BT40 Tool Holders: Material, Efficiency Enhancement, Application, and Beyond

In the realm of CNC machining, BT40 tool holders stand as a cornerstone, playing a pivotal role in ensuring precision, stability, and efficiency during machining operations. Let’s delve into their material composition, how they boost machining efficiency, proper application methods, and other notable benefits.

Material Composition of BT40 Tool Holders

High – Strength Alloy Steel

Most BT40 tool holders are crafted from high – strength alloy steel. This material offers an excellent balance of hardness and toughness. It can withstand the high torque and cutting forces encountered in CNC machining without deforming, ensuring consistent tool positioning accuracy. For instance, alloy steels like SCM420 (a chromium – molybdenum alloy steel) are commonly used, known for their good machinability and heat treatment properties, which allow the tool holder to achieve a high surface hardness while maintaining a tough core.

Surface Treatments

To enhance performance, BT40 tool holders often undergo various surface treatments. Nitriding is a popular choice, which increases the surface hardness and wear resistance. This treatment forms a hard nitride layer on the surface, protecting the tool holder from wear caused by friction with the spindle and tools. Another common treatment is black oxide coating, which not only improves corrosion resistance but also provides a sleek, professional appearance while reducing light reflection in the machining environment.

Enhancing Machining Efficiency with BT40 Tool Holders

High Precision and Repeatability

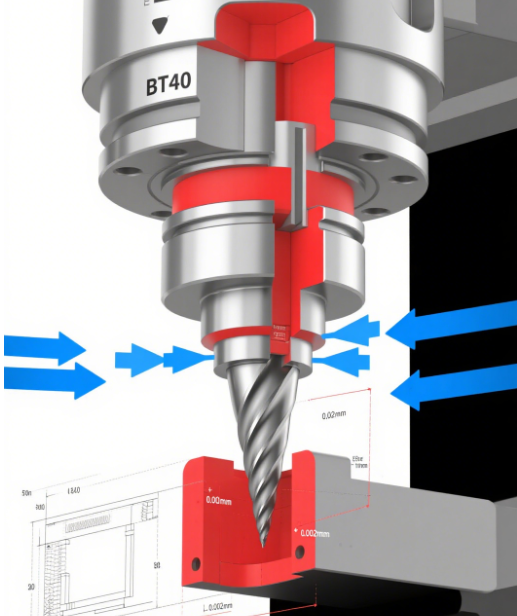

BT40 tool holders feature a tapered shank with a 40 – taper specification, which ensures a precise and rigid connection with the machine spindle. The dual – contact (both taper and face contact) design minimizes runout, typically keeping it within 0.002 mm or less. This high precision means tools can be changed quickly with minimal loss of accuracy, reducing setup times and allowing for faster machining cycles. For example, when switching from a milling tool to a drilling tool, the BT40 holder ensures the new tool is positioned accurately, enabling continuous, efficient production.

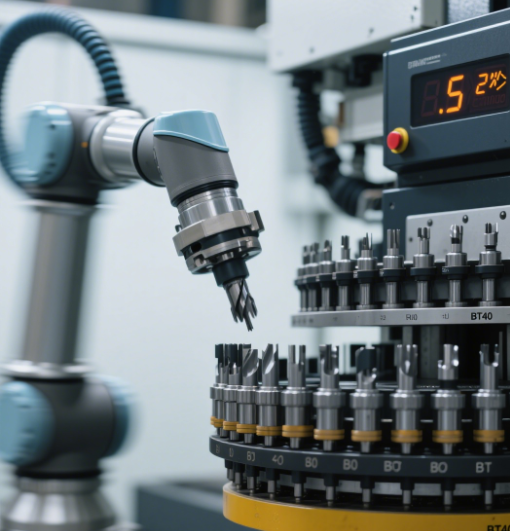

Quick Tool Change

The design of BT40 tool holders is optimized for automated tool changers (ATCs) in CNC machines. Their standardized dimensions and reliable clamping mechanism allow for rapid tool changes, often in just a few seconds. This swift tool change capability is crucial for multi – operation machining processes, where a single part might require multiple tools. By minimizing the time spent on tool changes, overall machining efficiency is significantly increased.

Application Methods of BT40 Tool Holders

Matching with Tools

BT40 tool holders come in various types to accommodate different tools, such as end mill holders, drill chucks, collet chucks, and tap holders. When selecting a BT40 holder, it’s essential to match the holder type to the tool shank diameter and the machining operation. For example, a collet chuck BT40 holder is ideal for holding end mills with cylindrical shanks, providing a secure grip and concentricity. A drill chuck holder is used for drilling operations, allowing for easy adjustment of drill bit sizes.

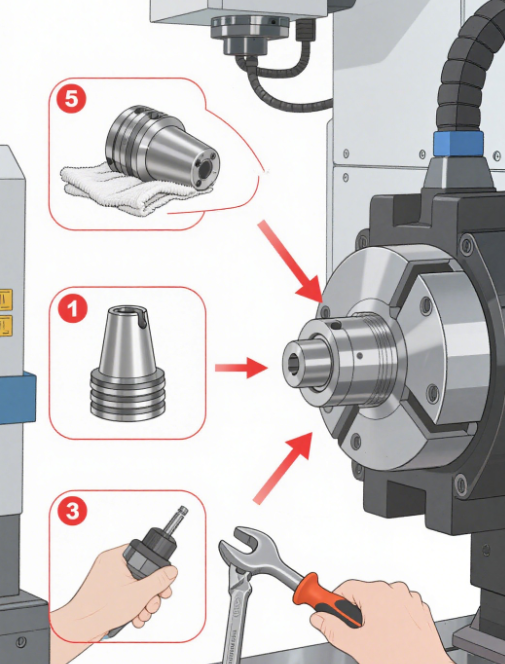

Installation and Handling

Proper installation of BT40 tool holders is vital for safety and performance. The holder should be cleaned before installation to remove any debris that could affect the connection with the spindle. When inserting the holder into the spindle, it should be done smoothly and aligned correctly to ensure the dual – contact is achieved. Additionally, using a torque wrench to tighten the retention knob to the manufacturer’s specified torque ensures the tool is held securely without causing damage to the holder or spindle.

Other Benefits of BT40 Tool Holders

Vibration Damping

Some advanced BT40 tool holders are designed with vibration – damping features. These holders incorporate materials or structures that absorb vibrations generated during high – speed machining. By reducing vibration, they improve surface finish quality, extend tool life, and allow for higher cutting speeds, as less vibration means less stress on both the tool and the workpiece.

Compatibility

BT40 is a widely adopted standard in the machining industry, meaning BT40 tool holders are compatible with a large number of CNC machines from various manufacturers. This compatibility provides flexibility for workshops, as they can use the same holders across different machines, reducing the need for multiple sets of specialized tool holders and simplifying inventory management.

BT40 tool holders, with their robust material construction, efficiency – boosting features, versatile application methods, and additional benefits, are indispensable in modern CNC machining. They form a critical link between the machine tool and the cutting tool, enabling precise, efficient, and reliable production processes.