Nose End Mills: Round tips for 3D contouring (e.g., mold making).

- T-Slot Cutters: Create T-shaped grooves for bolts and clamps.

- Shell Mills: Large-diameter face mills for rapid surface finishing.

- Indexable Cutters: Replaceable carbide inserts reduce tool change time in mass production.

Conclusion

Milling cutters are the workhorses of machining, with material and design dictating their performance. Whether using HSS for hobby projects, carbide for high-speed steel machining, or ceramic for hardened alloys, matching the cutter to the workpiece and applying proper techniques ensures precision, efficiency, and long tool life.

In the evolving landscape of manufacturing, understanding milling cutter capabilities is key to unlocking productivity and quality.