Q&A: Tools for Processing Special Materials

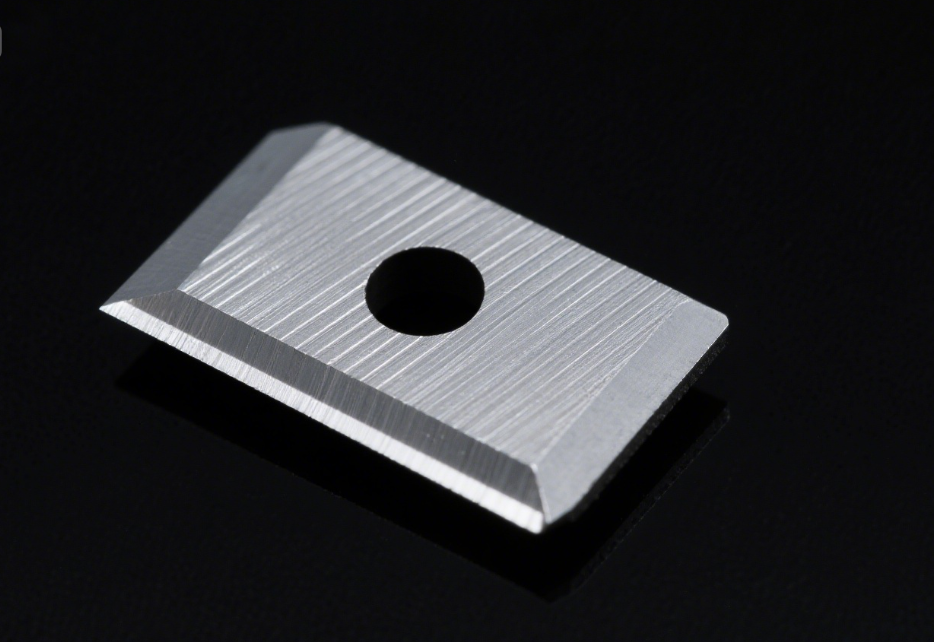

Q1: What blades are suitable for machining high-strength alloys like titanium alloys, and what are the practical cases?

A: Cubic Boron Nitride (CBN) blades are highly suitable for machining high-strength alloys. They have extremely high hardness and wear resistance, second only to diamond, and can maintain good cutting performance at high temperatures.

In the automotive industry, CBN blades are used to machine hardened steel gears. A gear manufacturing plant found that using CBN blades increased machining speed by 30% compared to traditional carbide blades and doubled tool life, reducing overall production costs. In the aerospace sector, when processing titanium alloy compressor blades of aircraft engines, CBN blades ensure the required surface roughness and dimensional accuracy within tight tolerances, thanks to their excellent thermal stability that withstands high temperatures from high-speed machining.

Q2: How to choose drills for drilling in titanium alloys, and are there specific examples?

A: Drilling in titanium alloys is challenging due to low thermal conductivity and high chemical reactivity. Special drills with carbide tips and optimized flute designs are preferred, as they improve chip evacuation and reduce heat generation.

Variable-pitch fluted carbide drills are effective. In a medical implant manufacturing company, these drills are used for drilling holes in titanium alloy implants. The unique flute design quickly evacuates chips, preventing accumulation and tool breakage, while the carbide tips handle high forces and temperatures, ensuring hole accuracy. In aerospace, drills with internal coolant channels are used for titanium alloy aircraft structures. Coolant delivered directly to the cutting edge reduces temperature and improves lubrication, extending drill life and enhancing hole quality for structural integrity.

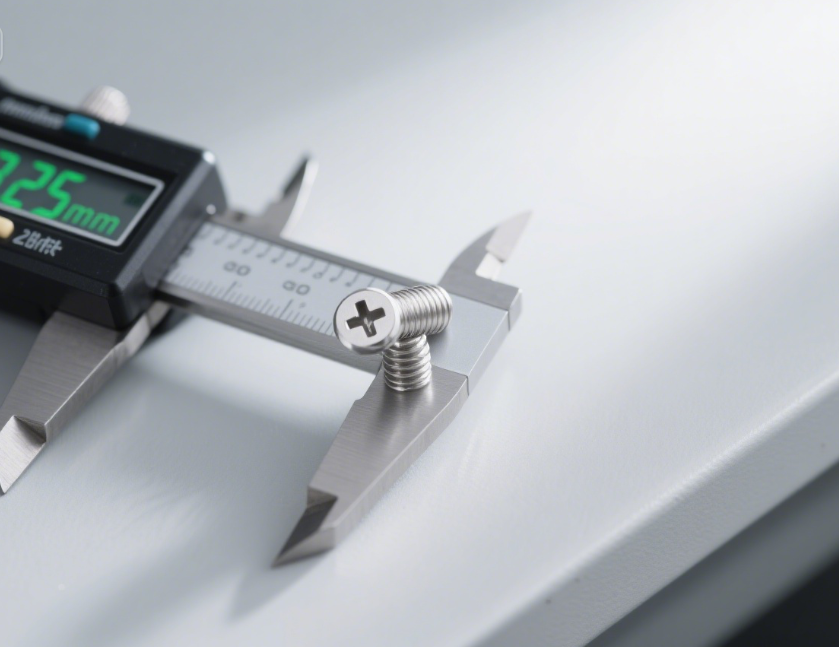

Q3: What calipers work best for measuring high-precision special material parts, and why?

A: High-precision digital calipers with high-resolution sensors are ideal for measuring high-precision special material parts, especially in medical and optical industries.

For medical implants made of special alloys, digital calipers with 0.001mm resolution accurately measure small, complex parts. In a medical device lab, these calipers measure tiny titanium alloy orthopedic screws to micron levels, ensuring proper fit and meeting strict standards. In optics, sub-micron accuracy calipers measure special glass optical lenses. For high-end camera lenses, they precisely check thickness variations, crucial for correct optical power and high-quality images.

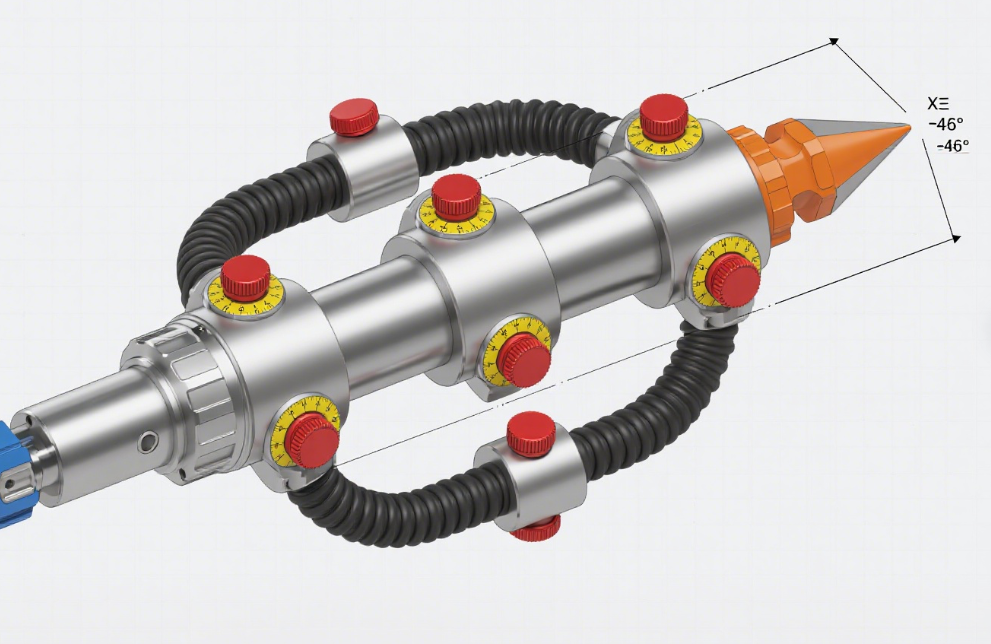

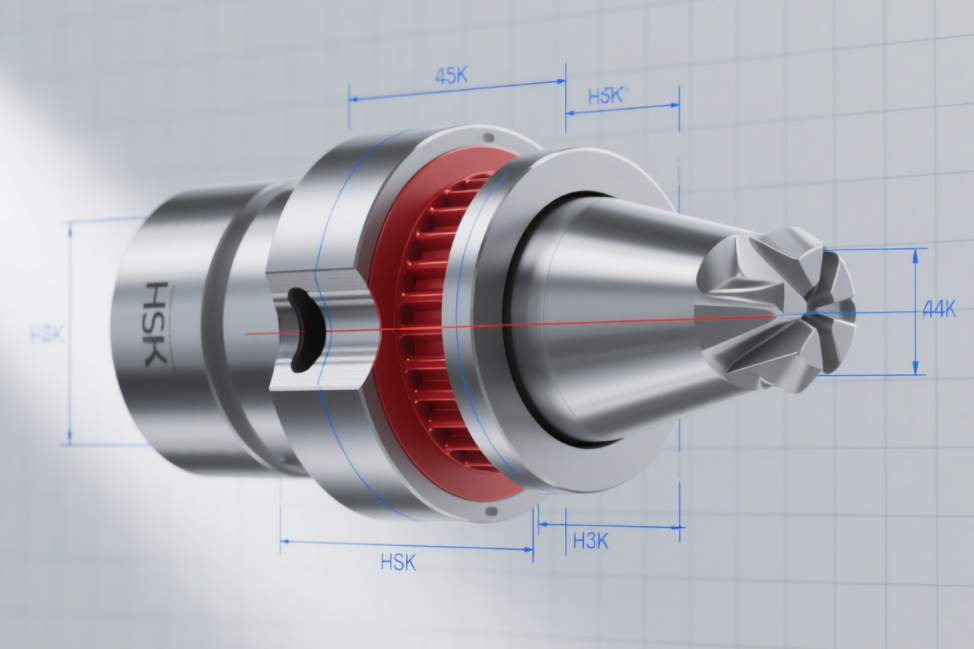

Q4: What toolholders are recommended for high-speed machining of special materials, and what advantages do they offer?

A: HSK (Hollow Shank Toolholder) type toolholders are widely used for high-speed machining of special materials. They provide high-precision clamping and excellent dynamic balance with a short, hollow shank design that fits machine spindles well, ensuring stable tool clamping at high speeds.

In aerospace component manufacturing, HSK toolholders are used with CBN blades for high-speed machining of nickel-based alloys. They maintain stability at 20,000 rpm, enabling accurate machining of complex shapes. In automotive engine production, HSK toolholders hold carbide end mills during high-speed machining of hardened steel components, reducing vibration for high-quality surface finishes, improving performance and durability.

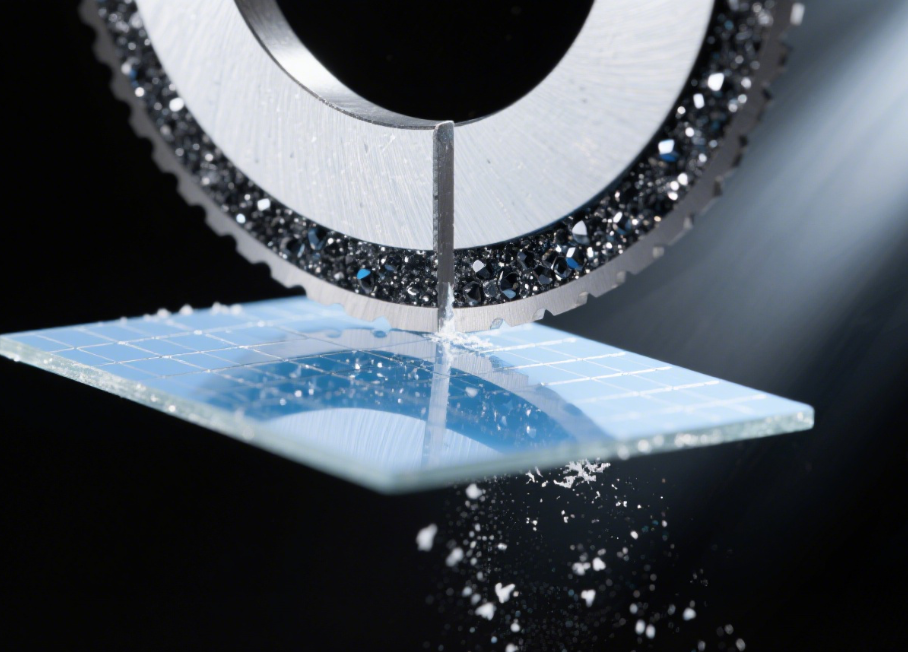

Q5: Which blades are suitable for non-metallic hard materials, and what are their applications?

A: Diamond blades are the top choice for non-metallic hard materials like silicon carbide and glass-fiber-reinforced plastics, thanks to their highest hardness.

In semiconductors, diamond-coated blades dice silicon wafers with cutting widths as narrow as a few micrometers, minimizing waste and preserving chip integrity, vital for high-performance devices. In construction, diamond-tipped circular saw blades cut concrete, stone, and ceramics. For large commercial building renovations, they quickly and accurately cut thick granite floor tiles, with smooth surfaces reducing finishing work, and their durability makes them cost-effective.

Q6: How to select drills for composite materials like CFRP to avoid damage?

A: For composite materials such as CFRP, diamond-coated drills with optimized designs are used to cut fibers without delamination or pull-out, minimizing forces on the material.

Stepped-drill designs work well. In wind turbine blade production (CFRP), diamond-coated stepped drills gradually increase hole diameter, reducing stress and preventing delamination. The coating ensures long wear resistance for repetitive drilling. In automotive, specialized drills with diamond coating and unique point angles reduce thrust force during CFRP component drilling, meeting lightweight and high-strength requirements with efficient, high-quality results.

Q7: What calipers are suitable for heat-sensitive special materials, and why?

A: Calipers made of low-thermal expansion materials like certain stainless steels or ceramics are suitable for heat-sensitive materials, as they minimize temperature-induced measurement errors.

In heat-treatment furnace manufacturing, low-thermal expansion stainless-steel calipers measure heat-resistant alloy components. These calipers resist temperature fluctuations from heating and cooling, providing reliable data for quality control. In semiconductors, ceramic-component calipers measure heat-sensitive wafers. Their extremely low thermal expansion reduces errors from cleanroom temperature changes, ensuring accurate wafer size measurement critical for subsequent chip production.

Q8: What toolholders help with machining complex-shaped special material parts, and how?

A: Flexible toolholders that adjust tool position and angle are needed for complex-shaped special material parts in mold and aerospace industries.

Articulating toolholders machine intricate cavities in heat-resistant alloy molds. In a mold factory, they adjust to various angles, allowing accurate machining of complex curved cavity surfaces, ensuring high-precision molds for quality plastic parts. In aerospace, multi-axis flexible toolholders machine complex titanium alloy aircraft structures. They adjust tool position and orientation in real-time, reducing setups and improving efficiency and accuracy.

Understanding these tool applications helps manufacturers select the right tools for special material processing, ensuring high quality and efficiency across industries.