Milling Cutters: Your Ultimate Guide to Types, Selection, and High-Performance Machining Precision, Efficiency, and Cost Control in Modern Manufacturing

1. What Are Milling Cutters and Why Do They Matter?

Milling cutters are rotary cutting tools mounted on milling machines or CNC centers, designed to remove material from workpieces through multi-point contact. Unlike single-point tools, their intermittent cutting action distributes heat and wear, enabling higher speeds, complex geometries, and superior surface finishes. Key advantages include:

- Versatility: Machine flat, curved, slotted, or threaded surfaces in metals, plastics, and composites.

- Cost Efficiency: Replaceable inserts/extended tool life reduce downtime and consumable costs.

- Precision: Achieve tolerances down to ±0.01 mm for aerospace, automotive, and medical components 38.

2. Types of Milling Cutters: Matching Design to Application

A. By Function & Geometry

Table: Core Milling Cutter Types and Their Industrial Uses

| Type | Best For | Key Features | Industry Use Cases |

|---|---|---|---|

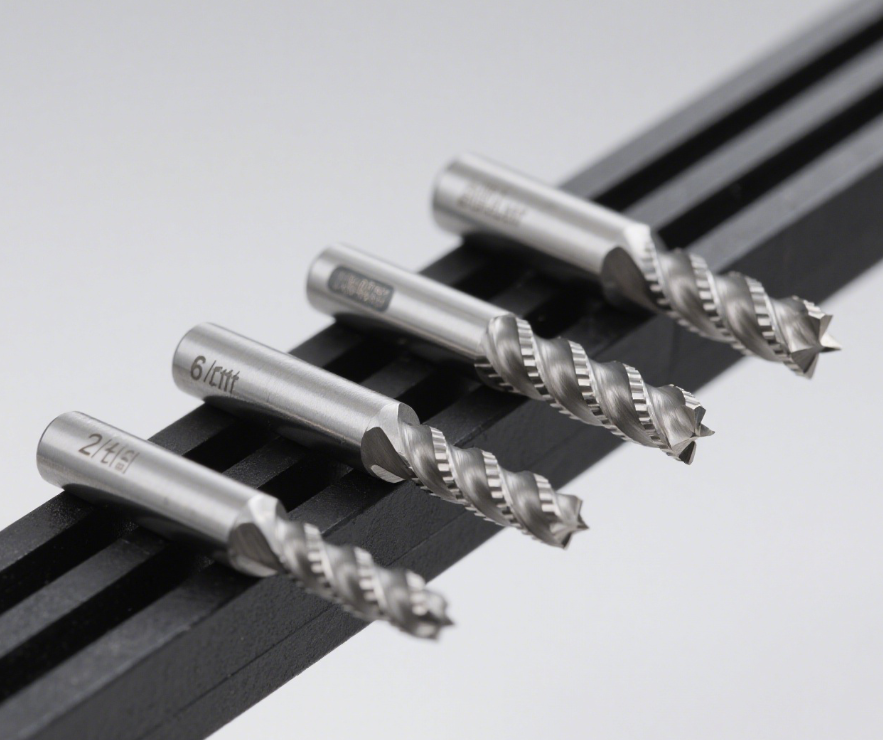

| End Mills | Slotting, profiling, pockets | Cutting edges on end/sides; 2–6 flutes | Mold making, aerospace parts |

| Face Mills | Large flat surfaces | Indexable inserts; diameter = 1.5× spindle size | Automotive blocks, plates |

| Ball Nose Cutters | 3D contours, curved surfaces | Rounded tip; reduces stepover marks | Turbine blades, sculpted dies |

| Thread Mills | Internal/external threads | Single tool for multiple thread sizes | Fasteners, hydraulic fittings |

| T-Slot Cutters | T-shaped grooves | Narrow neck + wide bottom profile | Machine tables, fixtures |

| Shell Mills | Heavy stock removal | Arbor-mounted; replaceable inserts | Casting cleanup, weld removal |

- End Mills subtypes:

- Flat/Square End: Sharp corners for pockets.

- Corner Radius: Rounded edges resist chipping in steel/SS 13.

- Shell Mills: Excel in face milling with 30% faster material removal vs. standard end mills 6.

B. Specialized Cutters

- Roughing End Mills (Rippa Cutters): Serrated edges break chips efficiently for high-feed roughing.

- Dovetail Cutters: Create angled joints for precision slides/fixtures.

- Form Cutters: Machine custom profiles (e.g., gears, convex/concave shapes) 25.

3. Materials & Coatings: Maximizing Tool Life

A. Tool Materials

- Solid Carbide: Ideal for CNC machining; retains hardness up to 1,000°C; resists wear in Ti/Inconel.

- High-Speed Steel (HSS): Cost-effective for soft materials (aluminum, wood); toughness > carbide but wears faster.

- Tungsten Carbide Inserts: Balance wear resistance/impact strength; dominate indexable face mills 49.

B. Performance-Enhancing Coatings

- TiAlN/AlCrN: Reduce heat to 800°C; extend life 200% in steel/stainless steel.

- DLC (Diamond-Like Carbon): Prevent material adhesion in aluminum/copper.

- Nanocomposite Coatings (e.g., TiSiN): For superalloys and dry machining 10.

4. Science of Selection: 4 Principles for Complex Jobs

- 1.Machine Compatibility:

- CNC machining centers → Solid carbide cutters

- Manual mills → HSS or indexable tools 911.

- 2.Workpiece Challenges:

- Vibration/Interrupted Cuts: Use variable helix end mills (uneven flute spacing breaks harmonics).

- Deep Pockets: Necked/reduced-shank end mills minimize deflection.

- Mixed Materials: AlCrN-coated tools handle steel/aluminum zones 10.

- 3.Geometry & Flute Count:MaterialFlute RecommendationHelix AngleAluminum/Plastics2–3 flutes (chip clearance)35°–45°Steel/Stainless4+ flutes (rigidity)30°–40°CompositesDiamond-coated 2-flute10°–20°

- 4.Insert vs. Solid Carbide:

- Roughing: Indexable cutters (economical for large diameters).

- Finishing: Ground solid-carbide end mills for Ra 0.4–1.6 μm finishes 89.

5. Pro Tips: Installation, Optimization & Troubleshooting

A. Setup Best Practices

- Mounting: Clean tapers with acetone; torque holders to 180 N·m for minimal runout (<0.003 mm).

- Parameters:

- Hardened Steel: 120–180 m/min speed; 0.1–0.3 mm/tooth feed.

- Aluminum: 300–500 m/min; 0.2–0.5 mm/tooth feed 67.

B. Extending Tool Life

- Coolant Strategy: Emulsions (8–12%) for aluminum; MQL for hard materials.

- Wear Monitoring: Replace inserts at 0.3 mm flank wear; rotate edges on indexable tools.

C. Solving Common Failures

- Vibration: Use balanced arbors; reduce overhang.

- Edge Chipping: Increase corner radius; lower feed rates.

- Poor Finish: Switch to polished inserts; check runout 610.

6. Future Trends: Smart & Sustainable Tooling

- Sensor-Embedded Cutters: IoT-enabled tools monitor force/temperature in real time (e.g., Sandvik CoroPlus®).

- Eco-Materials: Recyclable carbide (95% tungsten recovery) and SiN bio-ceramics reduce environmental impact.

- Hybrid Designs: 7-channel coolant cutters (e.g., AddMultiTurn) + AI-driven parameter optimization 510.

Key Takeaways for Your Readers:

- 1.Match cutter geometry to operation: Ball nose for curves, face mills for flats, thread mills for precision threads.

- 2.Carbide + coatings dominate CNC: TiAlN for steel; DLC for aluminum.

- 3.Flute count = material-specific: 2–3 for soft metals; 4+ for hard alloys.

- 4.Stability beats size: Smaller diameters with variable helixes outperform oversized tools in complex setups.

Why Publish This?

This guide positions your blog as a manufacturing authority, targeting keywords like “carbide end mill selection” or “CNC milling cutter troubleshooting.” Backed by aerospace and automotive use cases, it bridges theory and shop-floor practicality—ideal for driving organic traffic and engagement.